Production process of fiber preform rod

A technology for optical fiber preforms and production methods, which is applied in the direction of glass fiber products, manufacturing tools, glass manufacturing equipment, etc., can solve problems such as difficulties, changes in the refractive index of the critical surface of the core and cladding, and affect the optical performance of optical fibers, etc., to achieve improved Optical fiber quality, improved manufacturing process, good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

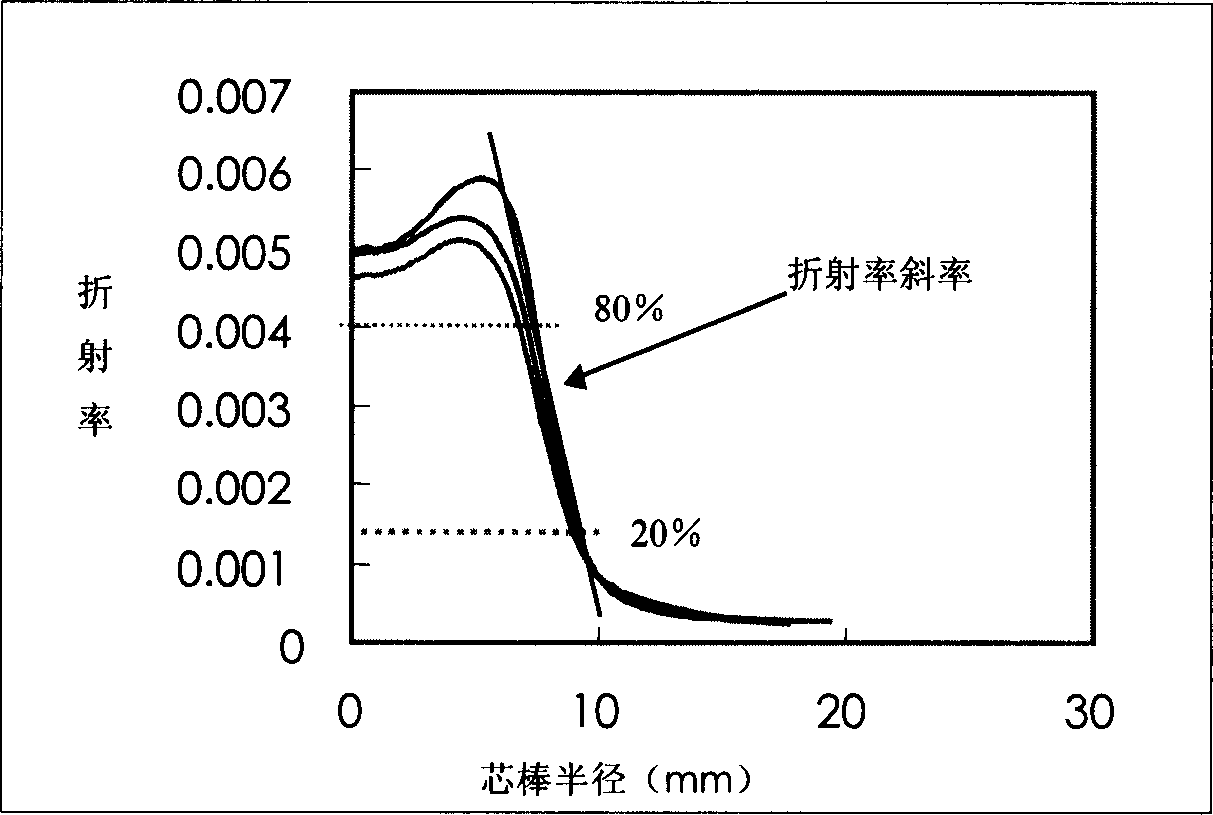

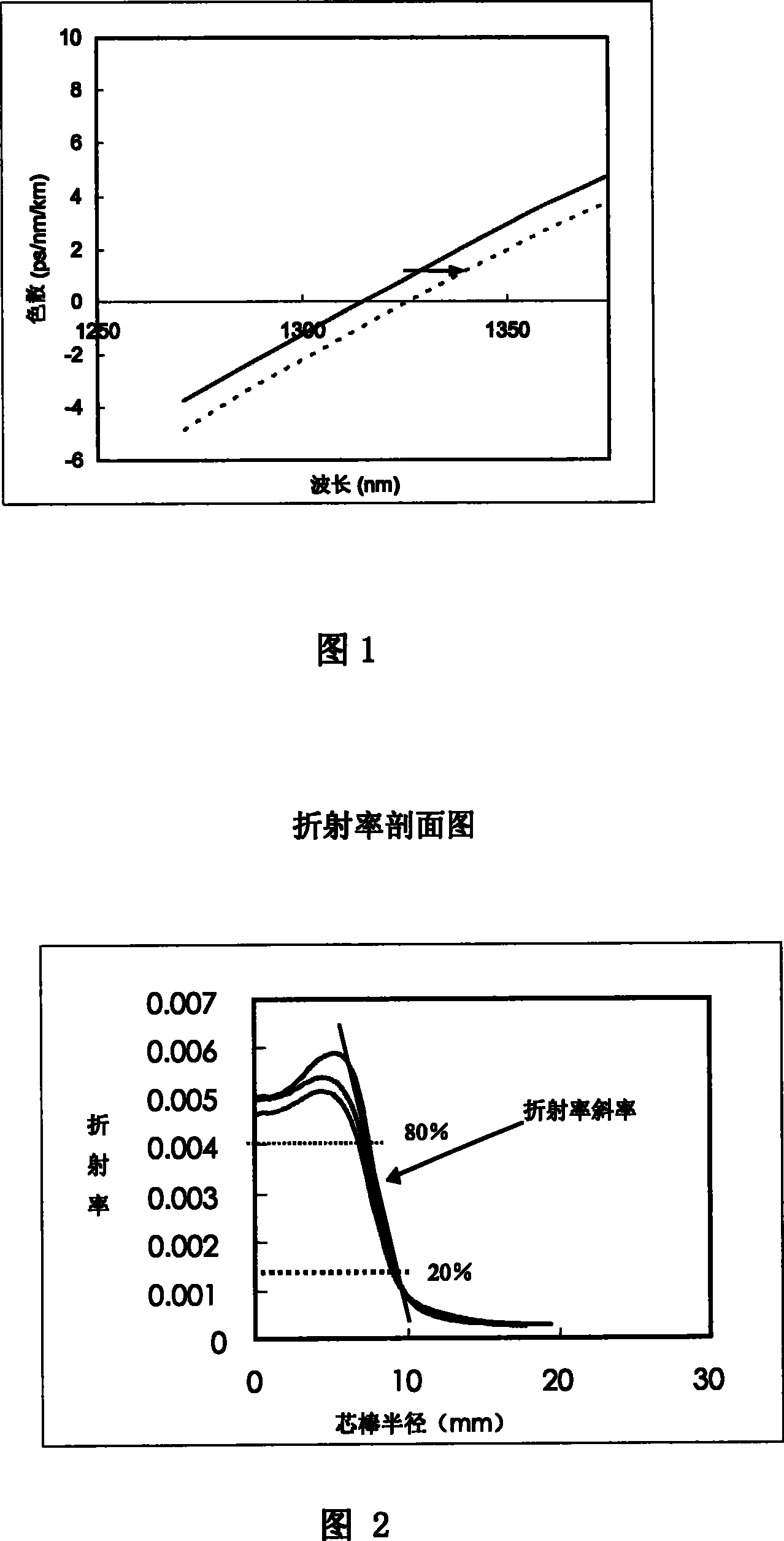

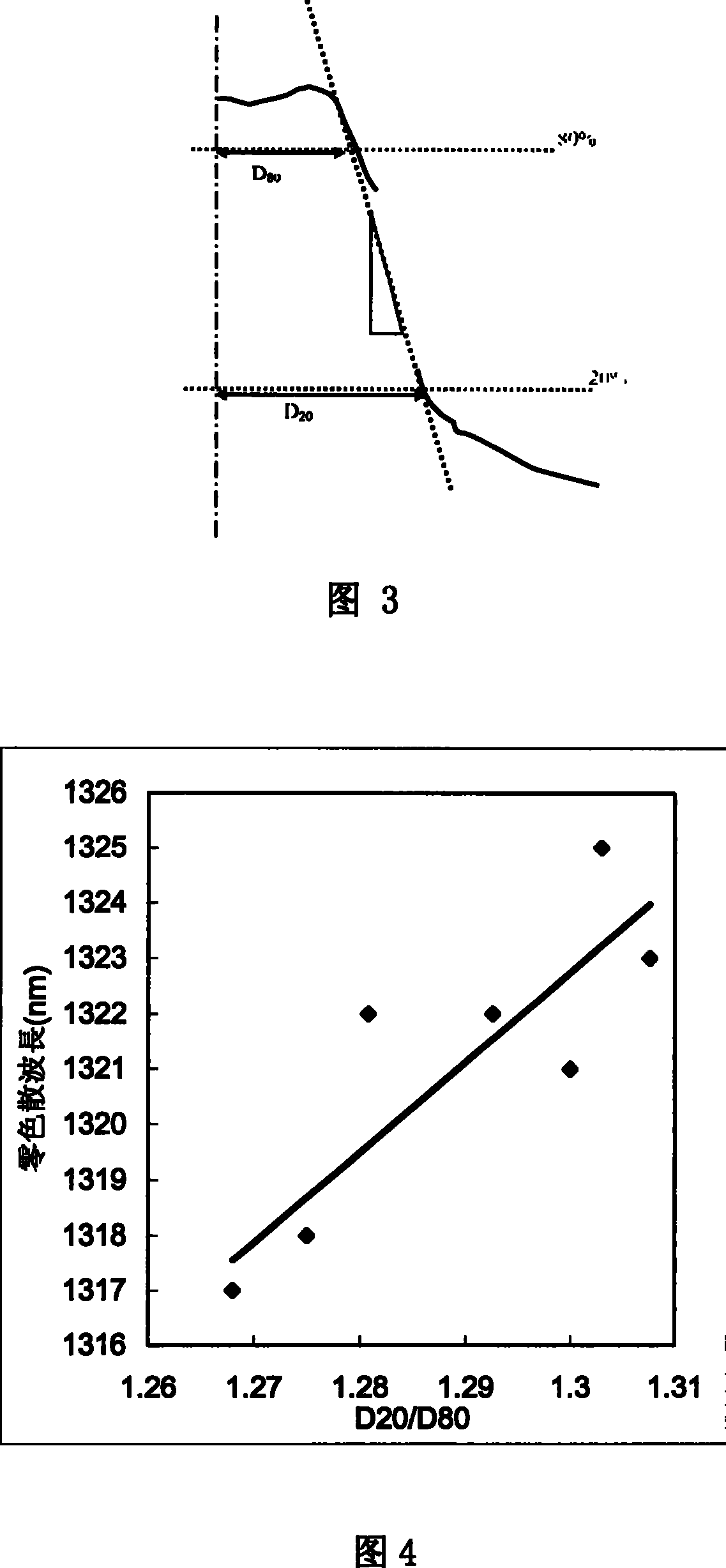

[0016] A method for producing an optical fiber preform, comprising the steps of conventionally producing a core rod and making a cladding, controlling the refractive index distribution of the preform during the synthesis of the loose body to dehydration and vitrification, and the diameter of the preform is D 20 with D 80 The ratio of ≤1.3, where D 20 with D 80 Respectively represent the diameters of the two places when the refractive index of the section of the preform is 20% and 80% relative to the maximum refractive index of the center. Among them, three different methods are used to change the shape of the refractive index profile of the preform rod section.

[0017] Method 1: During the dehydration of the loose body in the preform production process, the mixture of inert gas (such as helium, the supply rate is 20-50L / min) and dehydration gas (such as chlorine gas, the supply rate is 150-300cc / min) Oxygen is added to the environment, and the oxygen flow rate is 0.1-10L / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com