End hose of cantilever crane system, preparation method thereof and concrete transporting machine

A technology of end hoses and booms, which is applied in the field of concrete conveying machinery, can solve the problems of affecting the operation of the output port of the end hose, increasing the end hose, and the weight of the end hose, etc., so as to improve the material conveying efficiency and reduce the Clogging phenomenon, the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not limit the protection scope of the present invention in any way.

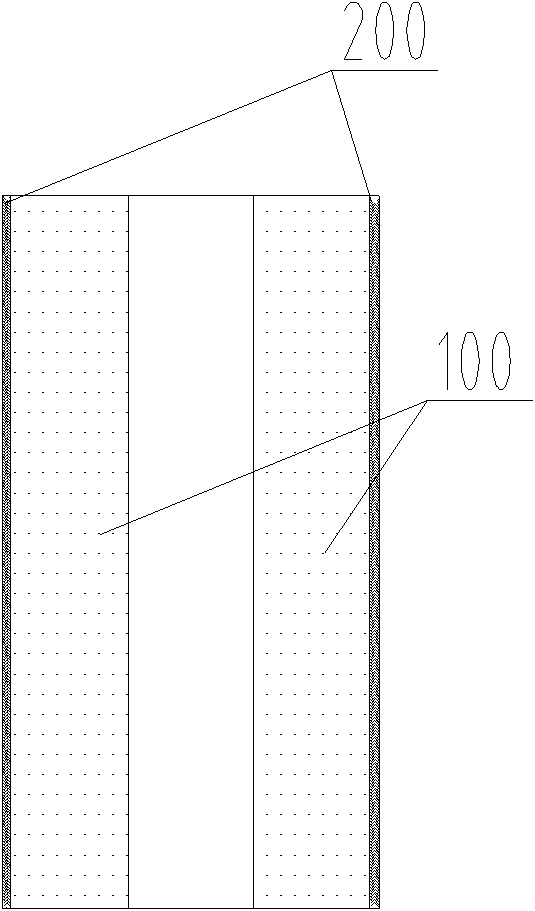

[0040] Please refer to figure 1 , which is a schematic structural view of the terminal hose of a boom system provided by the present invention.

[0041] The terminal hose includes a pipe body 100 and a fiber reinforced layer 200; wherein the pipe body 100 is a polyurethane elastomer formed of polyurethane material; the fiber reinforced layer 200 is compounded on the outer wall of the pipe body 100, and the fiber reinforced layer 200 can be formed by glass fibers , can also be formed of carbon fiber to ensure the strength of the end hose and improve the tear resistance and tensile performance of the end hose. At the same time, because the polyurethane material has strong wear resistance, fatigue resistance and vibration resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com