Method for reducing emission of sintering flue gas pollutants by utilizing SCR-containing waste catalyst pellets

A technology of SCR catalyst and waste catalyst, which is applied in the field of reducing sintering flue gas pollutants by using SCR waste catalyst pellets, can solve the problems of reduced emission reduction efficiency, slow temperature rise, etc., to reduce the burden of emission reduction, delay decomposition, and ensure The effect of normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

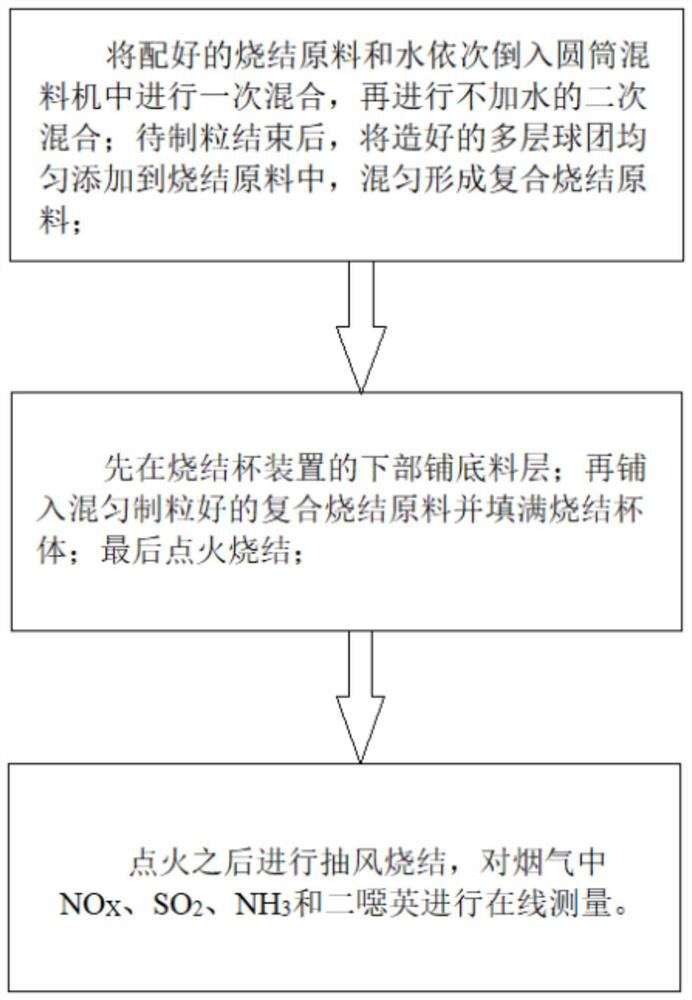

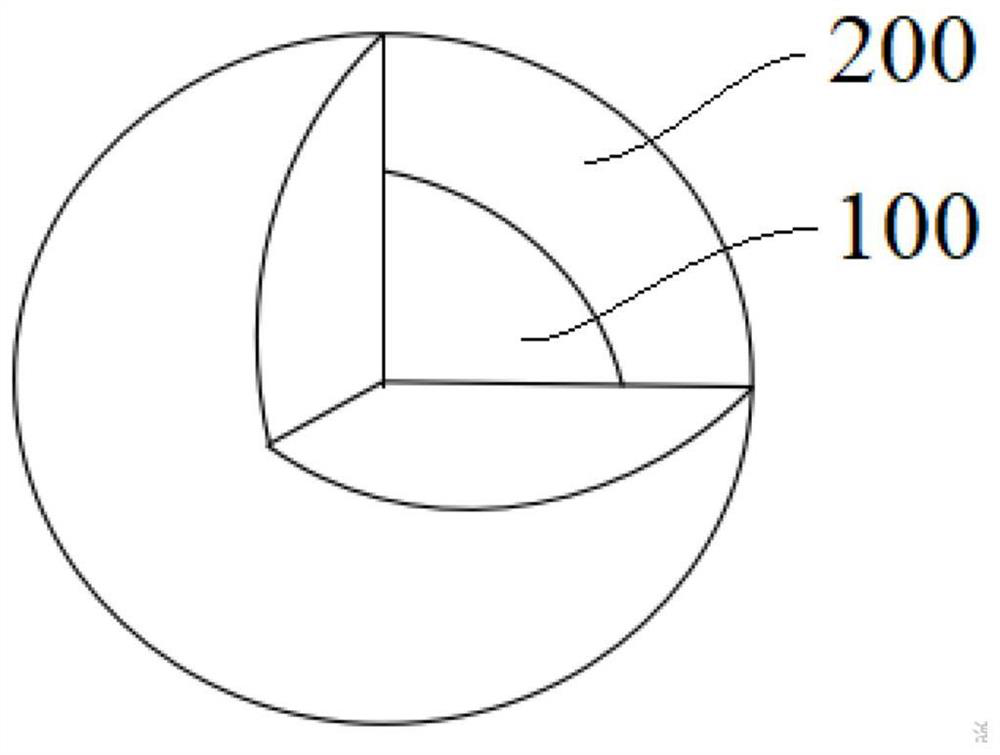

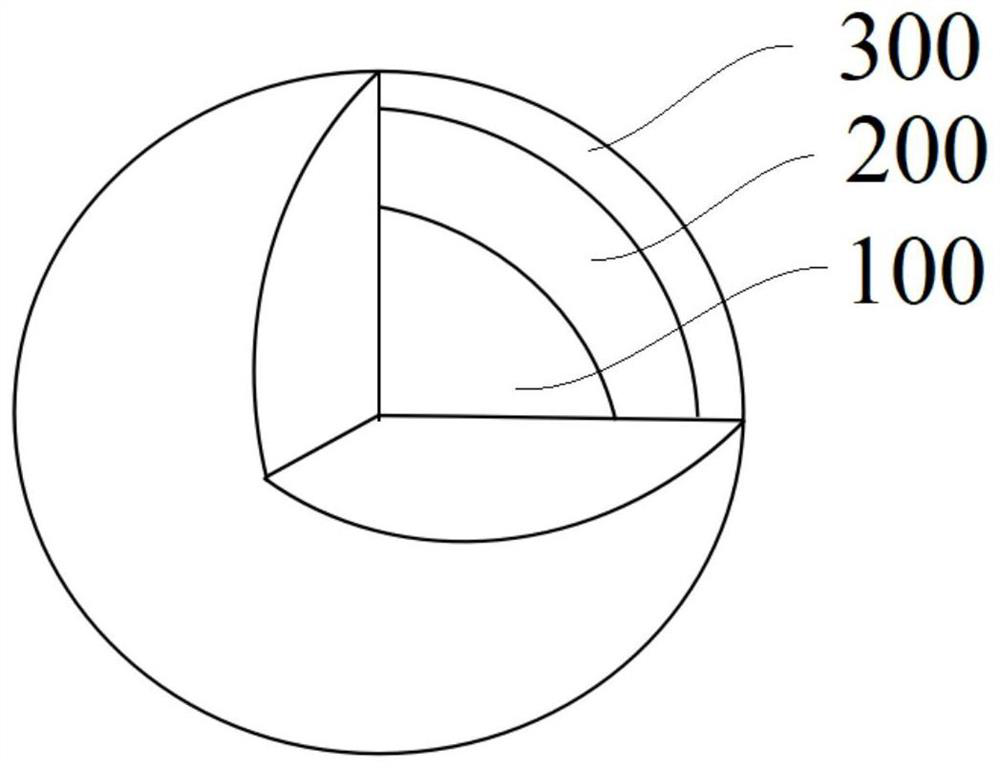

[0043]Such asfigure 1 As shown, a method of adding a sintering ball in the preparation of the SCR discarded catalyst ball to reduce the flue gas contaminant, the sintered raw material is added, and the sintered ball is sequentially provided from the inner layer. The ball group 100, outer ball mass 200 and catalyst layer 300; the inner layer ball group 100 includes ammonia inhibitors, ammonia inhibitors are thermally decomposed to release ammonia; the outer ball group 200 includes a hole The pore agent causes the outer layer ball group 200 in the outer layer ball group 200 in the sintering process; the catalyst layer 300 includes a SCR catalyst and a vanadium titanium blast residue. In the present embodiment, the catalyst layer 300 has a thickness of 2 mm, catalyst layer 300 The SCR catalyst and vanadium titanium blast furnace residue is 1: 1; the SCR catalyst comprises V2O5 and TiO2; the vanadium titanium blast furnace residue comprises CaO, SiO2, and V elements, Ti elements; the in...

Embodiment 2

[0069]The sintered ball of the present embodiment and the sintering emission reduction method are basically the same as that of the first embodiment, and the difference is that the catalyst layer 300 thickness of the present embodiment is maintained at 1 mm, detecting SO2NOXAnd the production concentration of dioxins, records in Table 4, and calculate the desulfurized denitration rate, and the emission reduction efficiency of dioxin.

Embodiment 3

[0071]The sintered ball of the present embodiment and the sintering reduction method are basically the same as that of the first embodiment, and the difference is that the catalyst layer 300 thickness of the present embodiment is maintained at 3 mm, detecting SO2NOXAnd the production concentration of dioxins, records in Table 4, and calculate the desulfurized denitration rate, and the emission reduction efficiency of dioxin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com