Catalyst for synthesizing para diethyl benzene by ethanol and ethyl benzene combination reaction and its preparation method

A technology for p-diethylbenzene and a catalyst is applied in the field of catalysts for synthesizing p-diethylbenzene, can solve the problems of high production cost of diethylbenzene, high content of modified elements, low yield of p-diethylbenzene, etc. The effect of good ethylbenzene selectivity, strong anti-coking ability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

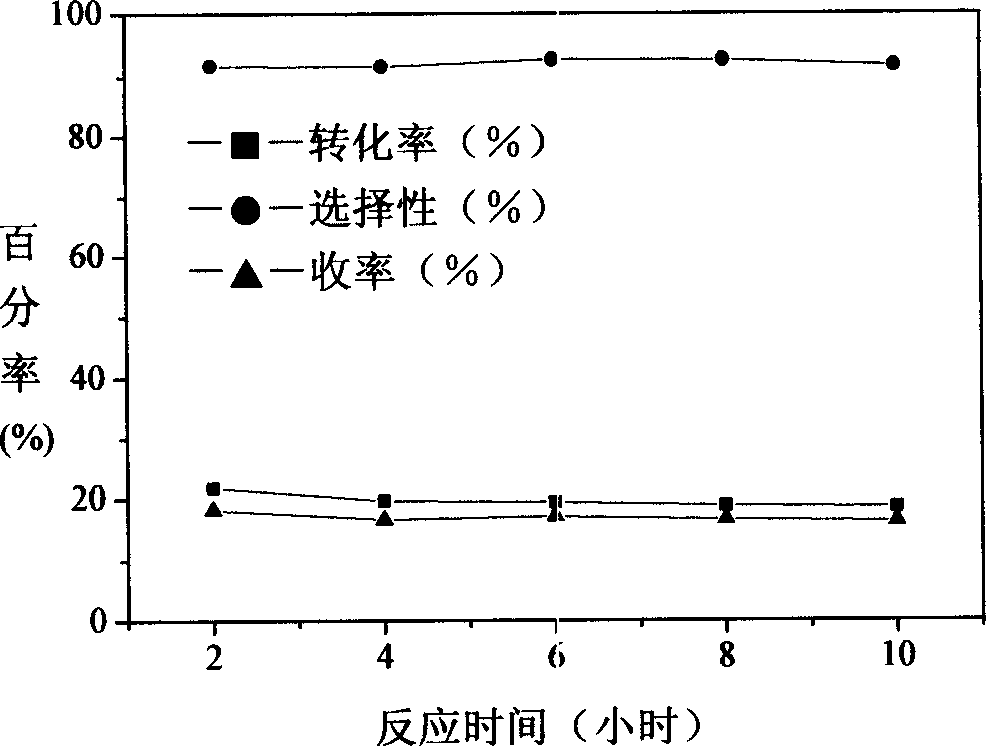

[0020] Example 1 Synthesis of B(1%)-Co(2%)-ZSM-5-01 catalyst

[0021] Weigh 0.5g of cobalt nitrate and 5g of H-ZSM-5 molecular sieve and dissolve in 40ml of distilled water, stir quickly (800r / min) for 10 hours, transfer the mixture to an oven at 80℃ for drying, and then re-dissolve the resulting powder In 40ml of distilled water, add 0.305g of boric acid as the precursor of B, repeat the above steps of stirring and drying, and finally put the obtained powder into a muffle furnace at 550°C for 4 hours and sieving out 400~ The 800 micron catalyst is ready for use.

example 2

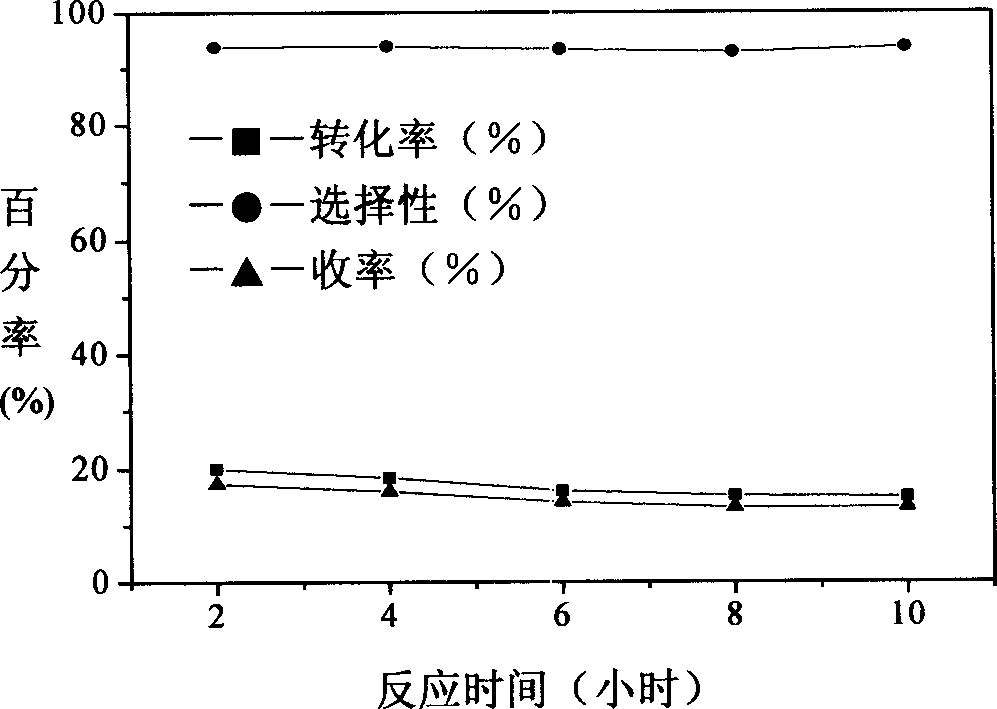

[0022] Example 2 Synthesis of B(1%)-Mg(0.5%)-Co(1%)-ZSM-5-02 catalyst

[0023] Weigh 0.25g cobalt nitrate and 5g H-ZSM-5 molecular sieve and dissolve in 40ml distilled water, stir quickly (800r / min) for 10 hours, then transfer the mixture to an oven at 80℃ for drying, and then re-dissolve the resulting powder Add 0.27g of magnesium nitrate to 40ml of distilled water, repeat the above steps of stirring and drying, and then dissolve the obtained powder in 40ml of distilled water, add 0.305g of boric acid as the precursor of B, and repeat the above steps of stirring and drying again Finally, put the obtained powder into a muffle furnace at 550°C for 4 hours and sieving out a 400-800 micron catalyst for later use.

example 3

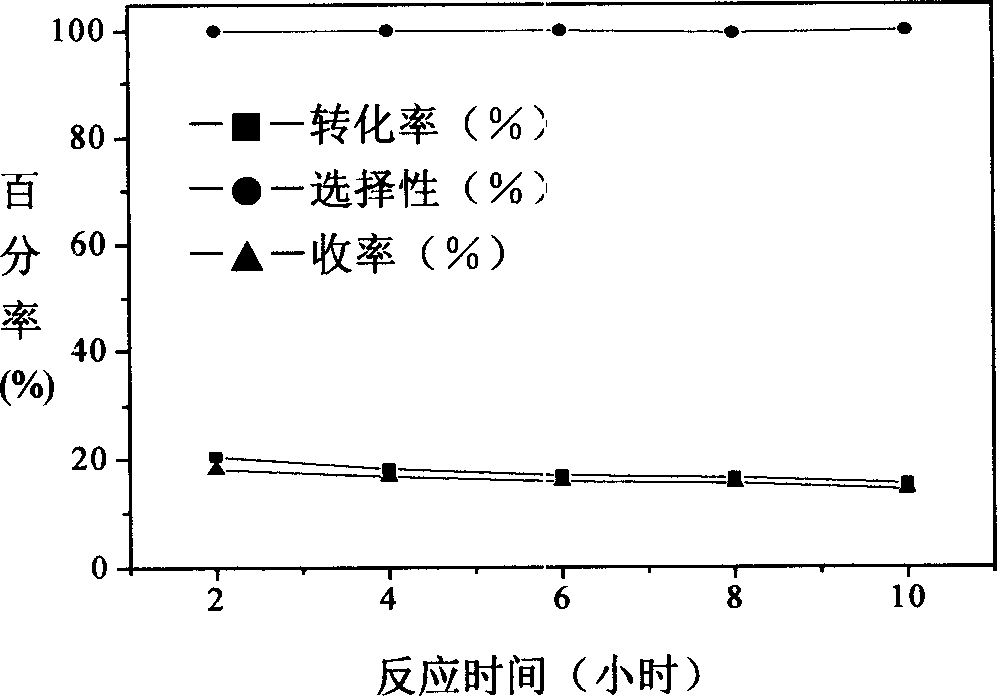

[0024] Example 3 Synthesis of B(1.5%)-Mg(0.5%)-Co(1%)-ZSM-5-03 catalyst

[0025] Weigh 0.25g of cobalt nitrate and 5g of H-ZSM-5 molecular sieve and dissolve in 40ml of distilled water, stir quickly (600r / min) for 10 hours, then transfer the mixture to an oven at 80℃ for drying, and then re-dissolve the resulting powder Add 0.27g of magnesium nitrate to 40ml of distilled water, repeat the above steps of stirring and drying, then dissolve the obtained powder in 40ml of distilled water, add 0.455g of boric acid as the precursor of B, and repeat the above steps of stirring and drying again Finally, put the obtained powder into a muffle furnace at 550°C for 4 hours and sieving out a 400-800 micron catalyst for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com