Latent heat storage material and preparation method of the latent heat storage material

A technology of latent heat storage and phase change materials, applied in heat exchange materials, chemical instruments and methods, lighting and heating equipment, etc., can solve problems such as impossible storage of solar heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

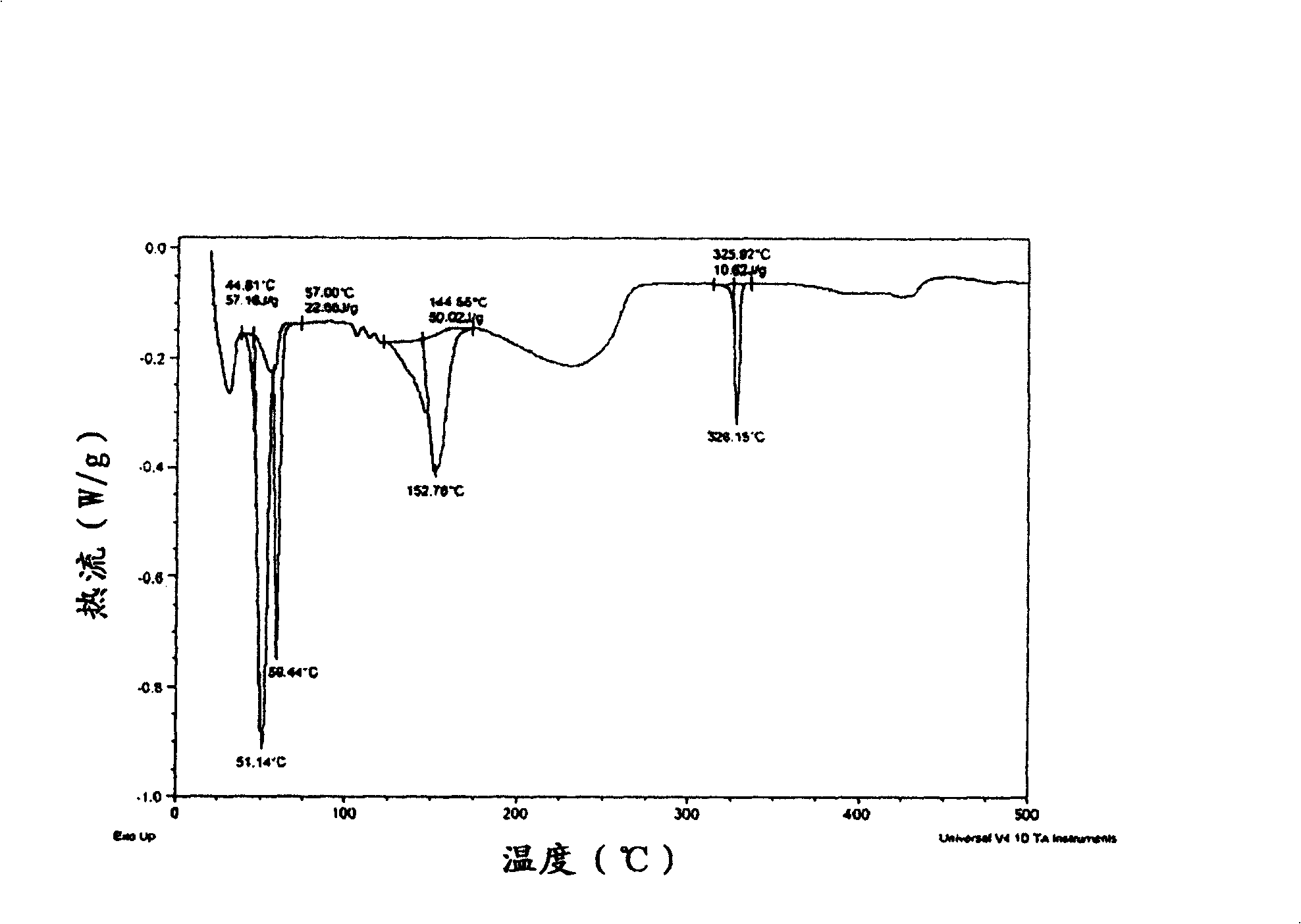

[0033] In one embodiment, sodium acetate trihydrate (melting temperature 58° C.) in powder form is mixed with expanded graphite foil by pulverizing at a mixing ratio of about 85 wt. % to about 15 wt. Graphite powder prepared with 500 micron particles (GFG500). Afterwards, the resulting powder mixture was infiltrated with molten paraffin (RT52) with a melting point of 52° C. supplied by Rubitherm, Hamburg, Germany, and tempered at about 60° C. as image 3 Differential scanning calorimetry (DSC) of the phase change material (PCM) graphite mixture indicated a melting region between the melting point of the paraffin (51.4°C) and that of sodium acetate trihydrate (59.44°C), as shown. The harvested latent heat storage material had a graphite content of about 8.5% by weight.

Embodiment 2

[0034] In another embodiment, the same material as in Example 1 was mixed in a mixing ratio of about 75% by weight to about 25% by weight and impregnated with molten paraffin (RT52). In this embodiment, the harvested latent heat storage material has a graphite content of about 7.7% by weight. Figure 4 Results are shown for two separate melting steps over several heating / cooling cycles.

Embodiment 3

[0035] For comparison with the previously described examples, in this embodiment a mixture of expanded graphite (20% by weight) and two miscible salts, potassium nitrate (KNO 3 ) (43% by weight) and sodium nitrate (NaNO 3 ) (37% by weight) mixture to produce latent heat storage composites. KNO 3 has a melting point of 337°C and NaNO 3 The melting point is 307°C. In a laboratory mixer, mix the expanded graphite with solid NaNO 3 powder. In expanded graphite and NaNO 3 The powder mixture was cast on molten KNO at a temperature of about 345 °C 3 . The salt-graphite mixture was cooled to room temperature and the melting temperature of the resulting composite was determined by DSC. This latent heat storage composite has a unique melting point of 220°C rather than phase transitioning over a temperature range as demonstrated in Example 1 using a phase change material that is immiscible.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com