Method for removing trace silicon in high-concentration nickel sulfate solution

A nickel sulfate, high-concentration technology, applied in the direction of nickel sulfate, can solve the problem of incomplete silicon removal, achieve low equipment cost, realize recycling, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

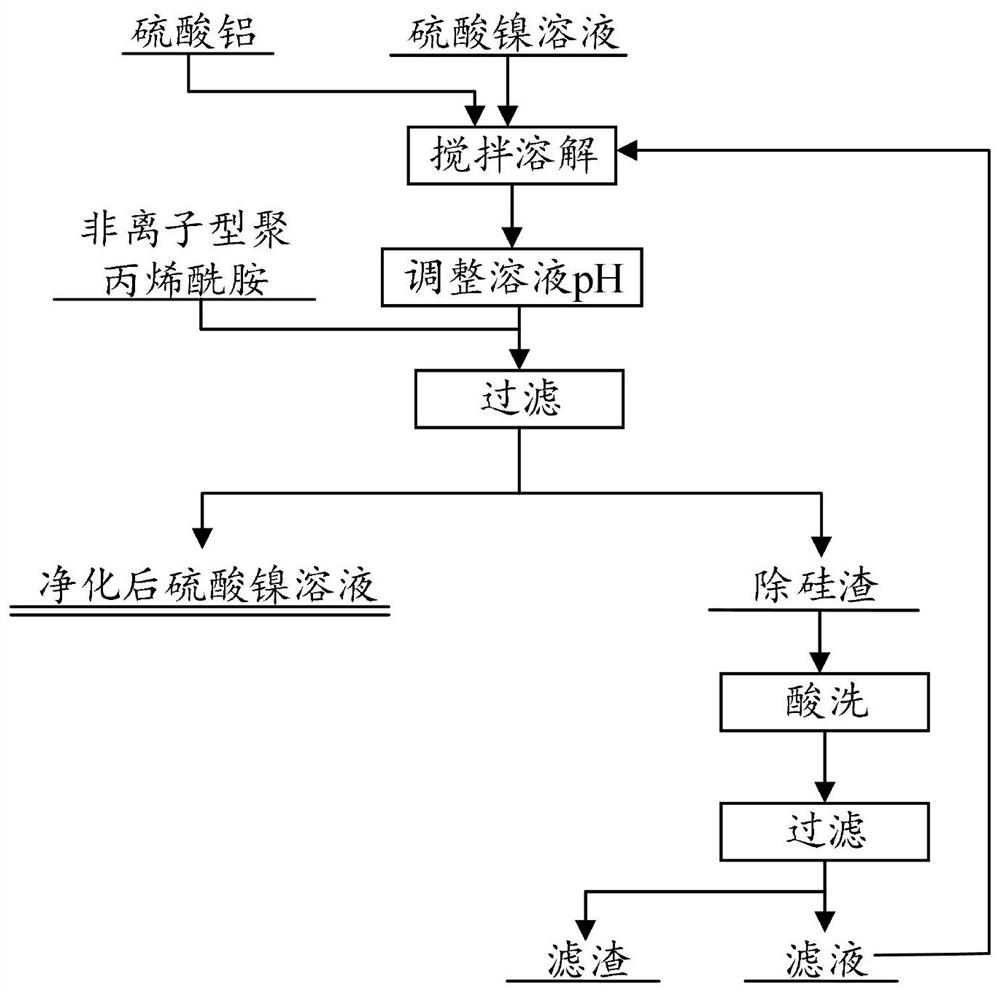

Image

Examples

Embodiment 1

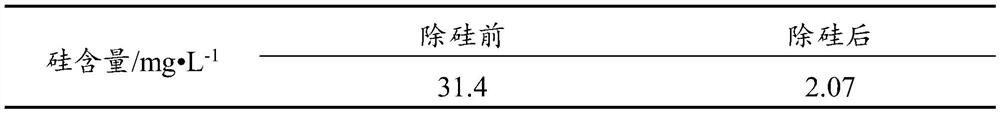

[0024] Place the beaker containing 200mL nickel-containing 120g / L nickel sulfate solution to be treated on the stirrer, adjust the stirrer to a speed of 300rpm, and add 3.6gAl while stirring 2 (SO 4 ) 3 , after reacting for 30 minutes, measure the pH value of the solution and adjust the pH value of the reaction solution to 5.0-5.1 with a certain concentration of NaOH solution by adding dropwise, and filter to obtain the purified nickel sulfate solution and silicon-removing slag, silicon-removing The results are shown in Table 1.

[0025] Table 1 Nickel sulfate solution removes silicon effect and nickel loss rate

[0026]

Embodiment 2

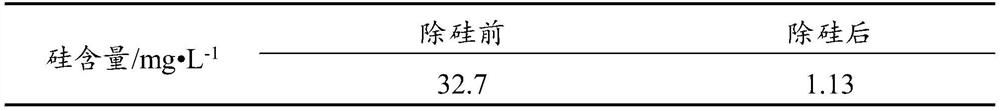

[0028] Place the beaker containing 200mL nickel-containing 85g / L nickel sulfate solution to be treated on the stirrer, adjust the stirrer to a speed of 300rpm, and add 4.0gAl while stirring 2 (SO 4 ) 3 , after reacting for 30 minutes, measure the pH value of the solution and adjust the pH value of the reaction solution to 5.2-5.3 with a certain concentration of NaOH solution by adding dropwise, and filter to obtain the purified nickel sulfate solution and silicon-removing slag, silicon-removing The results are shown in Table 2.

[0029] Table 2 Nickel sulfate solution silicon removal effect and nickel loss rate

[0030]

Embodiment 3

[0032] Place the beaker containing 200mL nickel-containing 106g / L nickel sulfate solution to be treated on the stirrer, adjust the stirrer to a speed of 300rpm, and add 3.6gAl while stirring 2 (SO 4 ) 3 , after reacting for 30 minutes, measure the pH value of the solution and adjust the pH value of the reaction solution to 5.2-5.3 with a certain concentration of NaOH solution by adding dropwise, and filter to obtain the purified nickel sulfate solution and silicon-removing slag, silicon-removing The results are shown in Table 3.

[0033] Table 3 Nickel sulfate solution silicon removal effect and nickel loss rate

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com