2,4,6-diethyl triphosphate hydroxymethylphenoxy-1,3,5-triazine flame retardant and preparation method

A technology of diethyl triphosphate hydroxymethylphenoxy and trialdehyde phenoxy, which is applied in the field of flame retardancy, can solve the problems of deteriorating the basic physical properties of materials, affecting the durability of material flame retardancy, and uneven dispersion, achieving Strong practicability, high thermal stability, simple and easy-to-operate preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

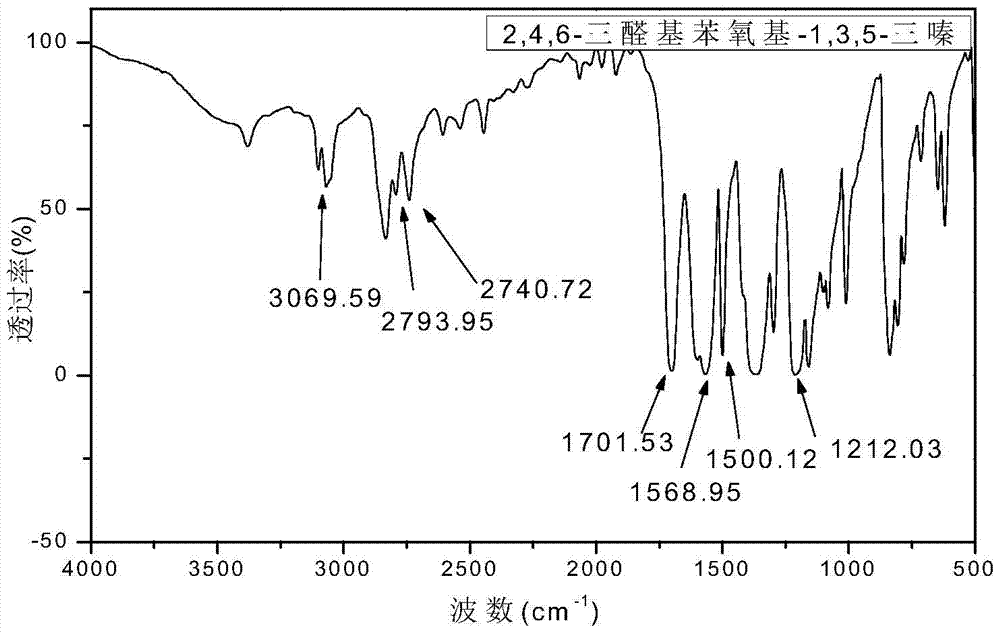

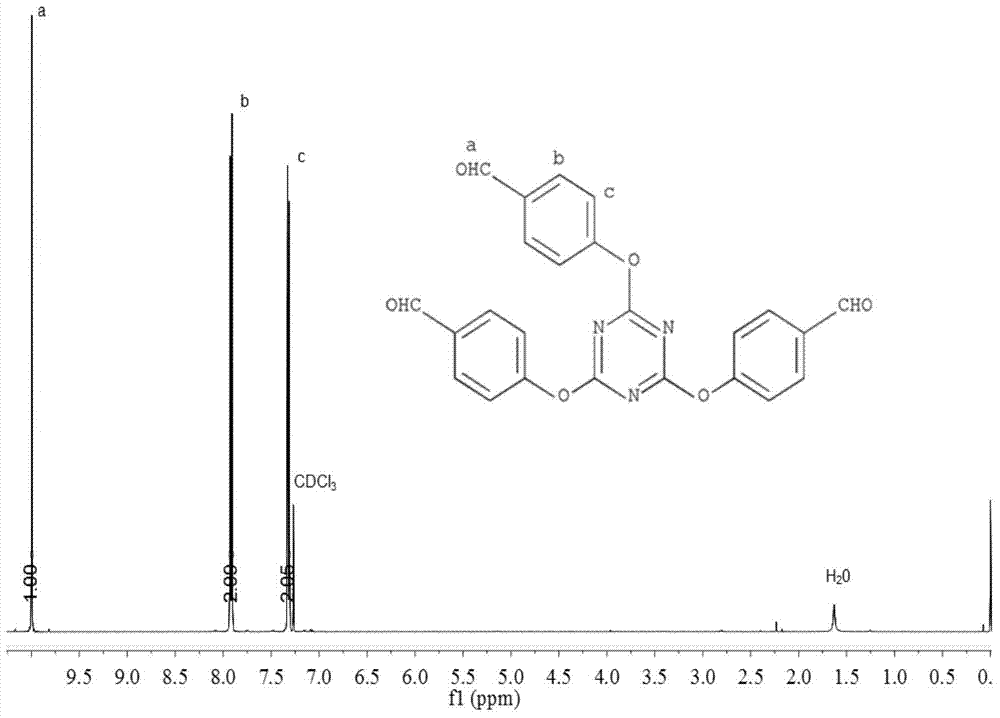

Embodiment 1

[0027] In a 500mL dry three-neck flask equipped with a mechanical stirrer, a constant pressure dropping funnel and a condensing reflux device, add 31.8g of potassium carbonate, 36.6g of p-hydroxybenzaldehyde and 250mL of refined tetrahydrofuran in sequence, and stir at room temperature for 1h under nitrogen protection Make it dissolve; Then take by weighing 18.45g cyanuric chloride (the molar ratio of cyanuric chloride and p-Hydroxybenzaldehyde is 1:3) and dissolve in 100mL refined tetrahydrofuran, slowly add it dropwise in the above-mentioned reaction system, Adding time is 1h; after 0.5h, slowly heat up to 60°C, reflux and stir for 24h, after the reaction is completed, change it to a distillation device, distill off the solvent under reduced pressure, pour it into a large amount of deionized water, and immediately precipitate a white precipitate; again Filter and wash the product repeatedly with deionized water for 3 times; vacuum-dry at 50°C for 12 hours to obtain a white po...

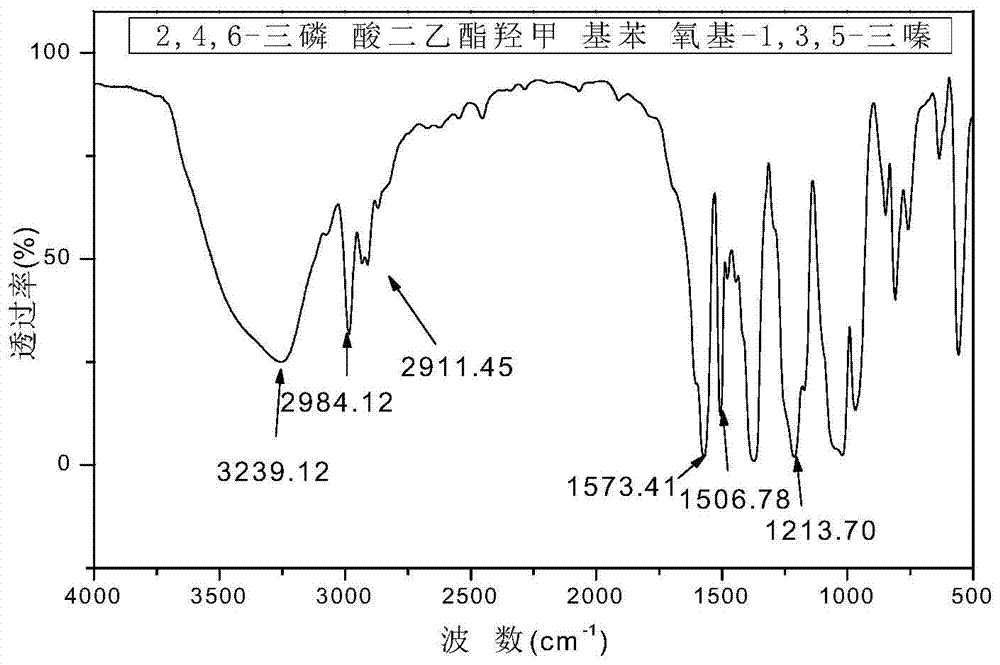

Embodiment 2

[0030] In a 500mL dry three-neck flask equipped with a mechanical stirrer, a constant pressure dropping funnel and a condensing reflux device, add 31.8g of potassium carbonate, 36.6g of p-hydroxybenzaldehyde and 250mL of refined tetrahydrofuran in sequence, and stir at room temperature for 1h under nitrogen protection Make it dissolve; Then take by weighing 18.45g cyanuric chloride (the molar ratio of cyanuric chloride and p-Hydroxybenzaldehyde is 1:4) and dissolve in 100mL refined tetrahydrofuran, slowly add it dropwise in the above-mentioned reaction system, Adding time is 1h; after 0.5h, slowly heat up to 60°C, reflux and stir for 24h, after the reaction is completed, change it to a distillation device, distill off the solvent under reduced pressure, pour it into a large amount of deionized water, and immediately precipitate a white precipitate; again Filter and wash the product repeatedly with deionized water for 3 times; vacuum-dry at 50°C for 12 hours to obtain a white po...

Embodiment 3

[0033] In a 500mL dry three-neck flask equipped with a mechanical stirrer, a constant pressure dropping funnel and a condensing reflux device, add 31.8g of potassium carbonate, 36.6g of p-hydroxybenzaldehyde and 250mL of refined tetrahydrofuran in sequence, and stir at room temperature for 1h under nitrogen protection Make it dissolve; Then take by weighing 18.45g cyanuric chloride (the molar ratio of cyanuric chloride and p-Hydroxybenzaldehyde is 1:3) and dissolve in 100mL refined tetrahydrofuran, slowly add it dropwise in the above-mentioned reaction system, Adding time is 1h; after 0.5h, slowly raise the temperature to 80°C, reflux and stir for 24h, after the reaction is completed, change it to a distillation device, distill off the solvent under reduced pressure, pour it into a large amount of deionized water, and immediately precipitate a white precipitate; again Filter and wash the product repeatedly with deionized water for 3 times; vacuum-dry at 50°C for 12 hours to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com