Waste tire rubber powder plant asphalt material and preparation method thereof

A technology of waste tire rubber powder and plant asphalt, which is applied in building thermal insulation materials, building structures, building components, etc., can solve problems such as shortage of petroleum asphalt, and achieve the effects of alleviating increasing tension, reducing construction costs, and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

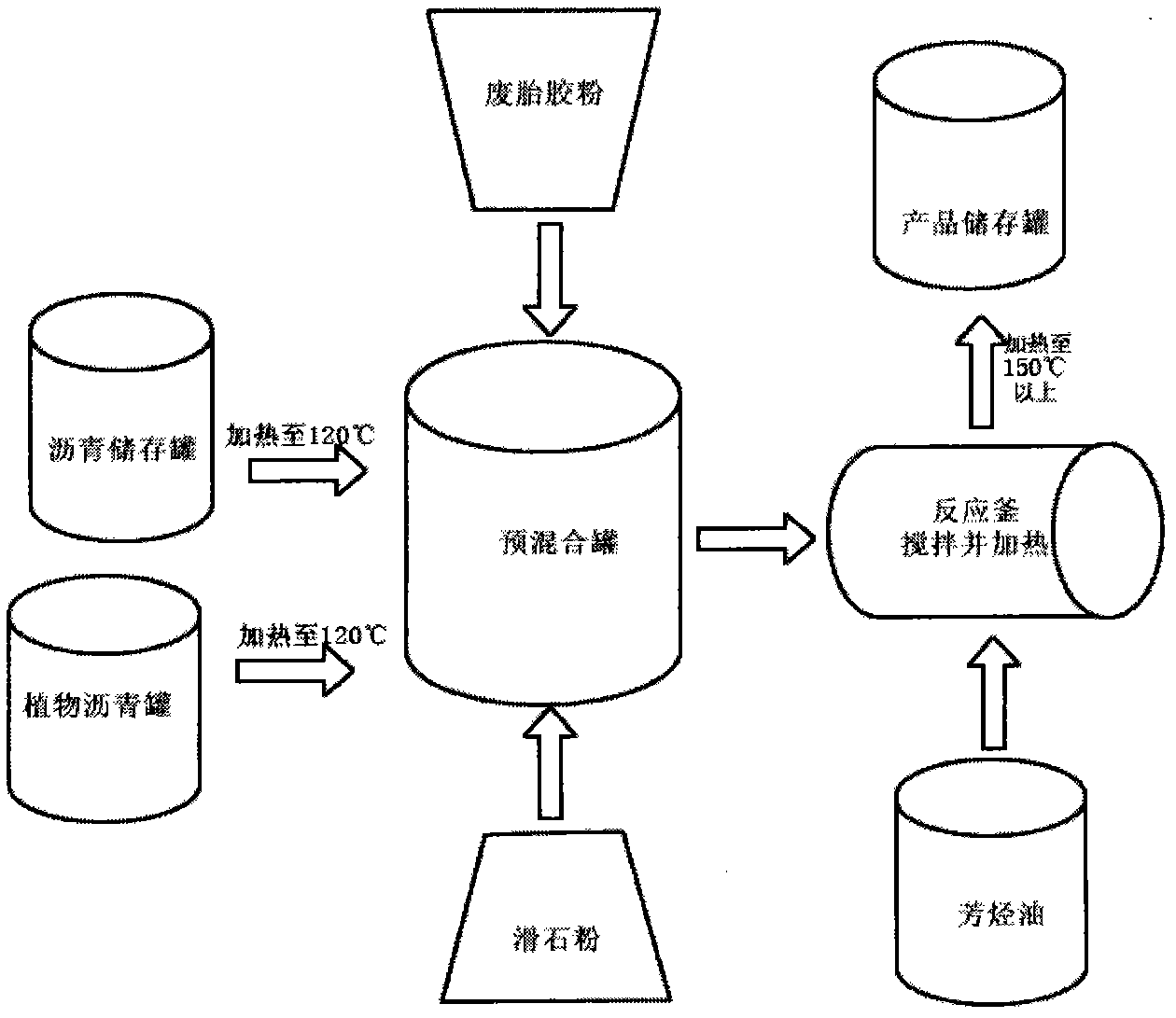

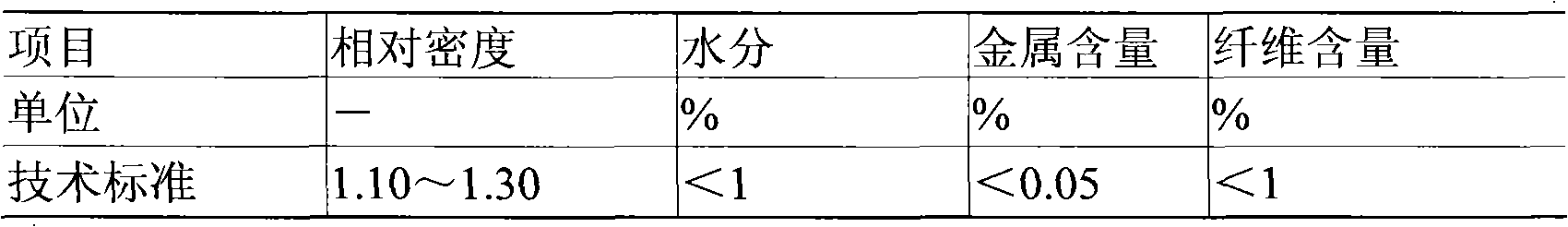

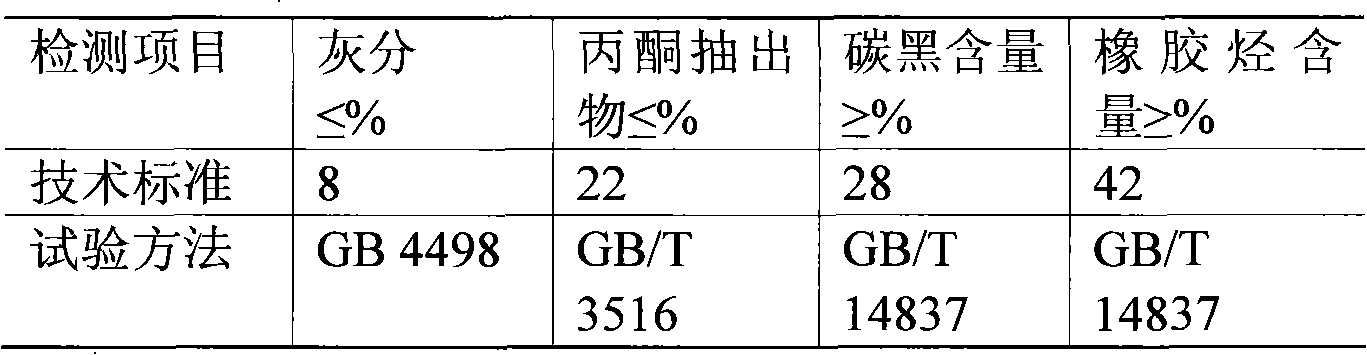

[0024] As shown in the figure, the waste tire rubber powder plant asphalt material and its preparation method first take 50% of petroleum asphalt, 35% of plant asphalt, 25% of waste tire rubber powder, 3% of talcum powder, and 6% of base oil, and then mix the petroleum asphalt After heating with plant asphalt, mix in proportion, add talcum powder and waste tire rubber powder, stir evenly, add aromatic oil, mix evenly under high temperature conditions of 150°C, and react for 120 minutes to prepare asphalt Material.

[0025] After the petroleum asphalt and vegetable asphalt are heated to 120°C, mix and stir evenly, or put the bagged vegetable asphalt directly into the petroleum asphalt heating tank, stir evenly and heat to above 150°C, the mixture of the two kinds of asphalt after heating enters At the same time, waste tire rubber powder and talcum powder also enter the premix tank successively. Several materials are quickly dispersed and mixed under the action of a high-speed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com