Method for preparing methane by deeply purifying landfill gas

A technology for landfill gas and methane production, which is applied in adsorption purification/separation, waste fuel, organic chemistry, etc., can solve the problems of weak PSA research, increased operating costs, increased hydrogen consumption, etc., and achieves low operating costs and equipment. Compact, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

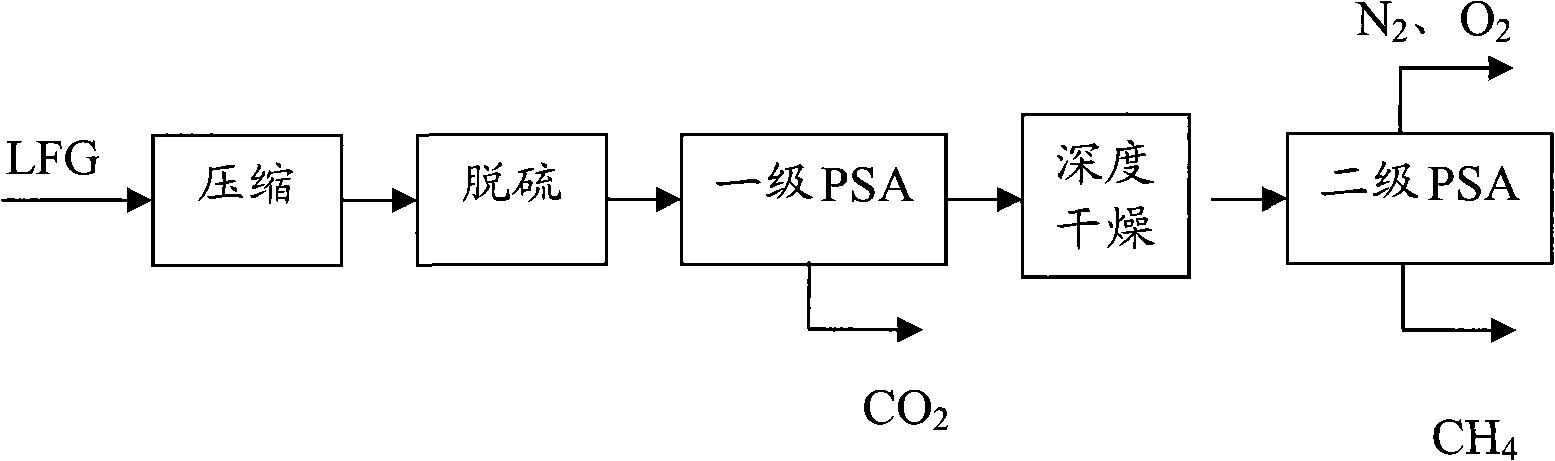

[0066] The present invention includes process steps such as compression desulfurization, pressure swing adsorption decarbonization, deep drying purification and pressure swing adsorption denitrification and oxygen. The schematic diagram of the process is as follows: figure 1 Shown. The specific content of the present invention is described as follows:

[0067] Landfill gas treatment capacity 100Nm 3 / h, its main components are: methane 56.8%, carbon dioxide 38.2%, oxygen 0.7%, H 2 The S content is 56ppm, the CO content is 20ppm, and the total amount of other impurity gases is 4.3%. After the atmospheric landfill gas is compressed to 0.4MPa, the gas enters the desulfurization unit to remove sulfur-containing gas, some moisture, impurity particles, a small amount of acid gas and grease in the landfill gas. After desulfurization, the gas enters the first-stage pressure swing adsorption decarburization system. The pressure swing adsorption system consists of two adsorption towers. The...

Embodiment 2

[0069] Landfill gas treatment capacity 300Nm 3 / h, the main components are: methane 55.6%, carbon dioxide 39.7%, oxygen 0.9%, H 2 The S content is 36ppm, the CO content is 44ppm, and the total amount of other impurity gases is 3.8%. After the atmospheric landfill gas is compressed to 0.8MPa, the gas enters the desulfurization unit to remove sulfur-containing gas, some moisture, impurity particles, a small amount of acid gas and grease in the landfill gas. After desulfurization, the gas enters the first-stage pressure swing adsorption decarburization system. The pressure swing adsorption system consists of 4 adsorption towers. The adsorbent adopts activated alumina / silica gel / molecular sieve with a ratio of 2:6:1, and the adsorption pressure is 0.8MPa , The adsorption temperature is 30 ℃, stop the gas adsorption before the bed penetrates, after the adsorption tower is equalized twice, the adsorption tower is reversely depressurized and evacuated to -0.06MPa, the adsorbent is regene...

Embodiment 3

[0071] Landfill gas treatment capacity 500Nm 3 / h, its main components are: methane 57.2%, carbon dioxide 35.1%, oxygen 0.8%, H 2 The S content is 49ppm, the CO content is 12ppm, and the total amount of other impurity gases is 6.9%. After the atmospheric landfill gas is compressed to 1.2MPa, the gas enters the desulfurization unit to remove sulfur-containing gas, some moisture, impurity particles, a small amount of acid gas and grease in the landfill gas. After desulfurization, the gas enters the primary pressure swing adsorption decarburization system. The pressure swing adsorption system consists of 6 adsorption towers and 1 equalization tank. The adsorbent adopts activated alumina / silica gel / carbon with a ratio of 2:8:1 Molecular sieve, the adsorption pressure is 1.2MPa, the adsorption temperature is 30°C, two adsorption towers are in the adsorption state at the same time during the operation, and the inlet gas adsorption is stopped before the bed penetrates. After the adsorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com