Wave-transmitting core clamping material of antenna cover and manufacturing method and application thereof

A sandwich material and wave-transmitting technology, applied in the field of materials, can solve problems such as high dielectric constant and dielectric loss, electromagnetic wave energy damage, and affecting material wave transparency, achieving low dielectric constant, reduced dielectric constant, The effect of good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

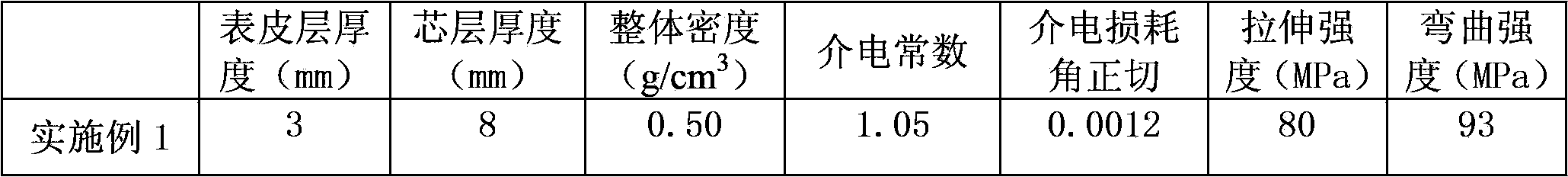

Embodiment 1

[0067] A kind of wave-transparent sandwich material, its preparation method comprises the following steps:

[0068] 1. Preparation of Epidermal Layer

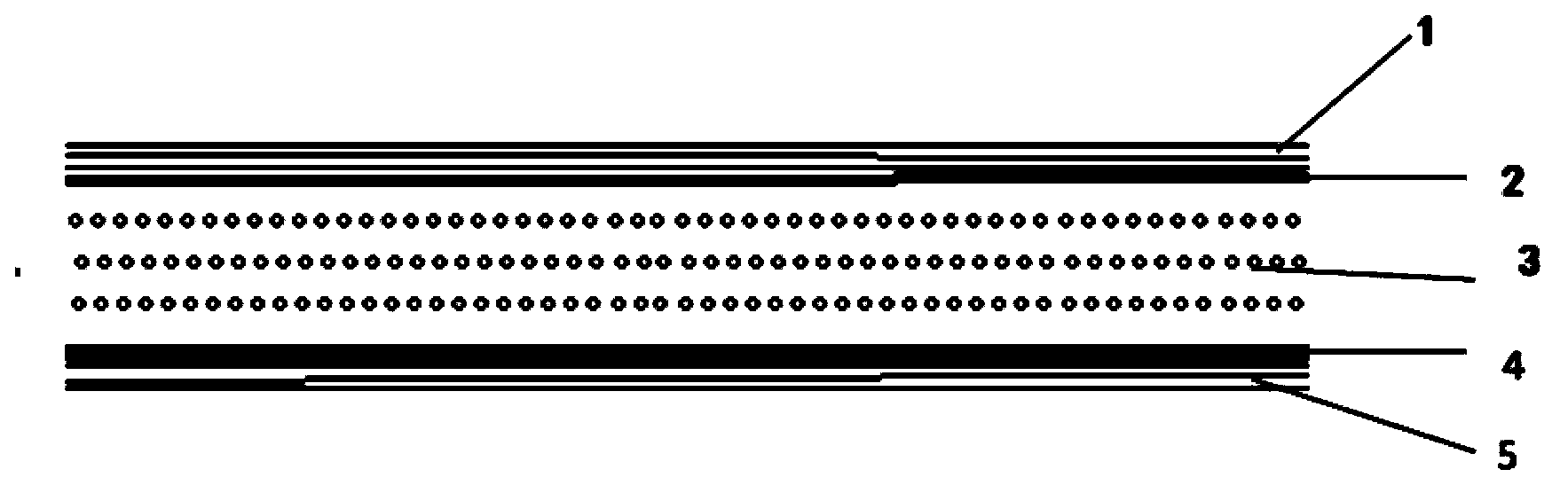

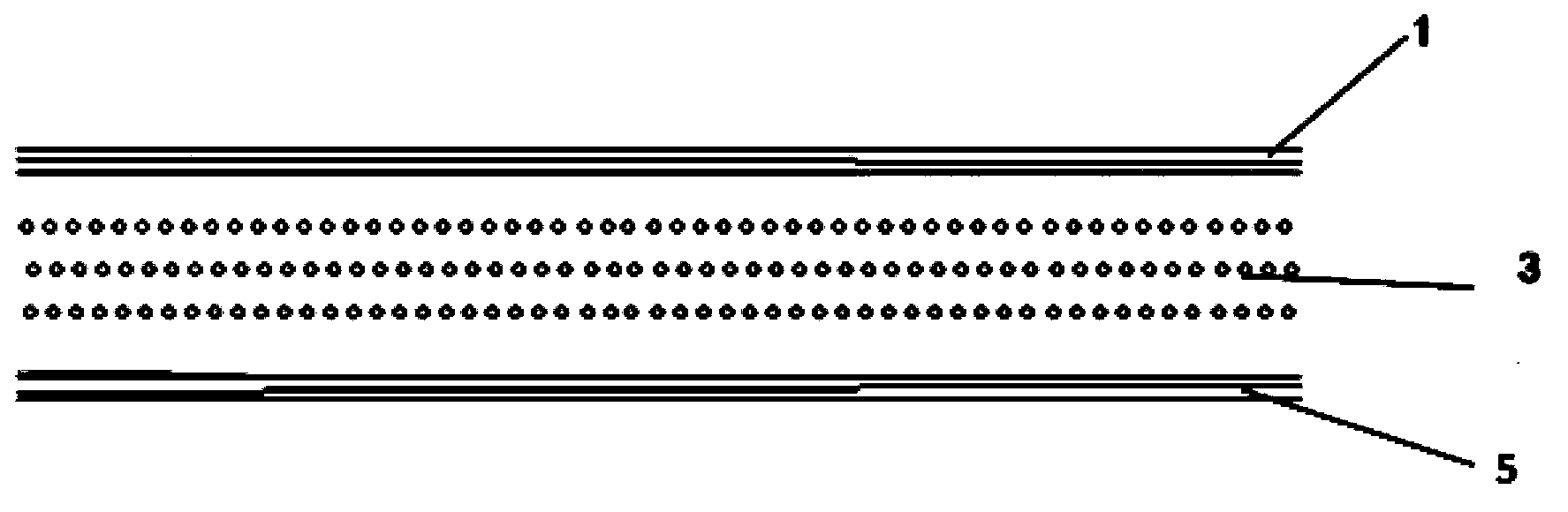

[0069] Through thermal compounding process, PET non-woven material and 3mm thick glass fiber reinforced polypropylene sheet (GMT, South Korea Hanwha Composite Materials Co., Ltd.) were composited at 190°C by rolling to obtain a composite sheet as a sandwich composite material The upper epidermis 1 and the lower epidermis 5.

[0070] 2. Preparation of foam core layer

[0071] Put the polyurethane foam material raw material into the foaming equipment, and at the same time add carbon dioxide gas through high pressure, and use microwave to disperse, so that the carbon dioxide gas can be evenly integrated into the raw material. With the reaction of the raw material, reduce the pressure to expand the carbon dioxide gas, and obtain a density of 0.5g. / cm 3 A polyurethane foam core layer with a pore diameter of 10-20 nm is used as t...

Embodiment 2

[0075] A kind of wave-transparent sandwich material, its preparation method comprises the following steps:

[0076] Weigh 68 parts by weight of thermoplastic resin and 4 parts of additives and mix them evenly, add them into the twin-screw extruder, extrude the film, and at the same time spread 35 parts of continuous fibers into continuous fiber tapes, and lead them to the extrusion process after preheating. At the die head of the machine, it is infiltrated with the molten resin extruded and coated, rolled, and cooled to obtain a continuous fiber-reinforced thermoplastic composite material as the upper skin layer and the lower skin layer of this embodiment;

[0077] Wherein the thermoplastic resin is polyurethane, the continuous fiber is glass fiber, and the additives are 2 parts of 2,6-tertiary butyl-4-methylphenol and 2 parts of bis(3,5-tertiary butyl-4-hydroxyl Phenyl) sulfide mixtures.

[0078] Put the upper and lower skin layers on both sides of the mold and fix them, res...

Embodiment 3

[0081] A kind of wave-transparent sandwich material, its preparation method comprises the following steps:

[0082] 1. Preparation of Epidermal Layer

[0083] Weigh 50 parts of thermoplastic resin, 45 parts of long fiber, and 6 parts of additives in parts by weight, mix them evenly, add them into a twin-screw extruder, extrude them into sheets, roll them, and cool them to obtain long fiber reinforced thermoplastic composites. The material is used as the upper skin layer and the lower skin layer; wherein the thermoplastic resin is nylon 66, the long fiber is glass fiber, and the auxiliary agent is 1.5 parts of antioxidant 2,6-tertiary butyl-4-methylphenol, 1.5 parts A mixture of ultraviolet absorber 2,4-dihydroxybenzophenone and 3 parts of coupling agent γ-aminopropyltriethoxysilane, the average length of long fibers is 0.6mm;

[0084] 2. Preparation of foam core layer

[0085] The foam core layer is made of polyurethane foam board from Jiangsu Luyuan New Material Co., Ltd., ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com