Method for preparing catalyst for compounding p-diethylbenzene by alkylation reaction of ethylbenzene and ethane or alcohol

A diethylbenzene catalyst, ethanol alkyl technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low utilization rate of ethanol, high energy consumption for preparation, unfavorable industrialization, etc. high yield, simple preparation process and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

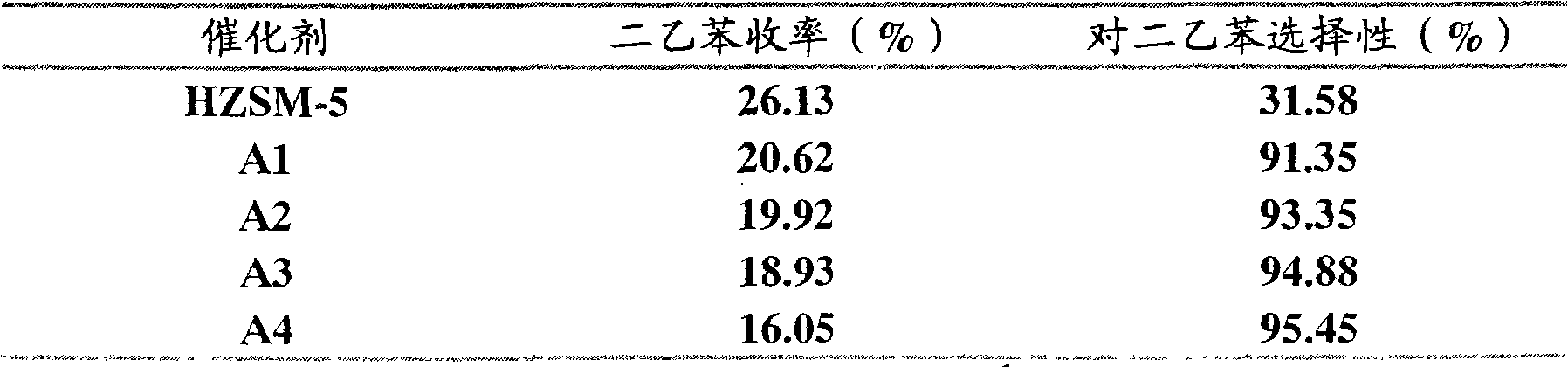

[0014] Weigh a portion of extruded, SiO 2 / Al 2 o 3 Mole ratio = 55 HZSM-5 molecular sieve, add 1.6 parts by mass of cyclohexane solution containing ethyl orthosilicate, so that the silicon dioxide obtained after the decomposition of ethyl orthosilicate accounts for 5% to 30% of the mass of the catalyst, at room temperature After stirring and impregnating for 12 hours, cyclohexane was recovered by distillation and the catalyst was dried; then, air and water vapor were passed through at 650°C for 3 hours to passivate, and the air volume space velocity was controlled to 3000h -1 , water vapor volume space velocity 65h -1 , to prepare catalysts A1-A4.

[0015] The obtained catalyst is used in the alkylation reaction of ethylbenzene and ethylene (or ethanol), and the reaction conditions are as follows: normal pressure reaction, temperature 360-380°C, total space velocity of raw material liquid mass 3-7h -1 , The molar ratio of ethylbenzene to ethylene (or ethanol) is 2:1 to 6:...

Embodiment 5

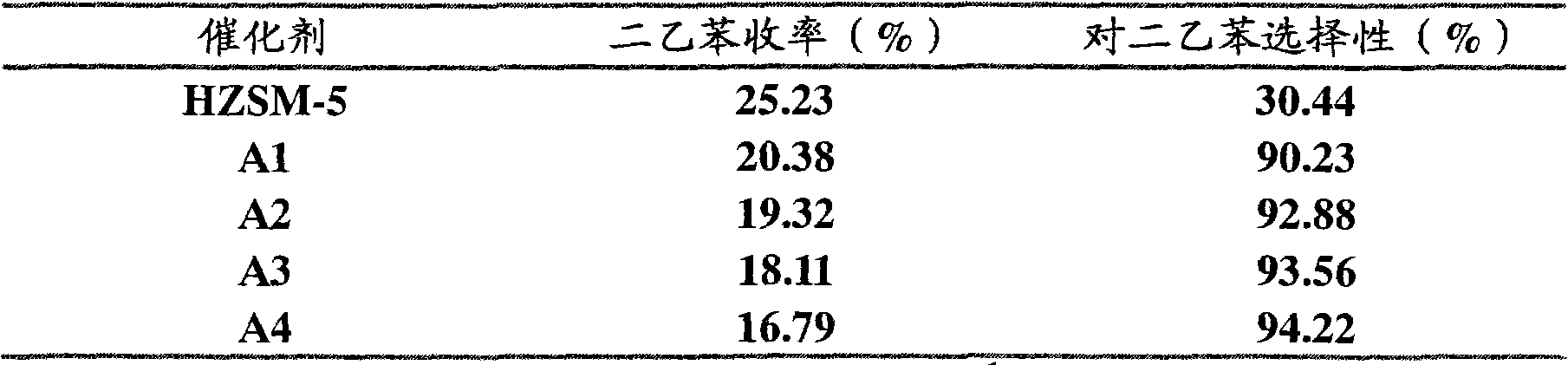

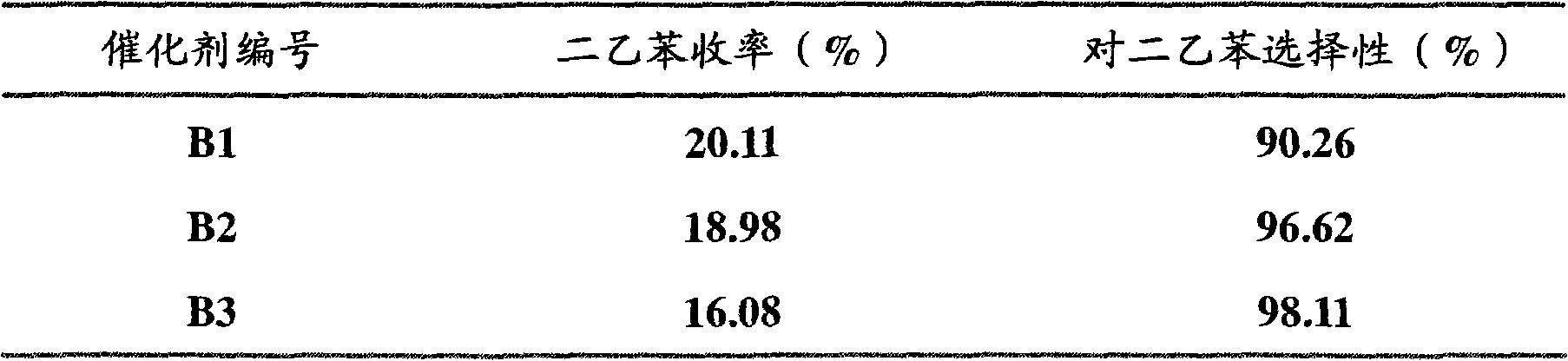

[0023] The calcination passivation temperature of Example 2 was adjusted to 650, 700 and 750° C., and the obtained catalysts were named B1, B2 and B3 in sequence. The reaction results are shown in Table 3.

[0024] Table 3 Effects of different roasting and passivation conditions on the performance of ethylphenylethanol alkylation

[0025]

[0026] Reaction conditions: normal pressure, 360°C, total space velocity of raw material liquid mass 5h -1 , ethylbenzene / ethanol molar ratio 4:1, reacted for 1 hour.

Embodiment 6

[0028] The optimized catalyst B2 was obtained through the above examples, and the results of the alkylation reaction of ethylbenzene and ethylene using it as the catalyst are shown in Table 4; the catalytic performance of the alkylation reaction of ethylbenzene and ethanol is shown in Table 5.

[0029] Table 4 Ethylbenzene and ethylene alkylation reaction performance of B2 catalyst

[0030]

[0031]

[0032] Reaction conditions: normal pressure, total space velocity of raw material liquid mass 5h -1 , ethylbenzene / ethylene molar ratio 4.4:1.

[0033] Table 5 Ethylbenzene and ethanol alkylation reaction performance of B2 catalyst

[0034]

[0035] Reaction conditions: normal pressure, total space velocity of raw material liquid mass 5h -1 , ethylbenzene / ethanol molar ratio 4.4:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com