Seed cotton fire behavior detection and treatment device

A processing device and detection device technology, applied in fire rescue, medical science, dentistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

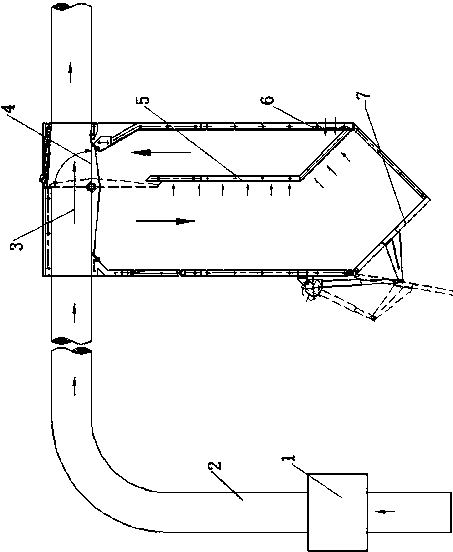

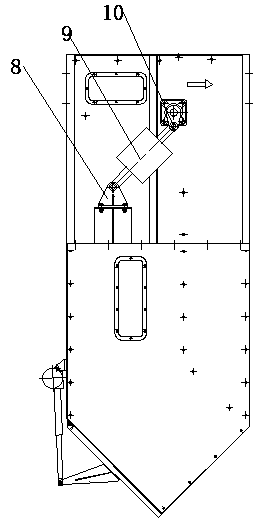

[0023] like figure 1 and figure 2 As shown, the seed cotton fire detection and processing device includes a seed cotton fire detection device 1 for detecting the seed cotton fire in the external suction cotton tube 2 and a seed cotton fire processing device for processing the seed cotton fire. The seed cotton fire treatment device has an inner cavity, the valve plate 4 is placed in the inner cavity, the valve shaft is arranged in the front and back directions, and the valve plates are distributed on both sides of the valve shaft. The inner chamber is divided into an upper chamber 3 and a lower chamber, the upper chamber constitutes a section of the external suction cotton tube, and the lower chamber is built with a partition 5 that divides the lower chamber into a left chamber and a right chamber. When the valve plate is in the first valve position (such as figure 1 As shown by the solid line), the valve plate separates the upper chamber and the lower chamber. When the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com