Preparation method and application of molecular sieve catalyst containing aluminum phosphate binder

A molecular sieve and binder technology, which is applied in the field of molecular sieve catalyst preparation, can solve problems such as research that has not yet been reported, and achieve the effects of improving conversion rate and good anti-carbon performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

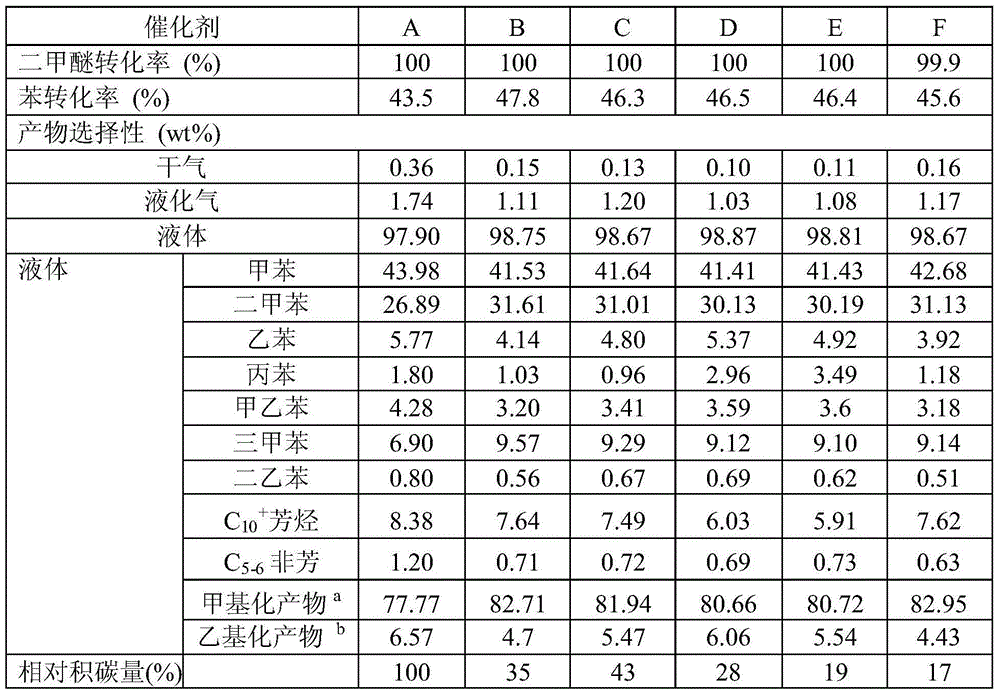

Embodiment 1

[0030] A certain amount of rare earth ZSM-11 molecular sieve with a particle size of 350nm (the rare earth content accounts for 1.2wt% of the rare earth ZSM-11 molecular sieve) was roasted at 550°C for 4h to burn off the template agent, and then used 0.8mol / L ammonium nitrate at 80°C The solution was exchanged three times, washed twice, dried at 120°C, and calcined at 540°C for 3 hours to obtain H-type molecular sieves. Zn load 5wt%; phosphoric acid solution and boehmite according to P / Al molar ratio (the molar ratio of P element in phosphoric acid solution to Al element in boehmite, the same below) is 0.8 and stirred evenly, add to the preparation in the previous step For a good molecular sieve catalyst, the weight ratio of molecular sieve dry basis to boehmite dry basis is 4, stir evenly, dry at 125°C, and then calcinate at 580°C for 6 hours. The obtained catalyst is designated as B.

Embodiment 2

[0032] A certain amount of rare earth ZSM-11 molecular sieve with a particle size of 500nm (rare earth content accounts for 2.3wt% of the rare earth ZSM-11 molecular sieve) was roasted at 500°C for 3 hours to burn off the template agent, and then used 0.6mol / L ammonium nitrate at 70°C The solution was exchanged 3 times, washed 2 times with water, dried at 120°C, calcined at 500°C for 4 hours to obtain H-type molecular sieve, and then conventionally impregnated with zinc metal, using zinc acetate solution, dried at 90°C for 1.5 hours, and calcined at 500°C for 5 hours. The Zn loading of the catalyst is 1.2wt%; the phosphoric acid solution and boehmite are stirred evenly according to the P / Al molar ratio of 0.5, and the molecular sieve catalyst prepared in the previous step is added. , After drying at 145°C, it was calcined at 500°C for 7h, and the obtained catalyst was designated as C.

Embodiment 3

[0034] A certain amount of rare earth ZSM-11 molecular sieve with a particle size of 900nm (rare earth content accounts for 2.5wt% of the rare earth ZSM-11 molecular sieve) was roasted at 550°C for 4 hours to burn off the template agent, and then heated with 0.7mol / L nitric acid at 60°C The ammonium solution was exchanged 3 times, washed 2 times with water, dried at 120°C, and calcined at 550°C for 4 hours to obtain H-type molecular sieves, and then routinely impregnated with zinc metal, using zinc nitrate solution, dried at 80°C for 3 hours, and calcined at 550°C for 6 hours. Catalyst Zn loading 4wt%; phosphoric acid solution and boehmite are stirred evenly according to the P / Al molar ratio of 0.2, and the molecular sieve catalyst prepared in the previous step is added. After drying at 150°C, it was calcined at 650°C for 6 hours, and the obtained catalyst was designated as D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com