Glass micro-etching cutting device

A cutting device and glass micro technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high labor intensity and low cutting efficiency, and achieve the effect of reducing labor intensity and improving glass cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

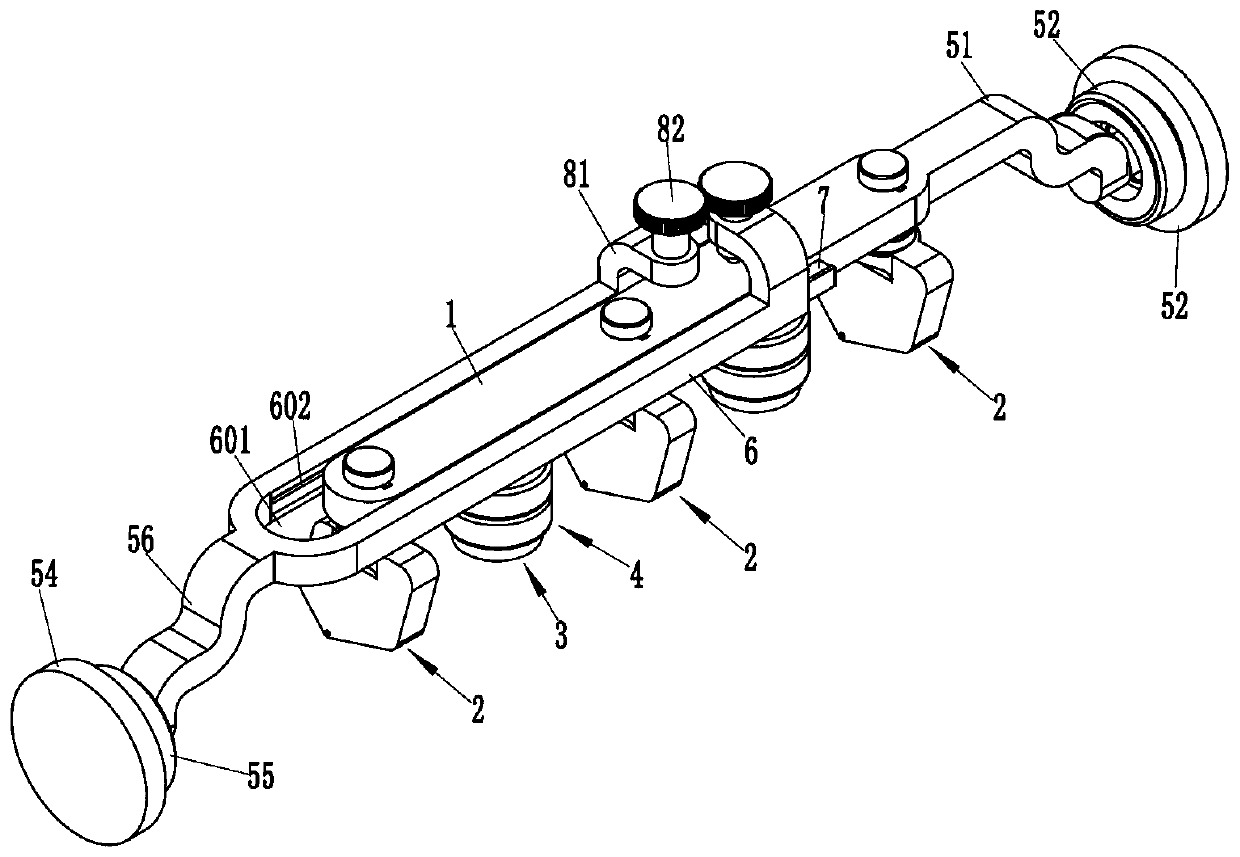

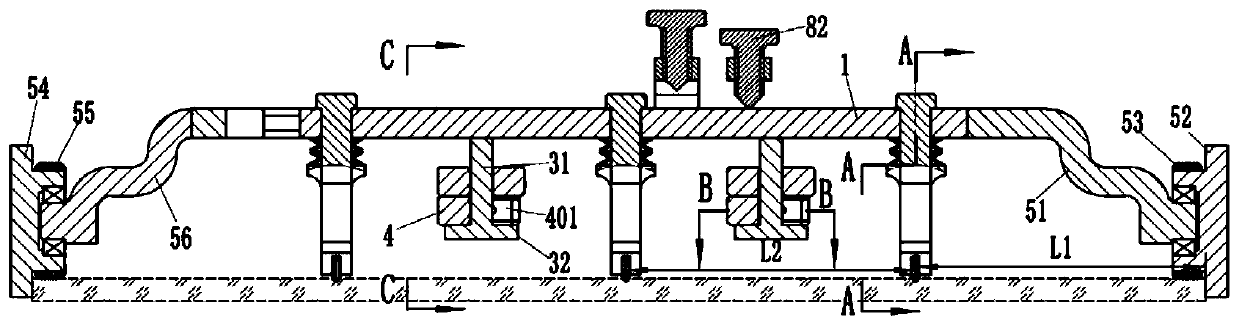

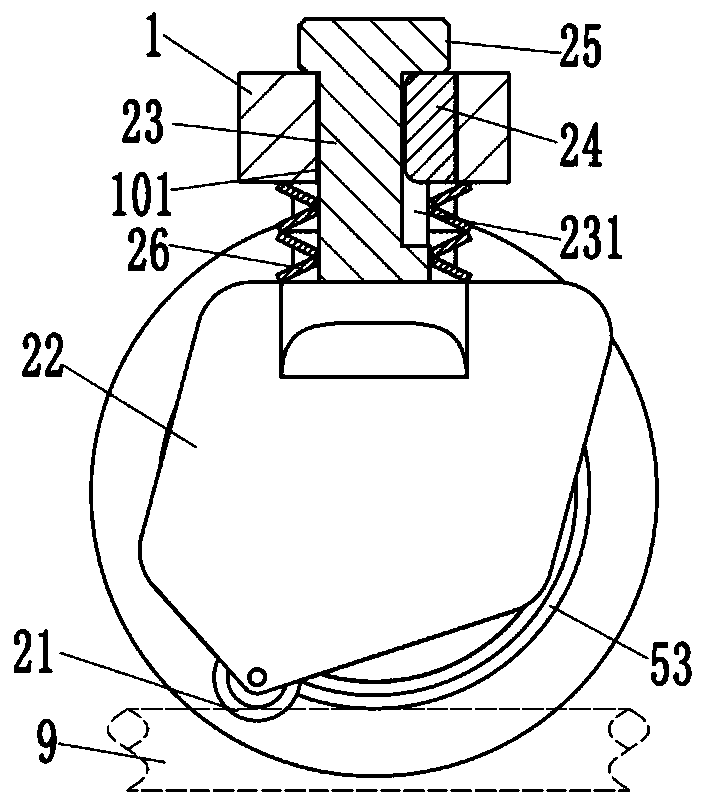

[0026] Examples, see e.g. Figure 1 to Figure 5 As shown, a glass micro-scoring and cutting device includes a walking beam 1, a plurality of linear and uniform glass knives 2 are connected to the walking beam 1, and a plurality of load-bearing block placement frames are fixed on the lower bottom surface of the walking beam 1 3. A number of load-bearing blocks 4 are arranged on the load-bearing block placement frame 3, and a first connecting arm 51 is fixed on the right side wall of the walking beam 1, and the outer end of the first connecting arm 51 is hinged with a step cylinder-shaped positioning Wheel 52, the outer wall of the inner side small end of positioning wheel 52 is inserted and sleeved on the first rubber sleeve 53, and the right side of described walking beam 1 is provided with the auxiliary wheel 54 that is symmetrical with positioning wheel 52, and described positioning wheel 52 and auxiliary The wheel 54 is arranged on the same axis, and the outer wall of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com