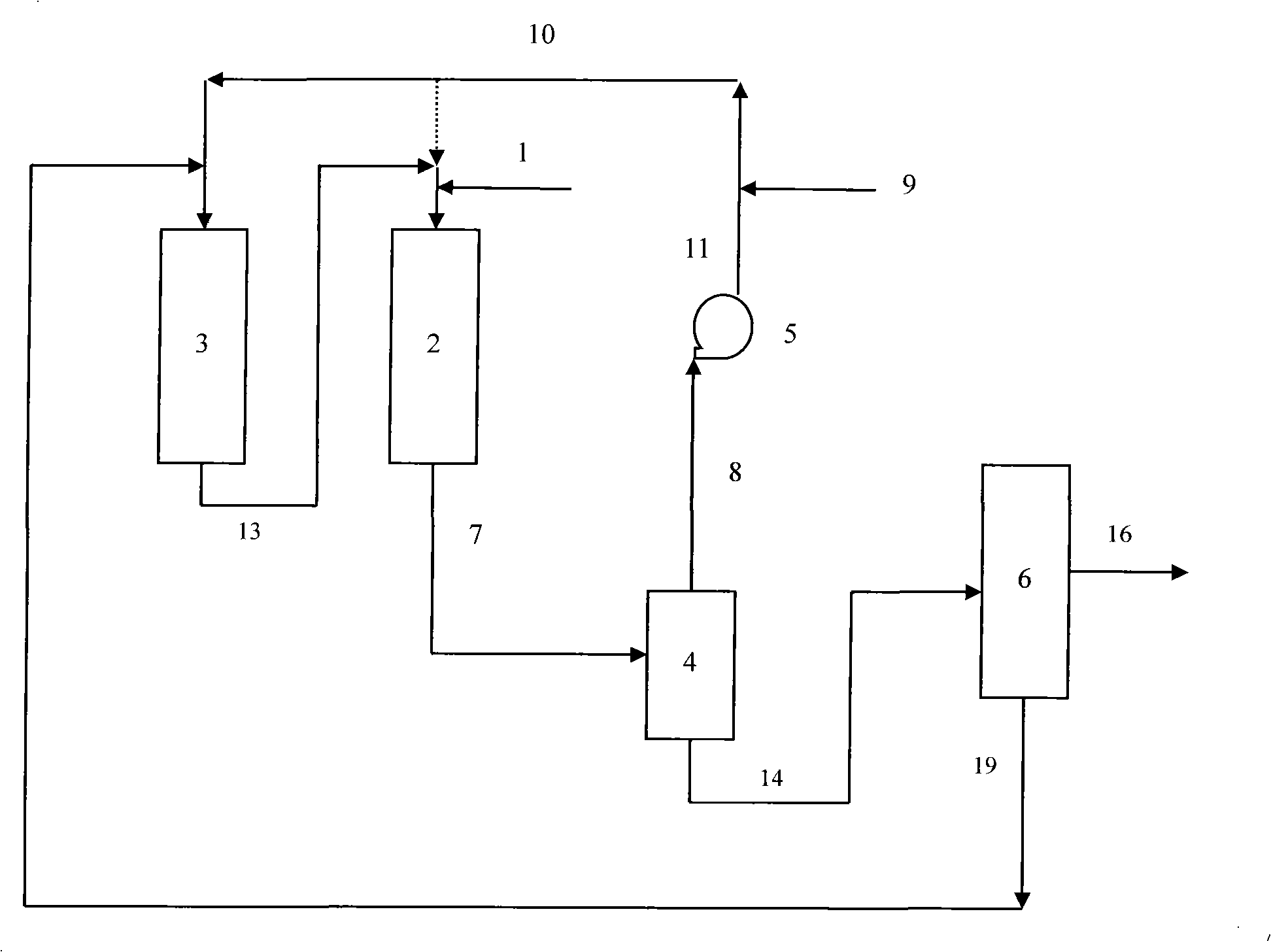

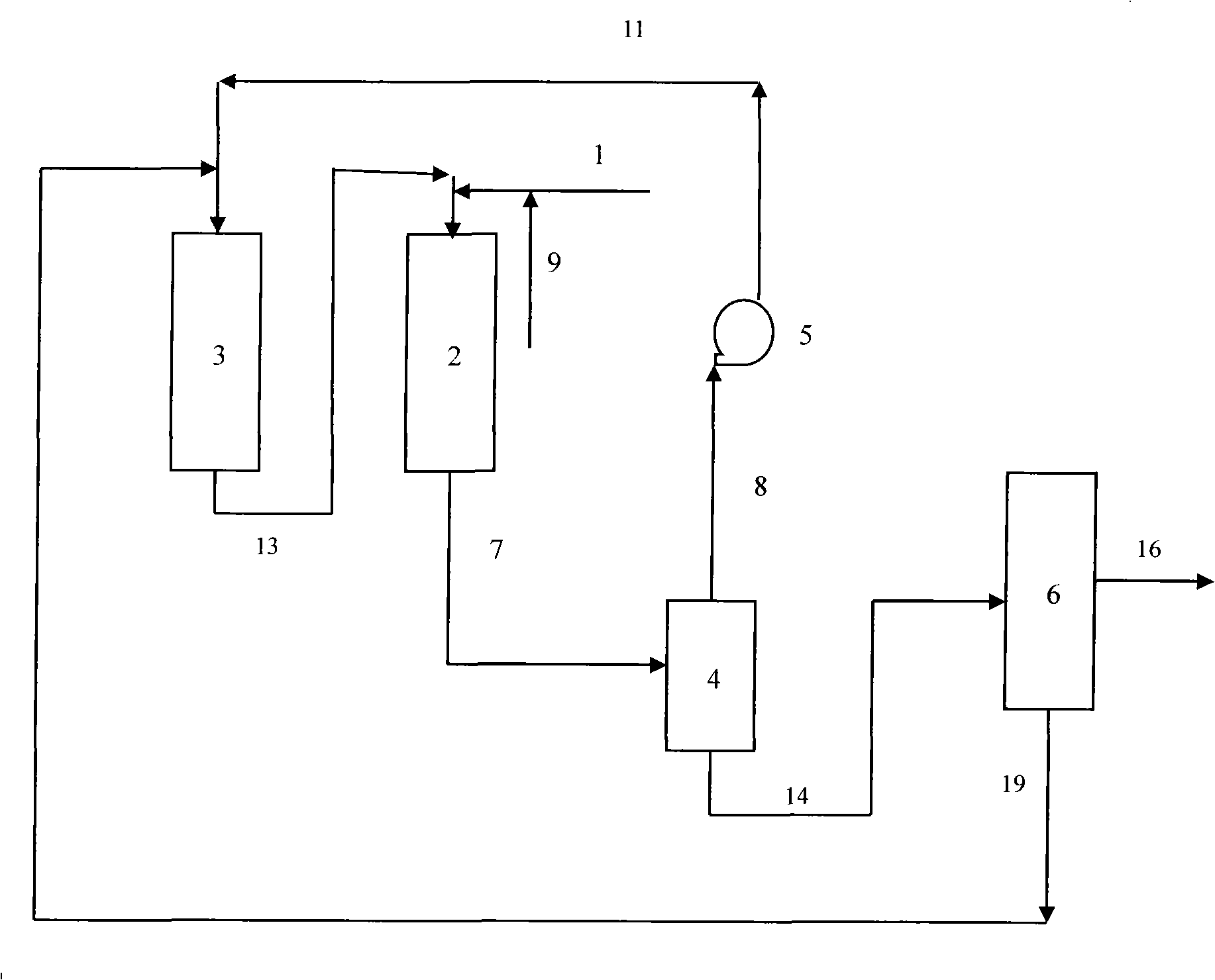

Hydrogenation conversion process

A technology of hydroconversion and hydrocracking, which is applied in the fields of hydroprocessing, petroleum industry, and hydrocarbon oil treatment, etc., to achieve the effects of saving equipment investment and operating costs, increasing space velocity, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1

[0031] The used raw material properties of embodiments and comparative examples are shown in Table 1, and the test process conditions and the product properties obtained are listed in Table 2 and Table 3.

[0032] Table 1 Raw Oil Properties

[0033] Raw oil

[0034] *Mixed oil is as follows, by weight: coking whole distillate oil: ordinary third line oil: minus first line oil = 30:40:30

[0035] Table 2 process conditions and product properties

[0036] Example 1

[0037] Table 3 Product Properties

[0038] Example 1

[0039] It can be seen from the data of the examples and comparative examples that, through the hydrogenation combined process of the present invention, the operating severity of the device can be reduced, the processing capacity of the device can be increased, and high-quality light fuel products can be produced at the same time, especially the direct production of fuel products that meet the specifications High quality naphth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com