Hollow fiber membrane reactor for gaseous oxidation reaction, preparation and application thereof

A technology of fiber membrane reactor and gas-phase oxidation, which is applied in chemical methods, chemical instruments and methods, and membrane technology for reacting liquid and gas media, and can solve the problems of high price and limited industrialization and application of membrane reactors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

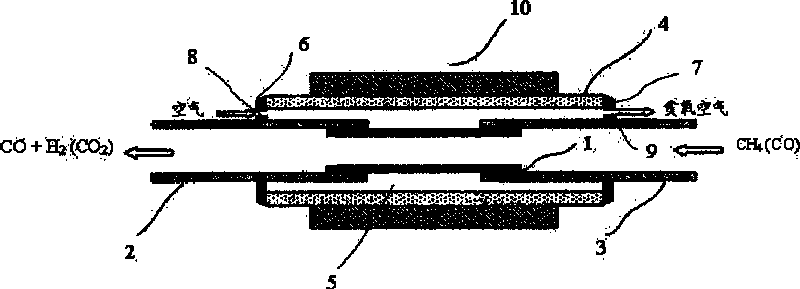

[0055] Fabrication and Application of Hollow Fiber Membrane Reactor for CO Combustion

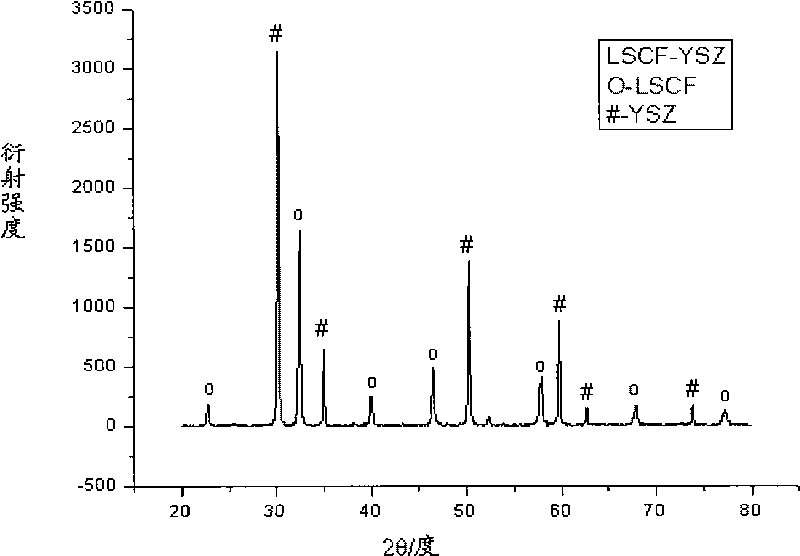

[0056] First follow La 0.8 Sr 0.2 Cr 0.5 Fe 0.5 o 3 The stoichiometric ratio of (LSCF) accurately weighed SrCO 3 , La 2 o 3 and Cr 2 o 3 and Mn 2 o 3 , after mixing the raw materials, use ethanol as the medium to ball mill for 24 hours; after drying, sinter and react at 1200°C for 10 hours to obtain the LSCF product in the pure perovskite phase, and pulverize to obtain the electronically conductive phase powder. The ion-conducting phase adopts commercial fluorite-type Zr 0.84 Y 0.16 o 1.92 (YSZ) powder.

[0057] The above-mentioned LSCF and YSZ powders were mixed according to the volume ratio of 40:60, and mixed uniformly by ball milling in ethanol for 24 hours. Powder raw material.

[0058] Mix 0.86% polyvinylpyrrolidone, 3.46% polyethersulfone, 19.68% N-methyl-1-pyrrolidone and 76% LSCF / YSZ mixed powder and ball mill for 48 hours to obtain a uniform slurry , and the resul...

Embodiment 2

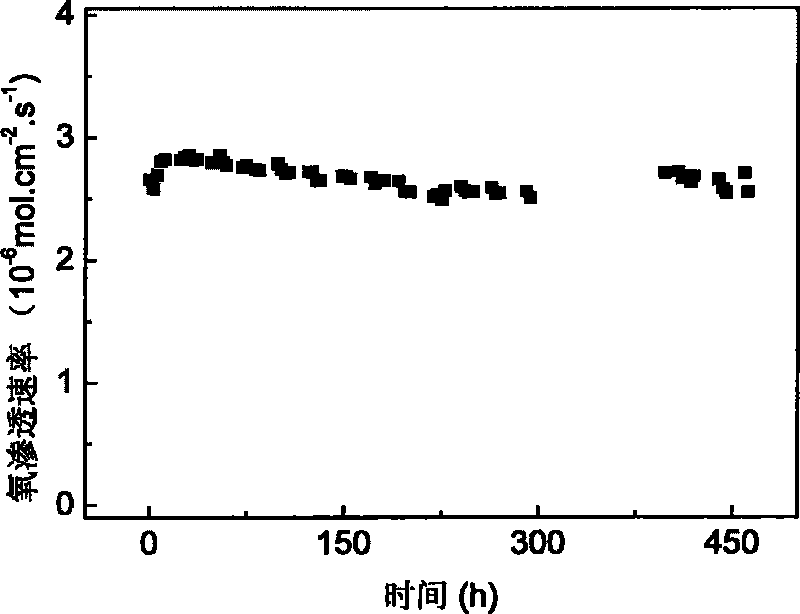

[0062] Preparation and Application of Hollow Fiber Membrane Reactor for Partial Oxidation of Methane

[0063] The hollow fiber membrane reactor used for the partial oxidation of methane needs to attach a catalyst coating to the wall of its oxygen permeable membrane. This embodiment takes the preparation of the LSCF / YSZ hollow fiber membrane reactor with a Ni-based catalyst coating on the inner wall as an example to illustrate the preparation and application of this type of reactor in the present invention. The specific implementation steps are as follows:

[0064] Mix 0.2% polyvinylpyrrolidone, 5.18% polyethersulfone, 42.62% N-methyl-1-pyrrolidone and 52% of the LSCF / YSZ mixed powder in Example 1 and ball mill for 48 hours , to obtain a homogeneous slurry, the resulting slurry was vacuum degassed for two hours. Then adopt the spinneret that the interlayer gap that is formed by two concentric circular tubes inside and outside is 1.0mm, inner pipe hole diameter is the spinnere...

Embodiment 3

[0071] Preparation and Application of Hollow Fiber Membrane Reactor for Methane Combustion

[0072] In this example, Sr 0.3 Ba 0.5 La 0.2 MnAl 11 o 19 The catalyst-coated LSCF / YSZ hollow fiber membrane reactor is taken as an example to specifically illustrate the preparation and application of this type of reactor in the present invention.

[0073] Mix 0.5% polyvinylpyrrolidone, 5.92% polyethersulfone, 33.58% N-methyl-1-pyrrolidone and 60% of the LSCF / YSZ mixed powder in Example 1 and ball mill for 48 hours , to obtain a homogeneous slurry, the resulting slurry was vacuum degassed for two hours. Then adopt the spinneret that the interlayer gap that is formed by two concentric circular tubes inside and outside is 1.0mm, inner pipe hole diameter is 2.0mm as the extrusion die, make the slurry pass through the interlayer gap of the spinneret under 0.03MPa pressure, at the same time Under the pressure of 0.01MPa, tap water at a temperature of 25°C is extruded from the inner t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com