Solder paste scaling powder

A flux and solder paste technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of high corrosion, affecting the long-term stability of the pad, high rosin residue, etc., to achieve low corrosion, The effect of less residue and stable properties of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

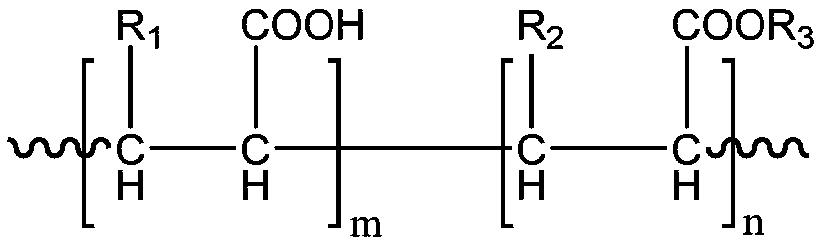

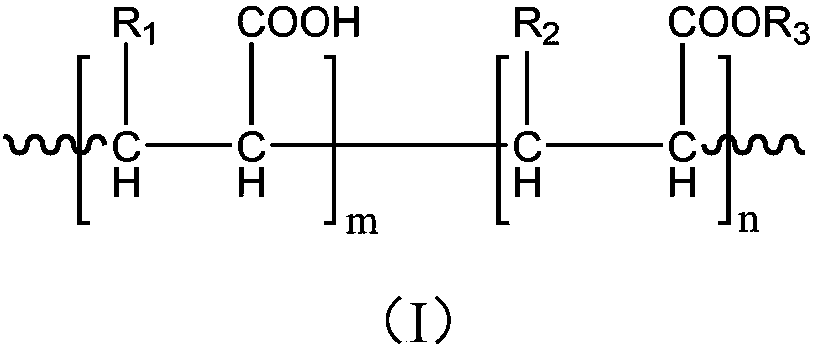

[0034] An embodiment of the solder paste flux described in the present invention, the solder paste flux described in this embodiment comprises the following components in percentage by weight: film forming agent 30%, active agent 5%, solvent 59%, thickener 3% agent, 1% corrosion inhibitor, 1% antioxidant and 1% pH regulator;

[0035] Among them, R 1 is methyl, R 2 is ether group, R 3 is a dimethyl sulfoxide group; m is 1, n is 1; the molecular weight of the acrylic resin is 306.

[0036] The film forming agent is a mixture of acrylic resin, hydrogenated rosin and polymerized rosin; the weight percentage of the acrylic resin in the solder paste flux is 20%; the active agent is succinic acid, sebacic acid and maleic acid The thickener is hydrogenated castor oil wax; the corrosion inhibitor is oleic acid imidazoline, the antioxidant is hydroquinone; the pH regulator is triethanolamine; the solvent is diethylene glycol dibutyl ether and tetraethylene glycol Alcohol dimethyl et...

Embodiment 2

[0039] An embodiment of the solder paste flux described in the present invention, the solder paste flux described in this embodiment comprises the following components in percentage by weight: 50% film-forming agent, 15% active agent, 5% thickener, Corrosion inhibitor 2%, antioxidant 2%, pH regulator 2% and solvent 24%;

[0040] Among them, R 1 is n-decyl ether group, R 2 is n-decyl ether group; R 3 is n-decyl ether group; m is 290, n is 290; the molecular weight of the acrylic resin is 299280.

[0041] The film-forming agent is a mixture of acrylic resin, ice white rosin and modified rosin; the weight percentage of the acrylic resin in the solder paste flux is 30%; the active agent is malonic acid, phenylimidazole and horseradish The mixture of acid; the thickener is polyamide wax; the corrosion inhibitor is benzotriazole; the antioxidant is 2,6-di-tert-butyl p-cresol; the pH regulator is diethanolamine; the solvent is diethyl A mixture of glycol monobutyl ether and dieth...

Embodiment 3

[0044] An embodiment of the solder paste flux described in the present invention, the solder paste flux described in this embodiment comprises the following components in weight percentage: 40% film forming agent, 10% active agent, 5% thickener, Corrosion inhibitor 2%, antioxidant 2%, pH regulator 1%, solvent 40%;

[0045] Among them, R 1 is phenyl, R 2 is n-hexyl, R 3 is hydroxyethyl; m is 300, n is 300; the molecular weight of the acrylic resin is 122400.

[0046] The film forming agent is a mixture of acrylic resin, disproportionated rosin and acrylic rosin; the weight percentage of the acrylic resin in the solder paste flux is 30%; the active agent is azelaic acid, phenylimidazole and diethanolamine The mixture; the thickener is polyamide wax; the corrosion inhibitor is hydroxyglyceride; the antioxidant is resorcinol; the pH regulator is ethanolamine; the solvent is a mixture of diethylene glycol monohexyl ether and tetrahydroconol.

[0047] A solder paste containing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com