Multifunctional glass cutting apparatus

A glass cutting and multi-functional technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve problems such as low efficiency, inability to complete complex shapes, and inaccurate cutting of cutting equipment, so as to achieve low investment cost and cutting The effect of high efficiency and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

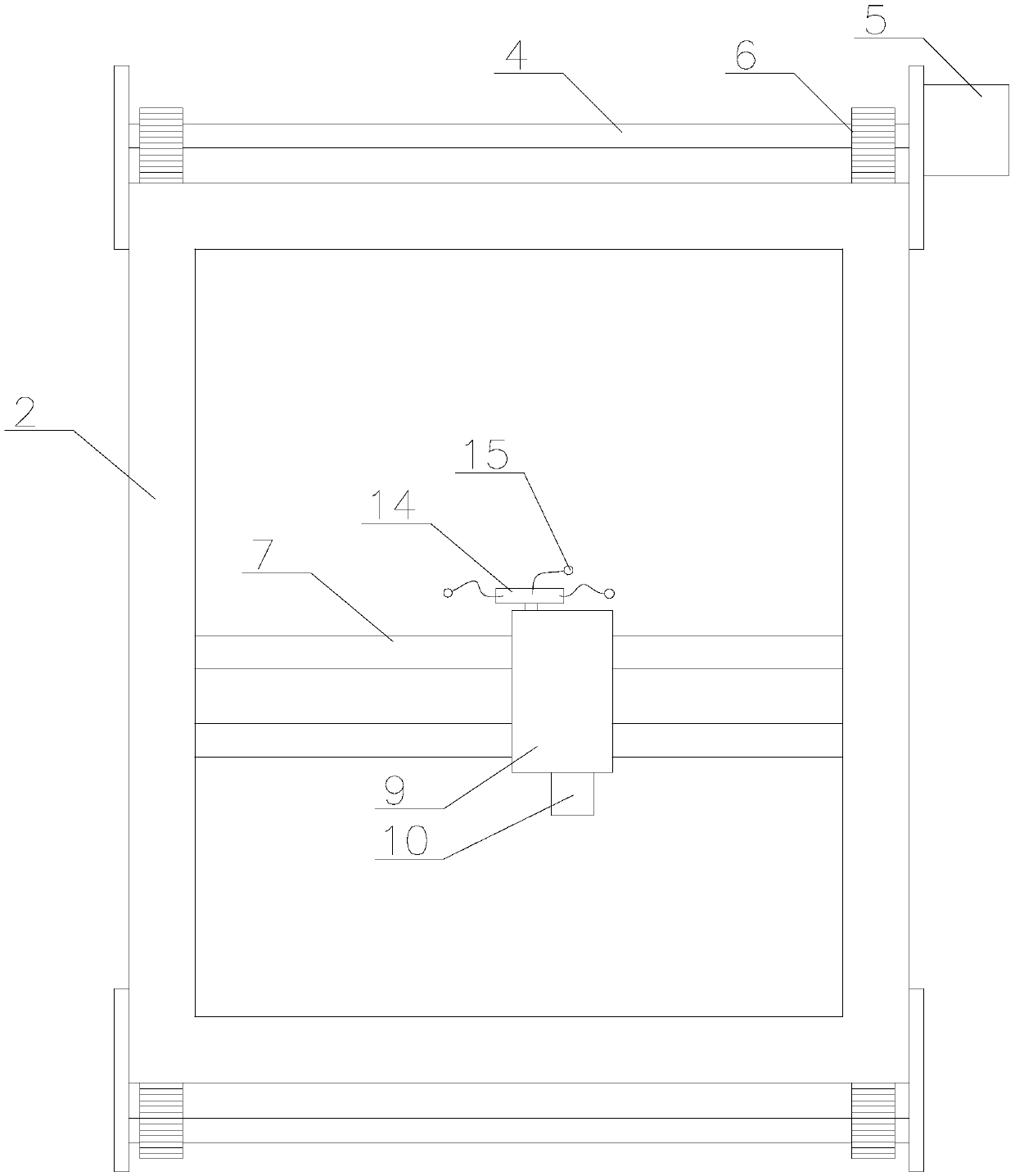

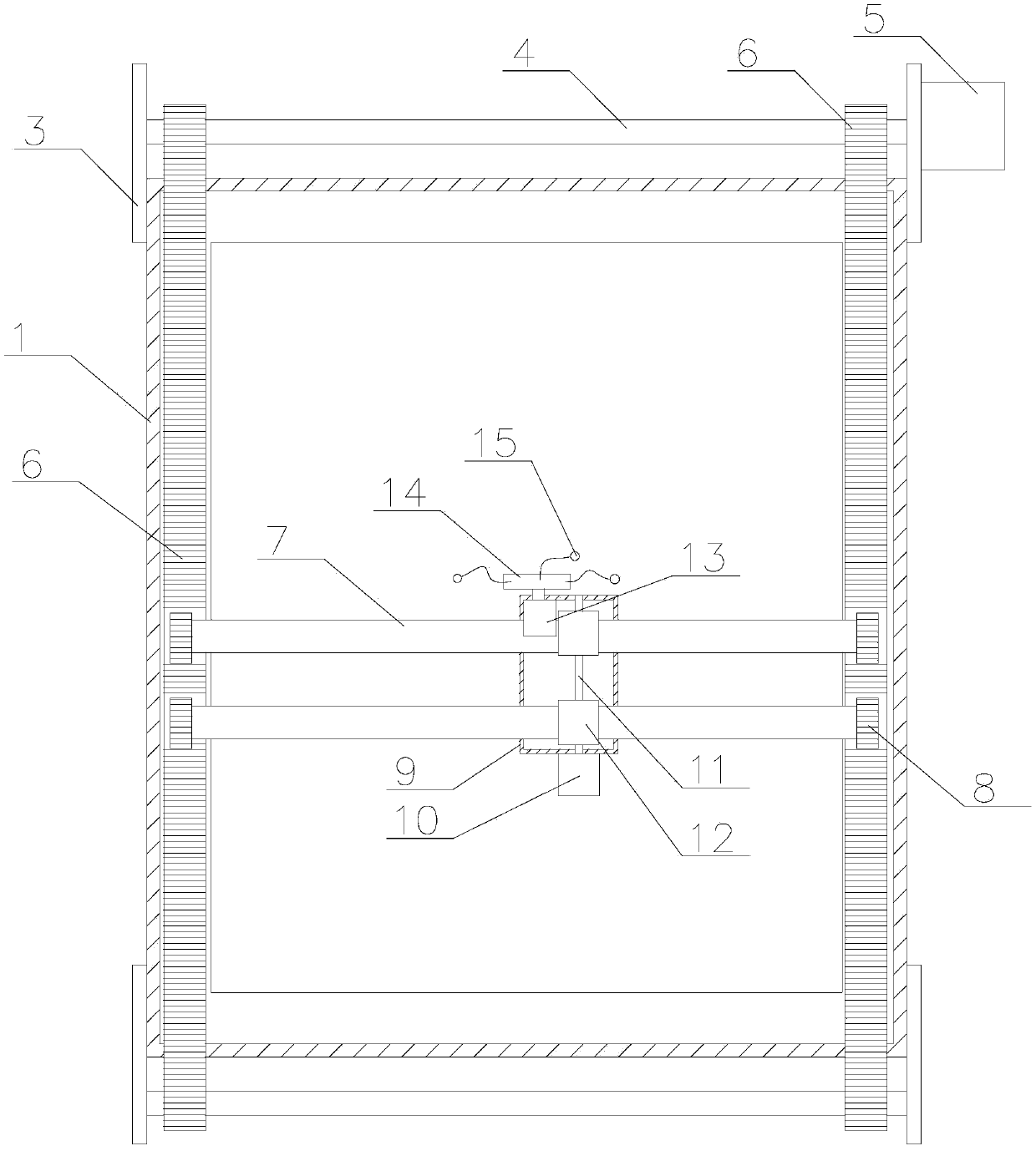

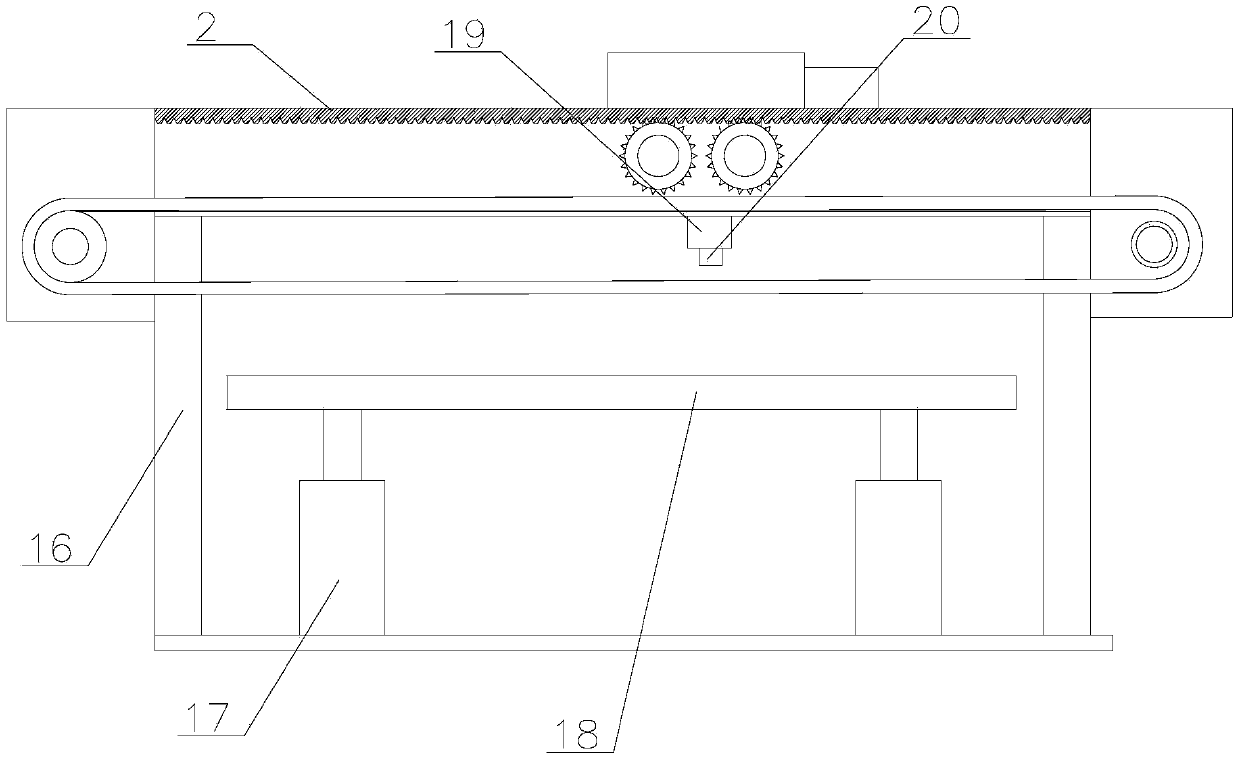

[0016] refer to figure 1 , figure 2 and image 3 , a multifunctional glass cutting device of the present invention, comprising a bracket 1, a cover plate 2, a guard plate 3, a belt drive shaft 4, a longitudinal movement motor 5, a transmission belt 6, a transverse guide rail 7, a driven gear 8, a transverse movement seat 9, Lateral motion motor 10, lateral motion transmission shaft 11, pressure roller 12, knock motor 13, supporting leg 16, hydraulic cylinder 17, glass pallet 18, glass knife holder 19 and glass knife 20, described support 1 bottom is provided with Outriggers 16, 2-4 hydraulic cylinders 17 are arranged between the said outriggers 16, glass pallets 18 are arranged on said hydraulic cylinders 17, and measuring guard boards 3 and belt transmission are respectively arranged on both sides of said support 1 Shaft 4, a longitudinal motion motor 5 is installed on the guard plate 3, the longitudinal motion motor 5 is connected to the belt drive shaft 4, a pulley is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com