Glass-metal composite plate as well as manufacturing method and application thereof

A technology of metal compounding and manufacturing methods, applied in the direction of metal layered products, chemical instruments and methods, glass/slag layered products, etc., to achieve the effect of improving the flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

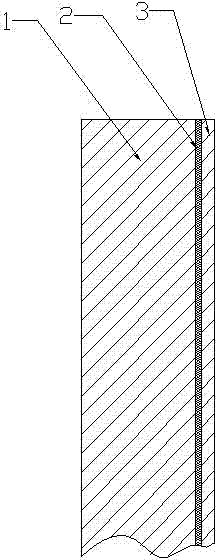

[0023] figure 1 In the method, the glass plate (1) and the thin metal sheet (3) are combined with an adhesive (2) to form a glass-metal composite plate.

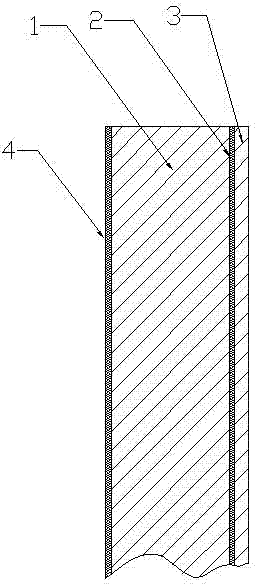

[0024] figure 2 In the process, a layer of anti-ultraviolet paint (4) is coated on the non-adhesive side of the glass plate (1) to increase the service life of the adhesive (2).

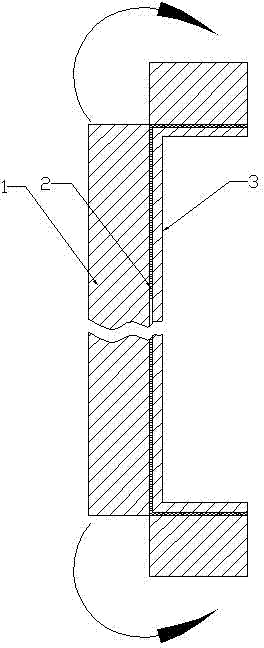

[0025] image 3 In the process, the glass plate (1) in the glass-metal composite plate is cut and bent at the desired place, so that various profiles and products (such as furniture, lamps, partitions, etc.) can be made.

[0026] Figure 4 and Figure 5 In this method, a glass-metal composite sheet is bent into a box shape and used as the bottom of the box (A), and another glass-metal composite sheet is used as the box cover (B), and the outer dimensions of the box cover (B) are the same as The inside of the upper opening of the box bottom (A) matches the size of the periphery, and welds and seals it with solder (5) along the coincident perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com