Method for utilizing circulating fluidized bed to prepare propylene and C4 hydrocarbons from methanol

A circulating fluidized bed and methanol preparation technology, which is applied in the field of chemical catalysis, can solve the problems of easy coking and deactivation of the catalyst, slow heat dissipation of the fixed bed, etc., and achieve the effects of good economy, wide operating conditions and increased space velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

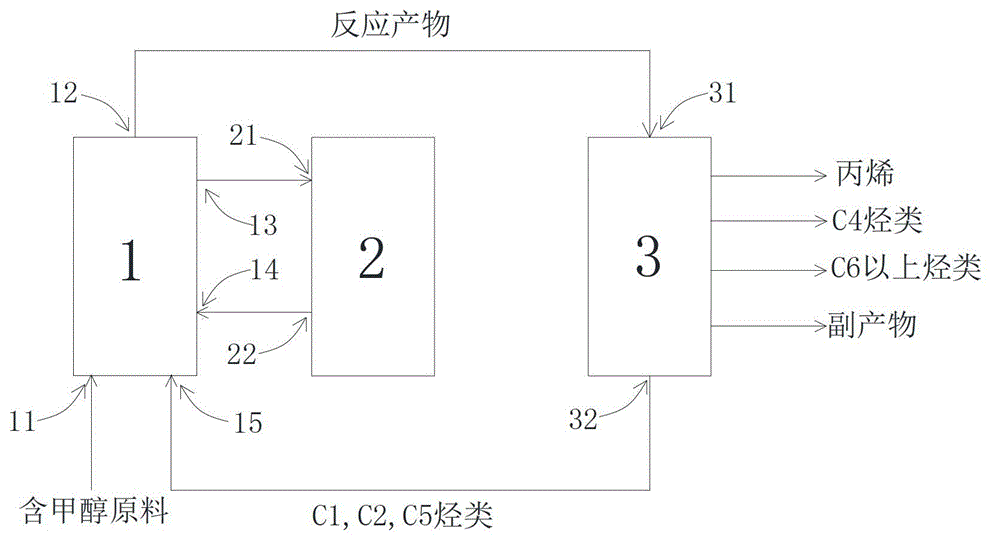

Image

Examples

Embodiment 1

[0054] The 120Kg catalyst prepared according to No. 201310040880.0 Chinese patent application (using ZSM-5 molecular sieve with a silicon-aluminum ratio of 200 as the active ingredient, the mass content of ZSM-5 molecular sieve in the catalyst is 50%, and the average particle size of catalyst microspheres is 85 μm) is loaded In a circulating fluidized bed reactor with a reactor inner diameter of 263mm and a height of 1288mm, the raw material methanol is gasified at a gasification temperature of 300°C, then passed into the fluidized bed reactor, and reacted under the action of the above catalyst, The mass space velocity of methanol is 4h -1 , the linear velocity of which enters the reactor is 0.3m / s, the temperature of the reactor is 500°C, and the pressure is 0.09MPa.

[0055] The reaction product from the fluidized bed reactor enters the separation system mainly composed of water washing tower, alkali washing tower, deethanizer and other rectification towers, and C1, C2, and ...

Embodiment 2

[0059]150kg of catalyst prepared according to Chinese patent application No. 201310040880.0 (ZSM-5 molecular sieve with a silicon-aluminum ratio of 200 as the active ingredient, the mass content of ZSM-5 molecular sieve in the catalyst is 20%, and the average particle size of the catalyst microspheres is 60 μm) is loaded In a circulating fluidized bed reactor with an inner diameter of 263mm and a height of 1288mm, the raw material methanol aqueous solution (alcohol-water ratio is 10) is gasified at a gasification temperature of 300°C, and then passed into the fluidized bed reactor In the reaction under the action of the above catalyst, the mass space velocity of methanol is 3h -1 , the linear velocity of which enters the reactor is 0.1m / s, the temperature of the reactor is 450°C, and the pressure is 0.15MPa.

[0060] The reaction product from the fluidized bed reactor enters the separation system mainly composed of water washing tower, alkali washing tower, deethanizer and oth...

Embodiment 3

[0064] 150 kg of the above-mentioned catalyst prepared according to the Chinese patent application No. 201310040880.0 (with the ZSM-5 molecular sieve having a silicon-aluminum ratio of 200 as the active ingredient, the mass content of the ZSM-5 molecular sieve in the catalyst being 80%, and the average particle diameter of the catalyst microspheres being 100 μm) Fill it into a circulating fluidized bed reactor with an inner diameter of 263mm and a height of 1288mm. After gasifying the raw methanol aqueous solution (alcohol-water ratio: 5) at a gasification temperature of 300°C, it is passed into the fluidized bed for reaction. In the reactor, react under the action of the above catalyst, wherein the mass space velocity of methanol is 8h -1 , the linear velocity of which enters the reactor is 1m / s, the temperature of the reactor is 490°C, and the pressure is 0.1MPa.

[0065] The reaction product from the fluidized bed reactor enters the separation system mainly composed of wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com