Cement rotary kiln co-processing domestic waste and energy comprehensive utilization system and method

A cement rotary kiln and collaborative processing technology, applied in cement production, recycling technology, construction waste recycling, etc., can solve the problems of large flue gas volume, high moisture content, low calorific value, etc., to reduce operating costs, simplify processes, The effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

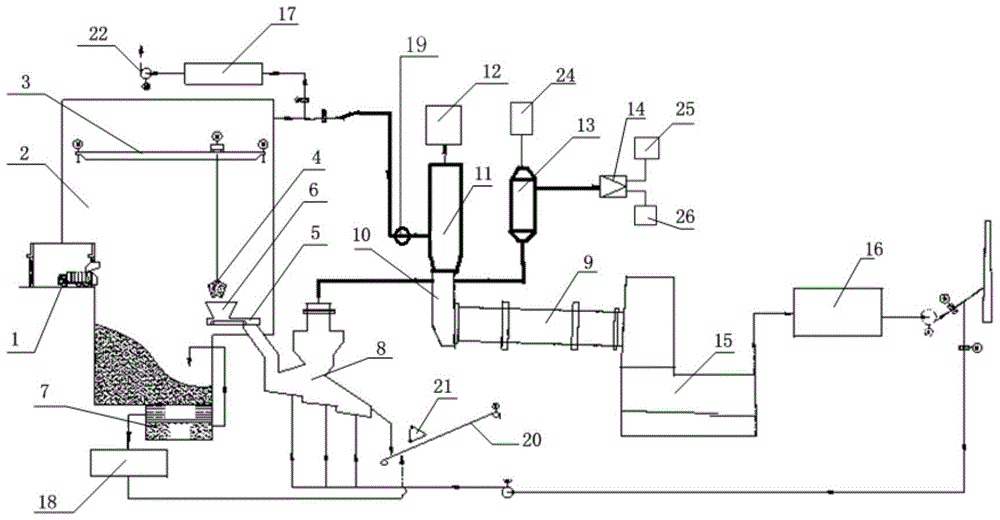

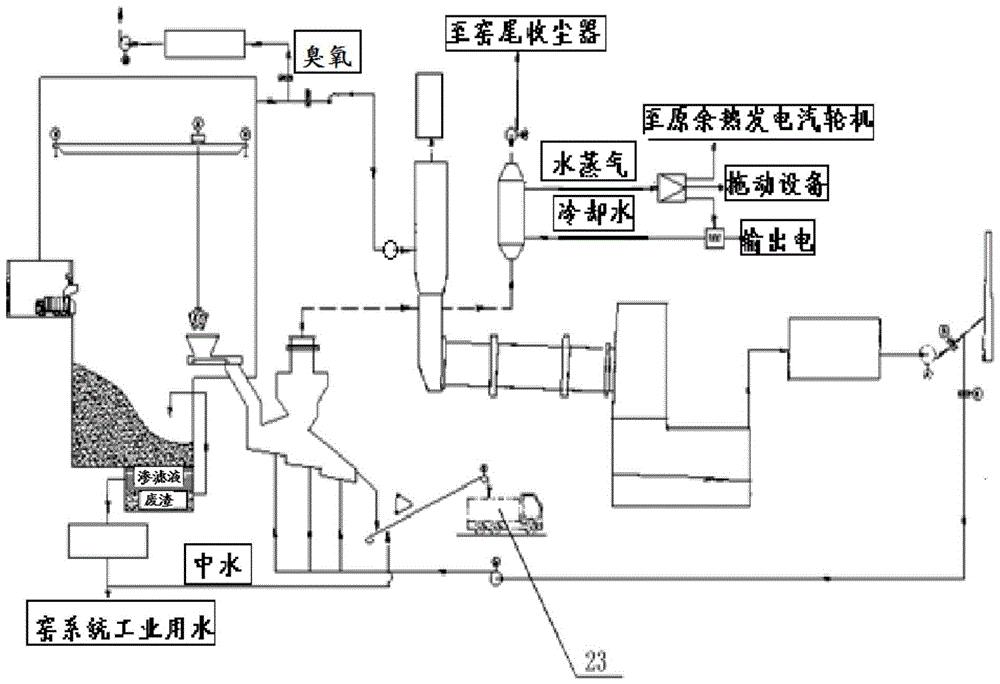

[0043] A cement rotary kiln collaborative treatment of domestic waste and energy comprehensive utilization system, such as figure 1 As shown, it includes garbage metering and storage system, grate furnace 8, rotary kiln 9, decomposition furnace 11, preheater 12, boiler water vapor comprehensive utilization system, grate cooler 15, kiln head dust collector 16, odor treatment System 17 and leachate treatment system 18;

[0044] The grate furnace 8 is connected with the garbage metering and storage system, and one end of the rotary kiln 9 is provided with a kiln tail smoke chamber 10, and the kiln tail smoke chamber 10 and the decomposition furnace 11 are connected to the furnace respectively. The top of the grate fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com