A device for removing propylene in dry gas and a method for removing propylene in dry gas

A technology for dry gas and propylene, applied in the environmental field, can solve the problems of affecting the reuse of dry gas, waste of components, and large impact on absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

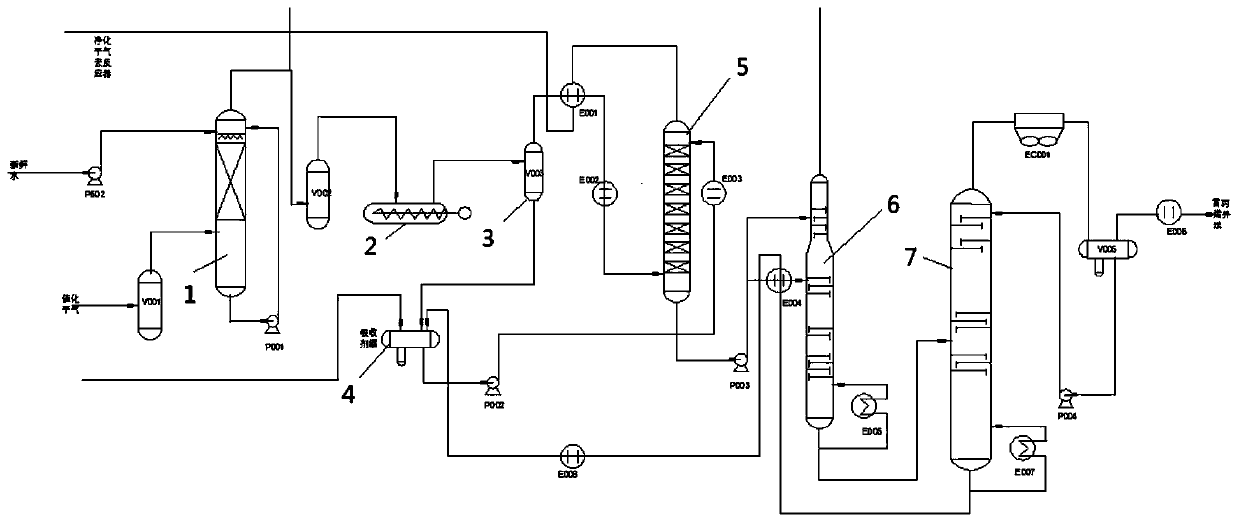

[0083] According to the present invention, the water washing tower (one section of packed tower), dry gas compressor, and buffer tank are connected successively, the outlet at the top of the buffer tank is connected with the propylene absorption tower (seven sections of packing), and the outlet at the bottom of the buffer tank is connected with the absorbent tank; The outlet is connected to the inlet of the propylene absorption tower; the outlet of the propylene absorption tower is connected to the inlet of the deethylene tower (50 trays), the top outlet of the deethylene tower is connected to the inlet of the dry gas compressor, and the bottom outlet of the deethylene tower is connected to the depropylene tower (50 trays). ) connected. The depropylene bottom liquid is returned to the absorbent tank.

Embodiment 2~23

[0085] Connect the device according to Embodiment 1 of the present invention, wash the catalytic dry gas with water in the water washing tower, pressurize the dry gas compressor to 0.8Mpa, buffer it in the buffer tank, and absorb it through the absorbent in the propylene absorption tower to obtain the purified dry gas and absorption at the top of the tower. Tower bottom liquid; benzene and diethylbenzene=87:13 in the absorbent; the bottom liquid of the absorption tower obtains ethylene-rich dry gas and the bottom liquid of the deethylene tower through the deethylene tower; The propylene tower obtains propylene-rich dry gas.

Embodiment 24

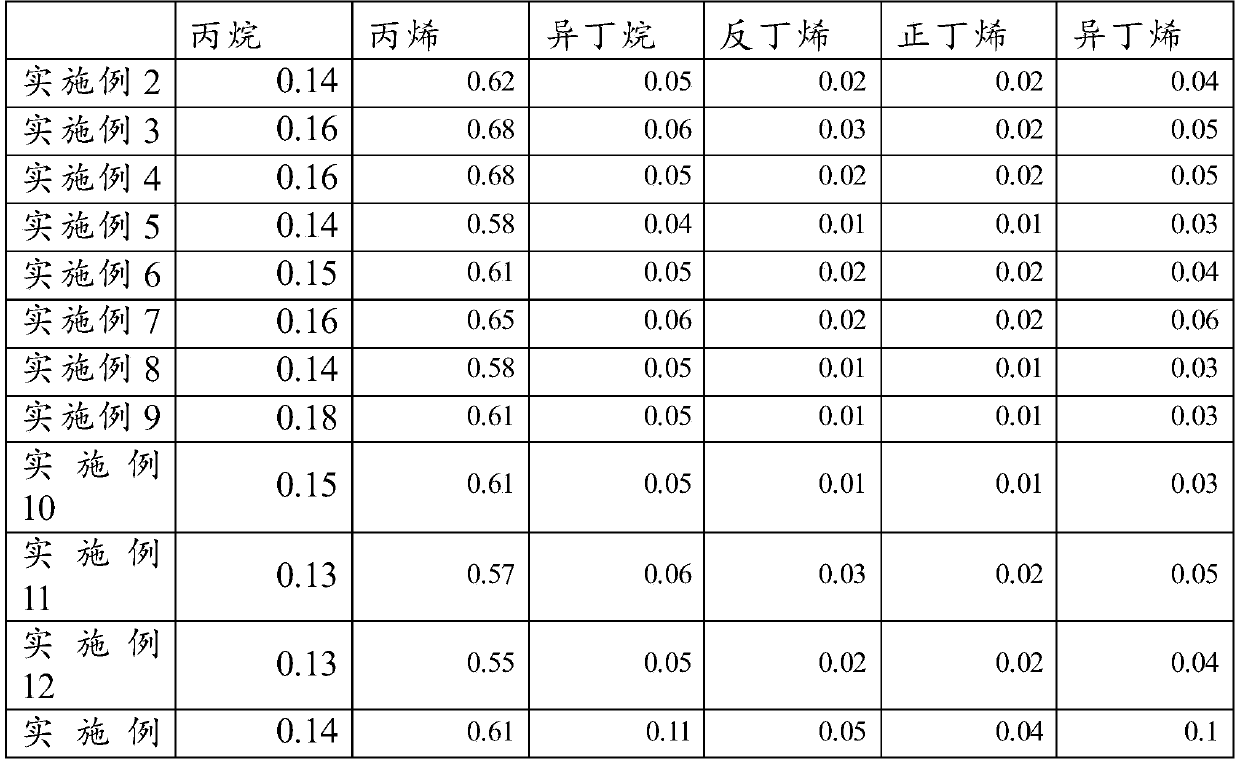

[0087] For the catalytic dry gas in the embodiment of the present invention 2 and the components in the purified dry gas are measured, the results are as shown in Table 1 and Table 2, Table 1 is the component content table in the catalytic dry gas of the embodiment of the present invention 2, table 2 is the content table of purified dry gas components.

[0088] Component content table in the catalytic dry gas of the embodiment of the present invention and comparative example of table 1

[0089]

[0090]

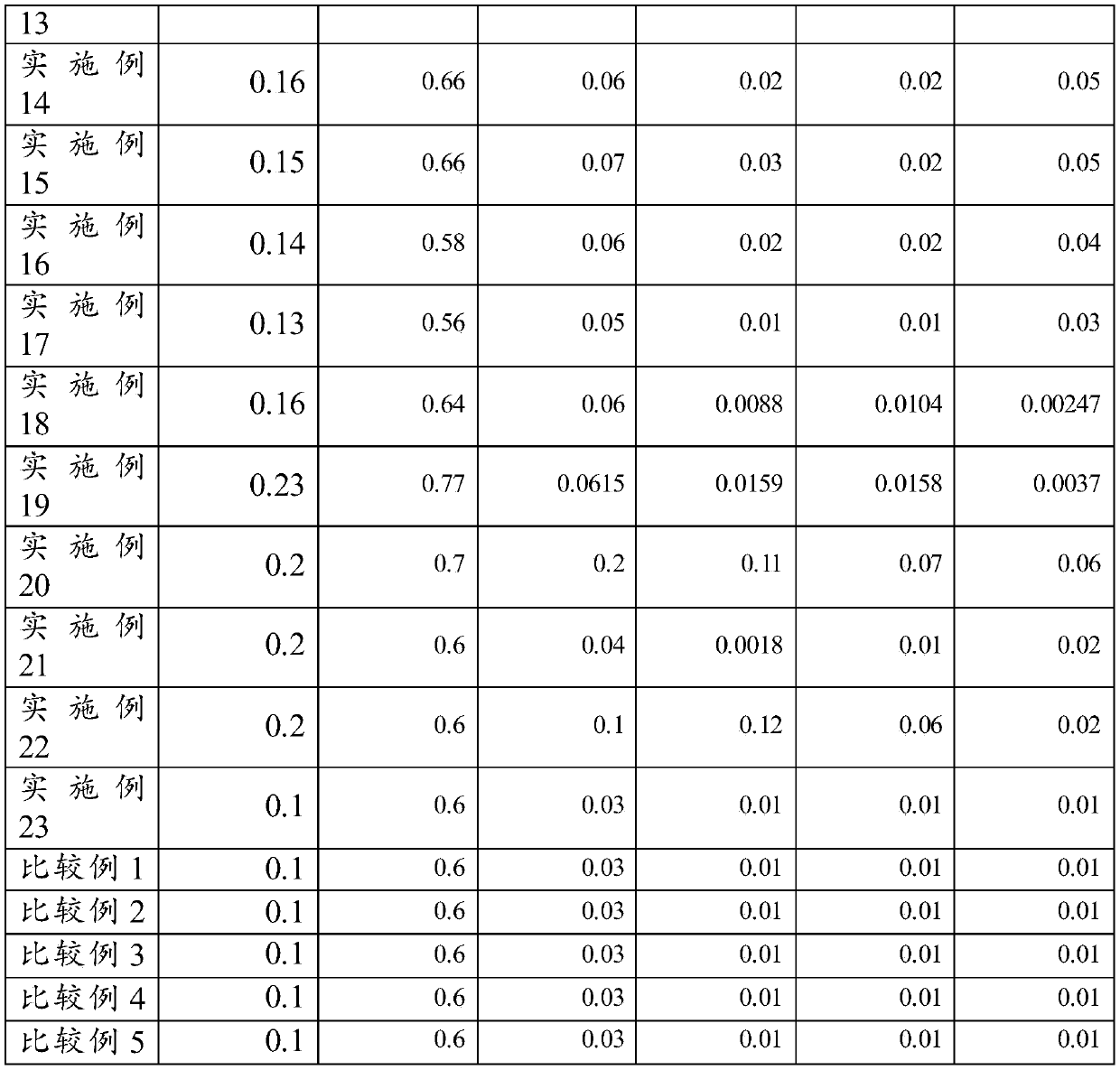

[0091] The clean dry gas component content table of the embodiment of the present invention and comparative example of table 2

[0092]

[0093]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com