A process of using cement clinker production line to treat domestic waste

A technology for cement clinker and domestic waste, which is applied in the direction of cement production, etc. It can solve problems such as difficult operation, increased air volume of calciner, and difficult layout of kiln tail, so as to improve work quality and efficiency, save waste disposal costs, and benefit The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

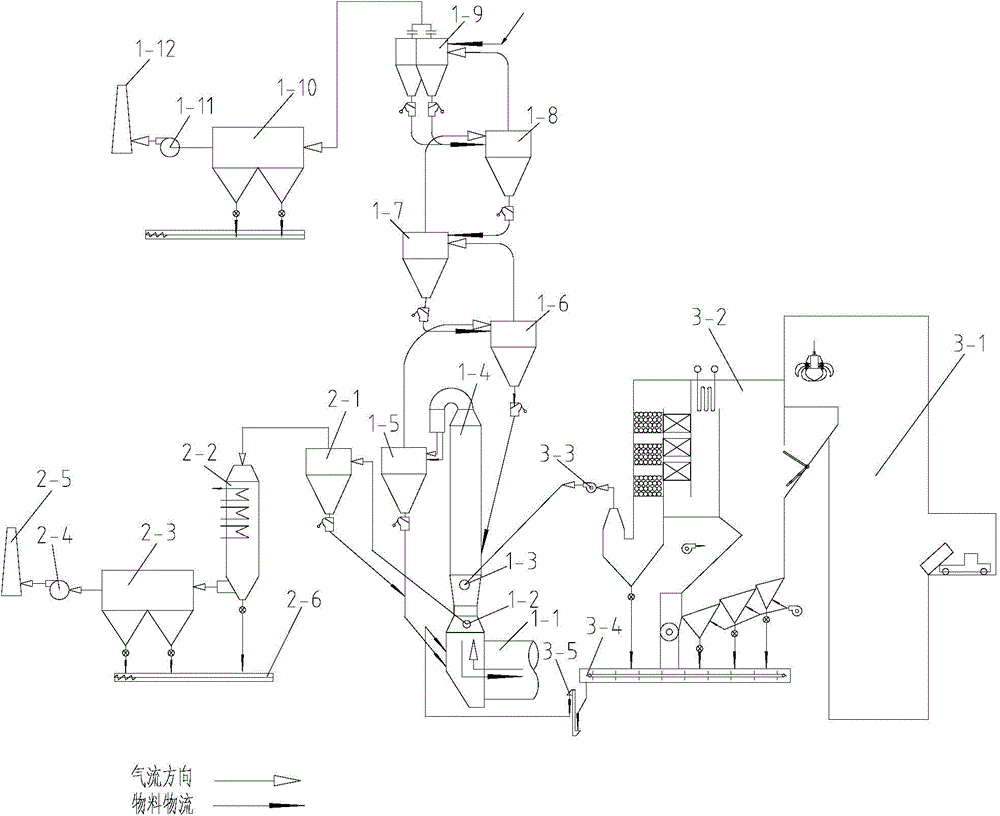

[0021] In the existing cement clinker production line, the flue gas generated by the high-temperature calcination of the cement clinker at the kiln tail 1-1 enters the bypass flue gas dust separator 2 2-1 through the bypass flue gas outlet 1-2 for material gas separation, and passes through The bypass flue gas waste heat boiler 2-2 conducts heat exchange, and discharges up to the standard after being treated by the waste gas treatment system; the flue gas generated by incinerating waste in the waste incinerator 3-2 enters the decomposition furnace 1-4 from the waste gas inlet 1-3 for high-temperature treatment. Decomposition, the decomposed waste gas enters the cyclone separator 5 1-5 for material gas separation, the separated dust enters the kiln tail 1-1, the separated flue gas is separated by the cyclone separator, and the flue gas is treated by the waste gas treatment system Discharge up to the standard; garbage slag enters the kiln tail 1-1 for high-temperature calcination...

Embodiment 2

[0023] In the existing cement clinker production line, after the materials are separated by cyclone 1-9, cyclone 2 1-8, cyclone 3 1-7, and cyclone 4 1-6, the material gas is separated from the material inlet. Enter the calciner 1-4 for pyrolysis, the temperature of the calciner 1-4 in the alkaline atmosphere is 850-900 ℃, the material is decomposed into dust and flue gas and enters the cyclone separator 5 1-5 for material gas separation, and the separated The flue gas is separated from the material gas by cyclone four 1-6, cyclone three 1-7, cyclone two 1-8, cyclone one 1-9, and the flue gas passes through kiln tail dust collector 1-10, The kiln tail fan 1-11 and the kiln tail chimney 1-12 are discharged up to the standard. The material dust separated by the cyclone separator 5 1-5 enters the kiln tail 1-1 and is calcined at a temperature of 1300-1500 ° C. After high-temperature calcination, it becomes cement. material.

Embodiment 3

[0025] After the municipal solid waste is poured into the garbage storage 3-1, the grab grabs the garbage into the garbage incinerator 3-2 for incineration, and the high-temperature flue gas is exchanged through the body waste heat boiler, and the steam generated is used for power generation or heating. The low-temperature flue gas enters the decomposition furnace 1-4 from the waste gas inlet 1-3 through the induced fan 3-3 of the waste incinerator, and the decomposition furnace 1-4 heats and decomposes the waste gas under the temperature of 850-900°C in an alkaline atmosphere , the decomposed exhaust gas enters the cyclone separator five 1-5 for material gas separation, the separated dust enters the kiln tail 1-1, and the separated flue gas passes through the cyclone separator four 1-6, cyclone separator three 1-7, Cyclone separator 2 1-8, cyclone separator 1 1-9 separate the material and gas, and the flue gas is discharged through the kiln tail dust collector 1-10, kiln tail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com