Glass knife disc and preparing method thereof

A manufacturing method and glass scribing technology, applied in glass manufacturing equipment, manufacturing tools, glass cutting devices, etc., can solve the problems of low hardness of cemented carbide, low scoring performance and high manufacturing cost, achieve strong welding strength, reduce Production cost, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

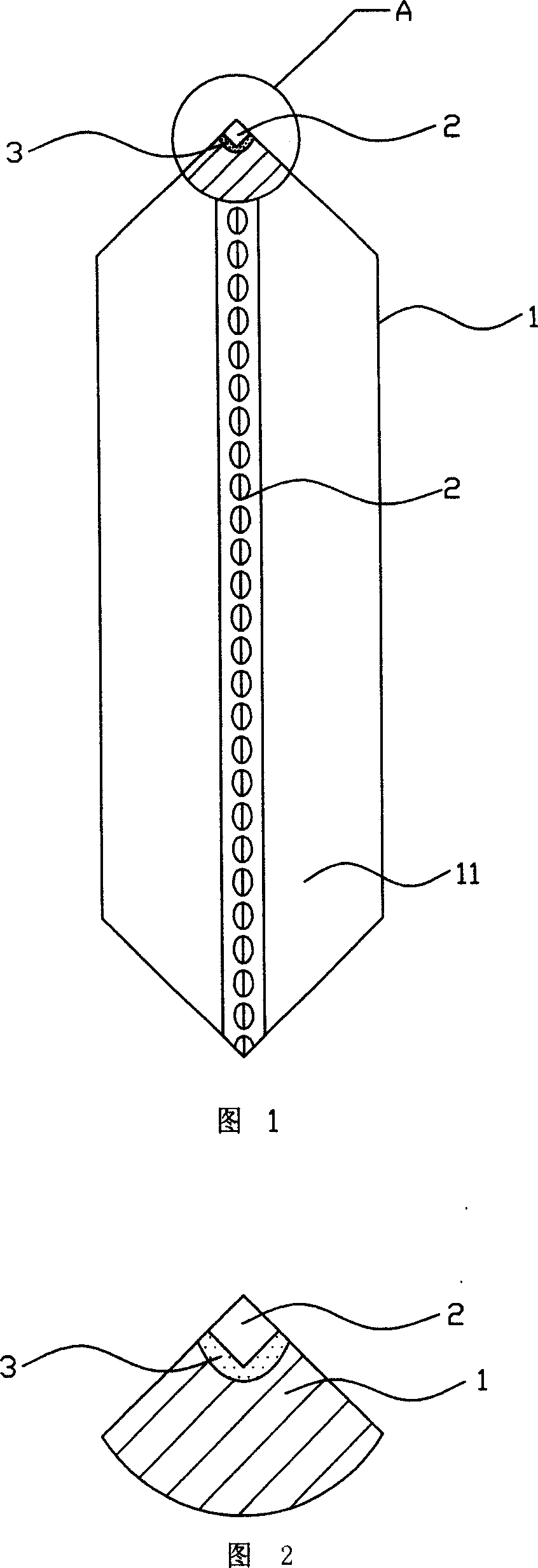

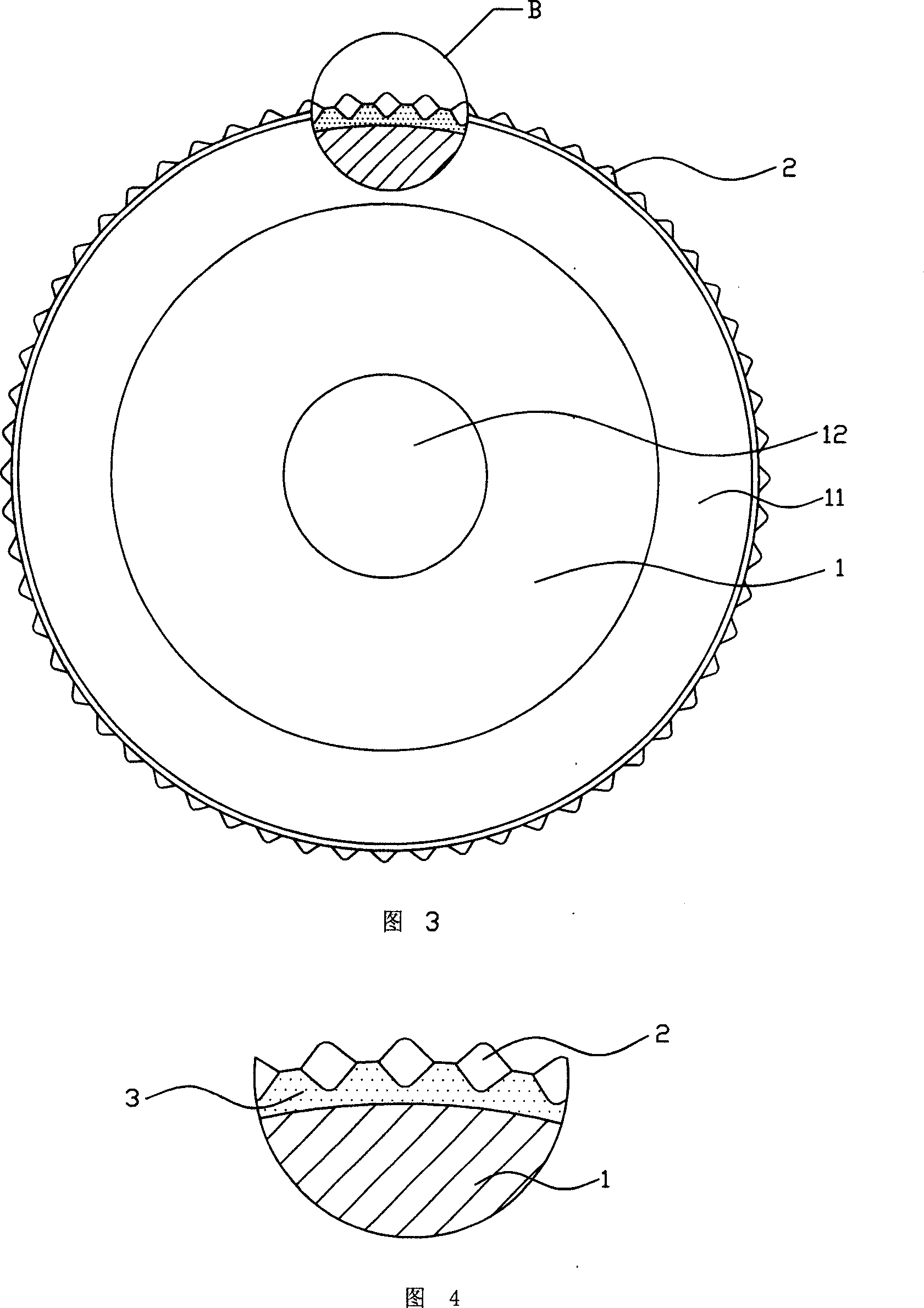

[0024] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0025] As shown in Figures 1 and 3 of the glass scribing disc of the present invention, the disc 1 is disc-shaped and made of steel. A central hole 12 is provided at the center, and a row of diamond particles 2 are brazed to the tip of the blade portion 11, and the particle size of the diamond particles 2 is #300. The brazing layer 3 is a copper-silver alloy containing at least 3% by weight of titanium.

[0026] The manufacturing method of the aforementioned glass scribing disc is as follows:

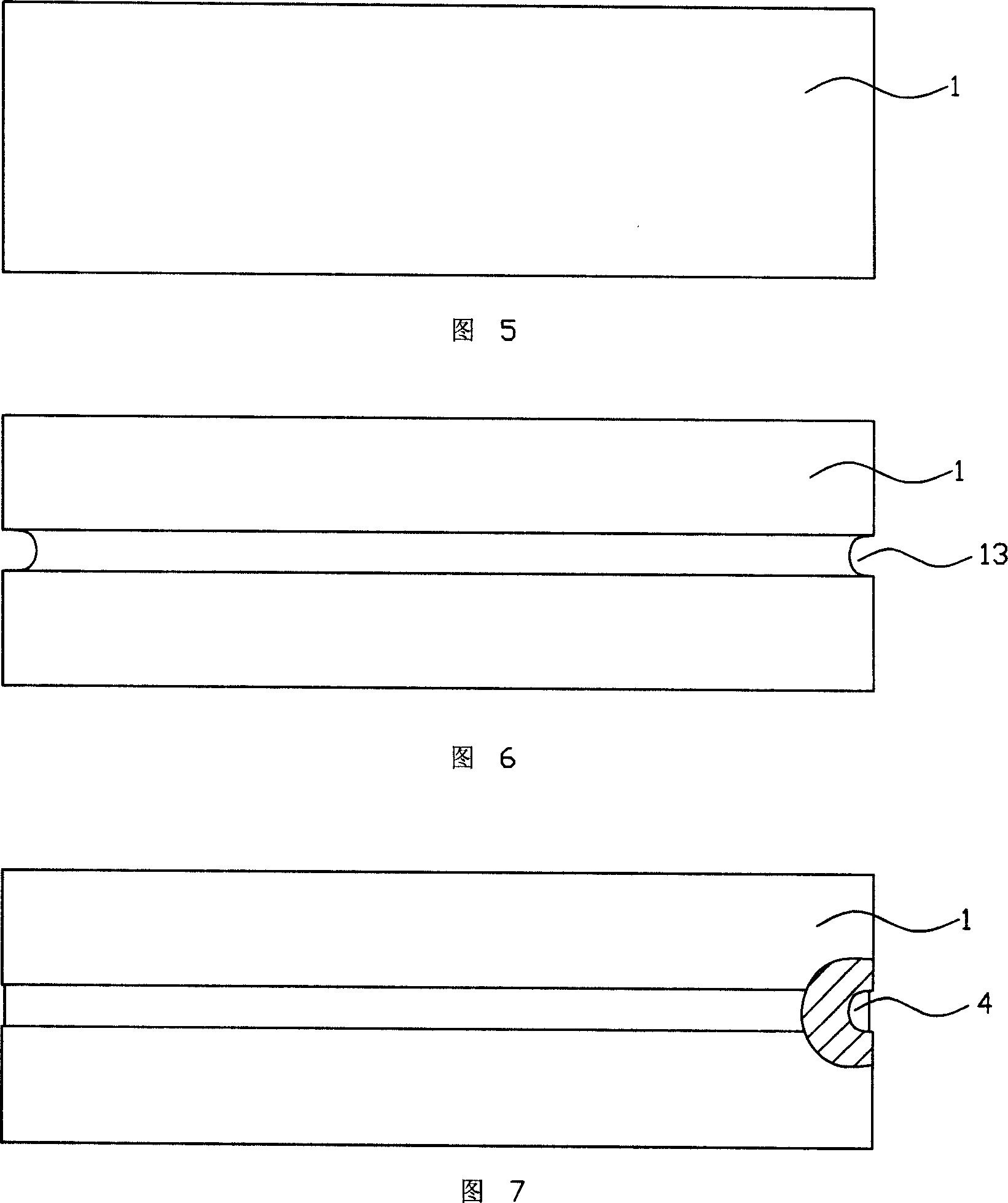

[0027] Grind out a "U" shaped groove 13 (as shown in Figure 6) with a diamond grinding wheel on the circular disk 1 (as shown in Figure 5); Fig. 7), the diamond particles 2 are stuck on the viscose 4, and the copper-silver alloy brazing material powder containing at least 3% by weight of titanium is spread in the groove, placed in a vacuum brazing furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com