Solid inhibitor addition based method for collaborative emission reduction of SO2 and dioxins in sintering process

A sintering process and inhibitor technology, applied in separation methods, chemical instruments and methods, dispersed particle filtration, etc., to achieve the effect of ensuring air volume and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

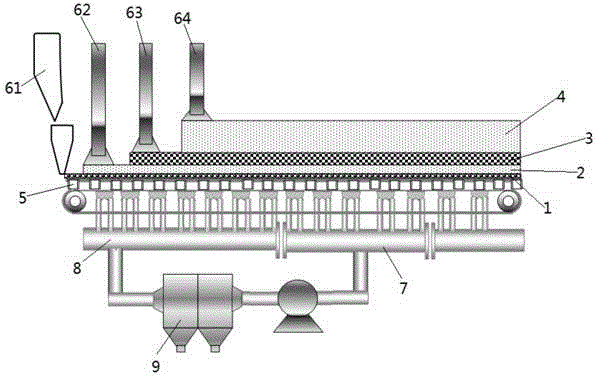

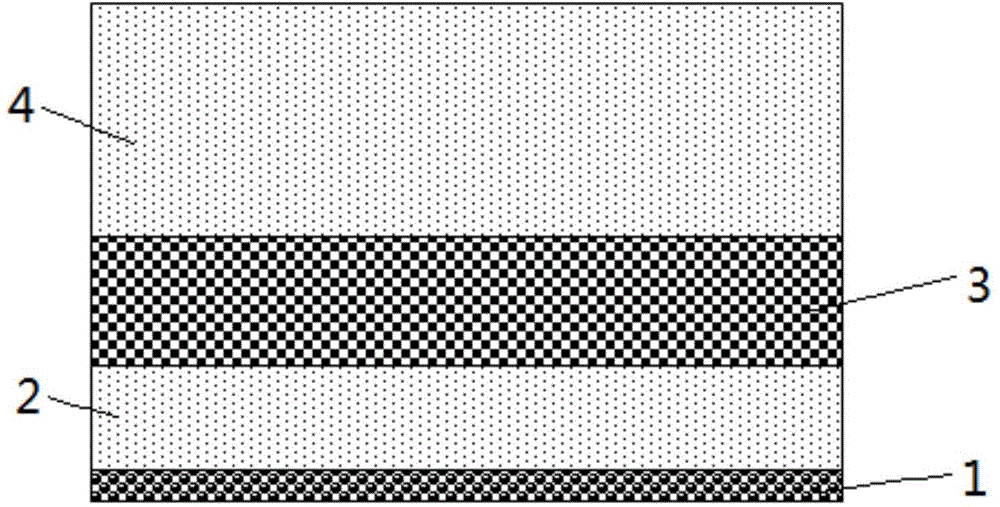

[0044] combine figure 1 , figure 2 and image 3 , a sintering process SO based on the addition of solid inhibitors in this embodiment 2 , The dioxin collaborative emission reduction method, the distribution device is arranged on the upper part of the sintering trolley 5, and the upper part of the sintering trolley 5 is sequentially provided with a bottoming material distribution device 61, a first mixed material distribution device 62, and emission reduction mixture. The distribution device 63, the second mixed material distribution device 64 (such as figure 1 shown), wherein: the bottoming material distributing device 61 is used for paving the bottoming material layer 1 on the upper part of the sintering trolley 5, and the first mixed material distributing device 62 is used for paving the sintering material layer 1 above the bottoming material layer 1. mixture, and form the first mixture layer 2, the total thickness of the bottom layer 1 and the first mixture layer 2 is 9...

Embodiment 2

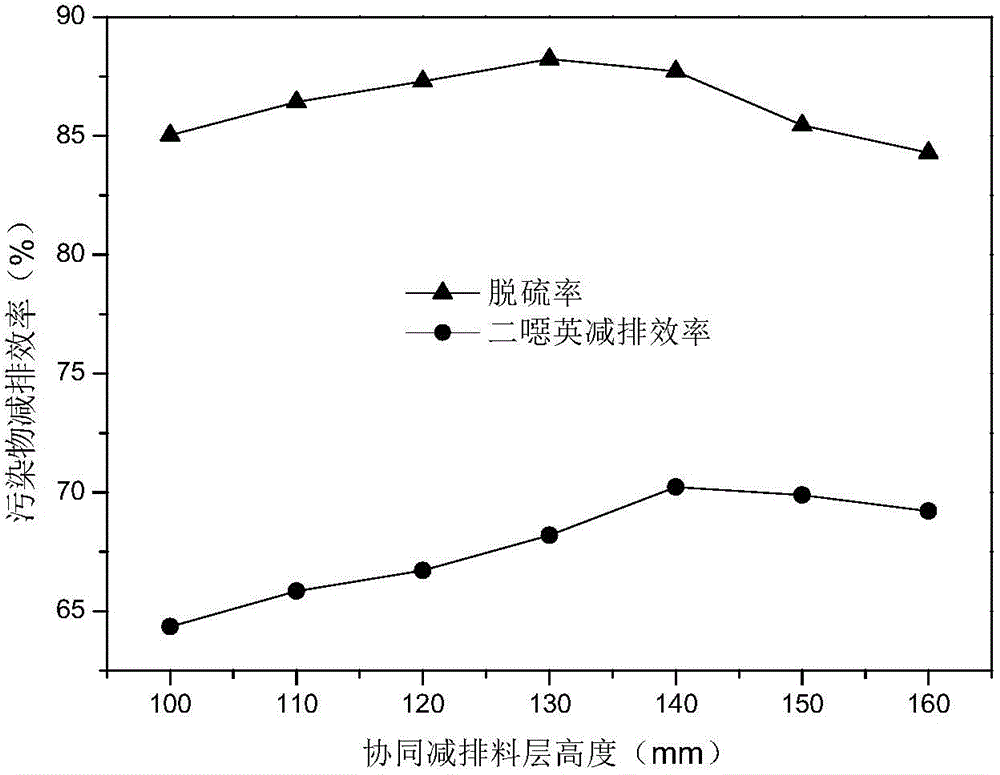

[0081] SO in the sintering process of this embodiment 2 1. The basic process of the method for synergistic emission reduction of dioxins is the same as that of Example 1, except that the bottom layer 1, the first mixture layer 2, the synergistic emission reduction layer 3 and the second mixture layer 4 of the present embodiment The total height of the material layer (the total thickness of the material layer) is 800mm, wherein the thickness of the collaborative emission reduction material layer 3 is 110mm, and the SO 2 , the generation concentration of dioxins, and calculate the desulfurization rate and the emission reduction efficiency of dioxins. The desulfurization rate of the present embodiment is 86.43%, and the emission reduction efficiency of dioxins is 65.84%.

Embodiment 3

[0083] SO in the sintering process of this embodiment 2 1. The basic process of the method for synergistic emission reduction of dioxins is the same as that of Example 1, except that the bottom layer 1, the first mixture layer 2, the synergistic emission reduction layer 3 and the second mixture layer 4 of the present embodiment The total height of the material layer (the total thickness of the material layer) is 800mm, wherein the thickness of the collaborative emission reduction material layer 3 is 120mm, and the SO 2 , the generation concentration of dioxins, and calculate the desulfurization rate and the emission reduction efficiency of dioxins. The desulfurization rate of the present embodiment is 87.29%, and the emission reduction efficiency of dioxins is 66.71%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com