Method for carrying out cooperated desulfuration and denitration on non-ferrous smelting fume by using cycling sodium-alkali method

A smelting flue gas, desulfurization and denitrification technology, applied in the field of flue gas desulfurization and denitration treatment, can solve the problems of inability to efficiently remove sulfur oxides and nitrogen oxides, lack of synergistic control technology for simultaneous reduction of sulfur and nitrate emissions, and achieve synergy Emission reduction, small flue gas volume, and low flue gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, a self-made rotary furnace is selected as the flue gas generating equipment, and lead concentrate powder and coal are used as mixed raw materials for roasting treatment to provide non-ferrous smelting flue gas close to the actual lead smelting section. Smoke volume is about 200m 3 / h, NO, SO in flue gas 2 The concentrations are 200mg / m 3 and 2000mg / m 3 . After passing through an electrostatic precipitator and an air heat exchanger, the exhaust gas at the outlet of the rotary furnace is introduced into a flue gas oxidation device, and an ozone generator (60g / h) is used to prepare ozone and then passed into the flue gas oxidation device. NO in the air is oxidized to NO 2 , where O 3 The molar ratio of / NO is about 0.9:1. The flue gas oxidized by ozone is introduced into the flue gas absorption tower, with Na 2 SO 3 Absorbing liquid for NO in flue gas 2 , SO 2 to absorb. The liquid-gas ratio of the absorption liquid to the treated flue gas is...

Embodiment 2

[0028] In this embodiment, the above-mentioned experimental system is also selected to carry out experimental research on sulfur / nitrate synergistic emission reduction. The flue gas volume is about 200m 3 / h, NO, SO in flue gas 2 The concentrations are 200mg / m 3 and 2000mg / m 3 . Oxidation of NO in flue gas to NO by ozone 2 , where O 3 The molar ratio of / NO is about 1.1:1. The flue gas oxidized by ozone is introduced into the flue gas absorption tower, with Na 2 SO 3 Absorbing liquid for NO in flue gas 2 , SO 2 to absorb. The liquid-gas ratio of the absorption liquid to the treated flue gas is 5L / m 3 . After monitoring the flue gas after the absorption tower, the results indicate that the treated flue gas NO, SO 2 Concentrations are: 10mg / m 3 and 100mg / m 3 , the flue gas denitrification and desulfurization efficiencies are 95% and 95% respectively.

Embodiment 3

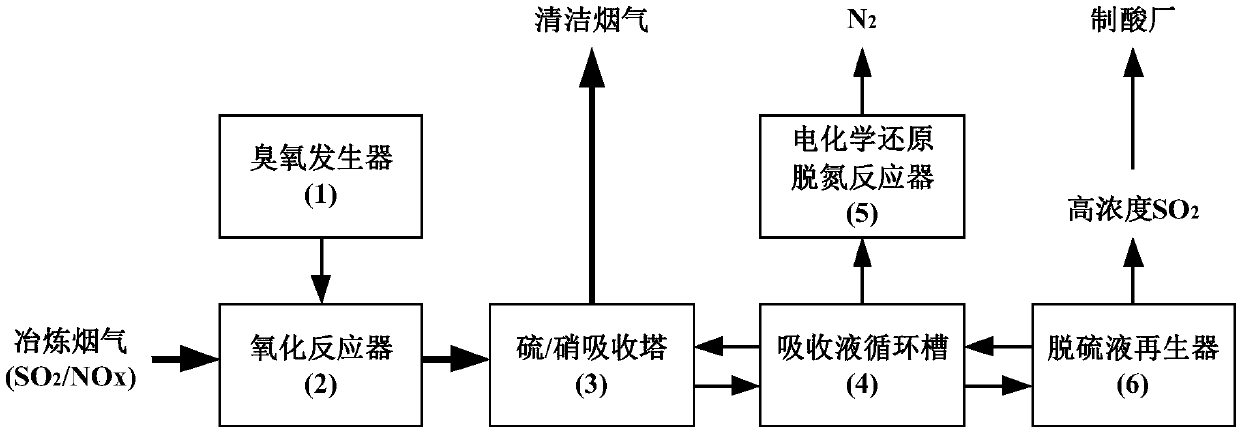

[0030] like figure 1 As shown, a method for synergistic desulfurization and denitrification of non-ferrous smelting flue gas by using the circulating sodium-alkali method includes the following steps:

[0031] In the first step, the smelting flue gas with a temperature of 120-200°C after dust removal and cooling treatment is passed into the oxidation reactor (2);

[0032] In the second step, the ozone generated by the ozone generator 1 is passed into the oxidation reactor 2, and the molar ratio range of the ozone injected into the oxidation reactor 2 per unit time and the nitrogen oxides in the flue gas is 0.5-1.2, and the flue gas is separated by ozone. NO is oxidized to NO 2 ;

[0033] In the third step, the flue gas after the oxidation reaction is passed in the sulfur / nitrate absorption tower 3, and the main absorbent Na 2 SO 3 and enhanced absorbent sodium sulfide on SO in flue gas 2 , NO and NO 2 Simultaneous absorption is carried out, the clean flue gas is discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com