Method for drawing dual cones on preformed rod

A technology for preforms and optical fiber preforms, which is applied to manufacturing tools, glass manufacturing equipment, etc., can solve the problems of fiber preform taper loss, operation difficulty, material waste, etc. that are not fundamentally solved, and save raw materials and simplify processes , the effect of uniform cone shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for drawing an optical fiber preform bicone, comprising the following steps:

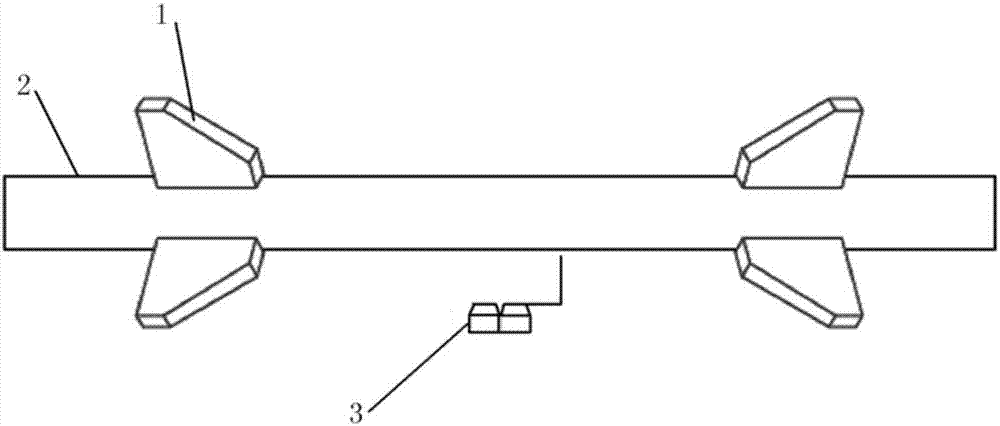

[0038] 1) Preheating process, such as figure 1 Shown: Fix the preform on the two fixtures on the operating platform to ensure that the preform is in a horizontal position; turn on the blowtorch and aim at the tapered part for pre-burning until the surface glass is in a molten state;

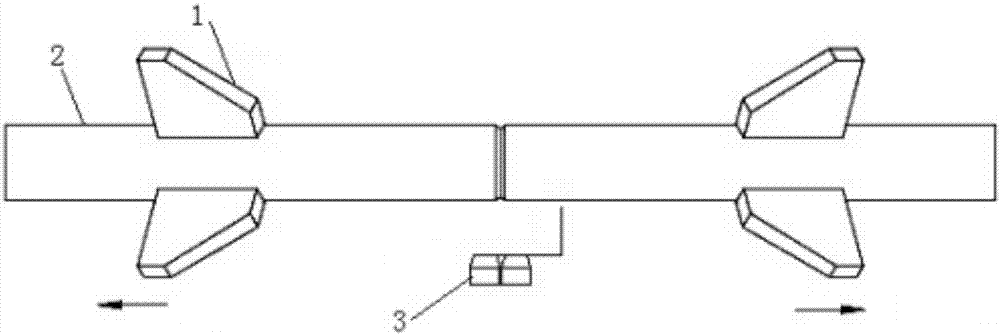

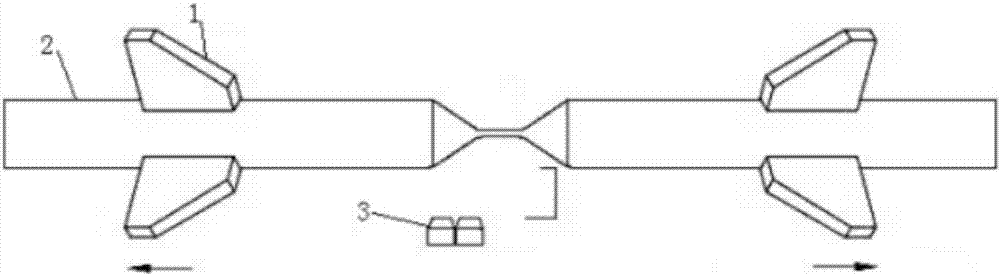

[0039] 2) Tapering process, such as figure 1 As shown: the process is divided into N stages of stretching: when the surface glass of the preform rod is in a molten state, move the fixture slowly so that the distance between the left and right fixtures increases to the set distance, stop the movement of the fixture, this is the first stage of stretching Stretch; point the blowtorch at the part of the preform with the largest diameter change and continue heating, move the clamp, and repeat the operation of the first stage, which is the second stage of stretching; repeat until the Nth stage of stretching ...

Embodiment 2

[0053] A method for drawing an optical fiber preform bicone, comprising the following steps:

[0054] Such as figure 1 As shown, the preheating process: First, clamp the preform rod on the claws at both ends, confirm the level of the preform rod, align the lamp head with the position where the taper needs to be drawn, and preheat the preform rod by burning propane and oxygen. The best distance between the preform rods is 50mm. When preheating, first use one lamp head to pre-burn. After 8-10 minutes, turn on the second lamp head and continue to increase the temperature of the preform rods so that the temperature can gradually penetrate. After 25-30 minutes, After confirming that the surface glass of the preform is in a molten state, taper drawing is started.

[0055] Such as figure 2 As shown, the tapering process: fix the left claw, move the right claw, lock the claw after moving 18-20mm, continue to heat the lamp head to the position where the diameter of the preform is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com