Multi-parameter online monitoring and optimizing control device and method of polycrystalline silicon reduction furnace

An optimized control and multi-parameter technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., to achieve high precision, large temperature measurement range, and ensure production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] When the present invention is described further below in conjunction with example and accompanying drawing, but should not limit protection scope of the present invention with this.

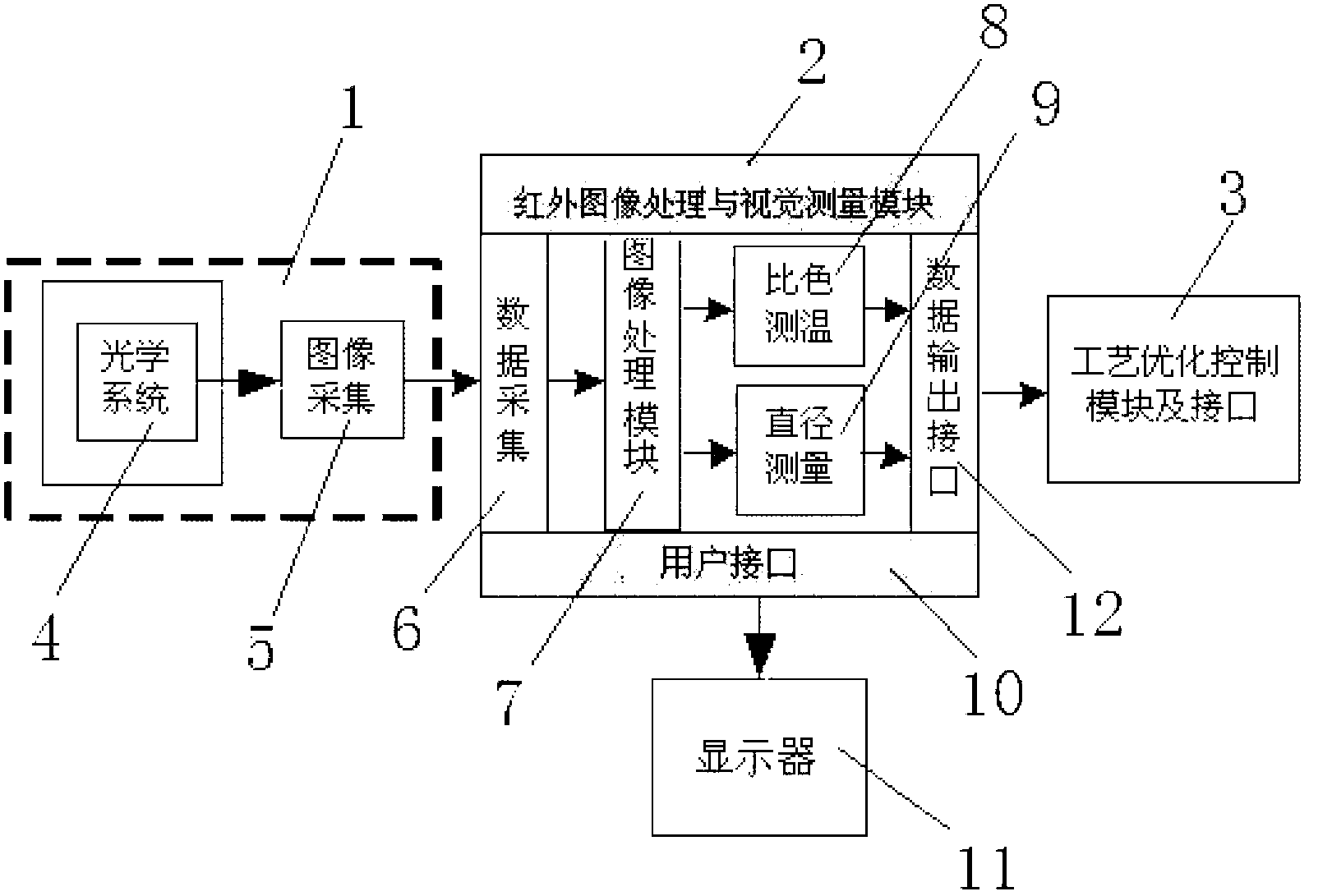

[0030] The structural composition of the present invention is as figure 1 shown.

[0031] The polysilicon reduction furnace multi-parameter online monitoring and optimization control device is characterized in that it includes a multi-parameter infrared monitoring probe 1, an infrared image processing and visual measurement module 2, and a process optimization control module 3. The multi-parameter infrared monitoring probe 1 includes a near-infrared Optical system 4, image acquisition module 5, the multi-parameter infrared monitoring probe is equipped with a water-cooled protective cover outside, and the front end of the water-cooled protective cover is equipped with a water-cooled sealed pressure-resistant observation window, and the multi-parameter infrared monitoring probe goes deep int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com