Glass cutter capable of cutting arcs on side face and right angle

A glass knife and arc technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of inconvenient operation, not easy to fix, and can only cut straight lines, etc., to achieve space saving, convenient operation, The effect of reducing the number of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific implementation method the present invention is further described:

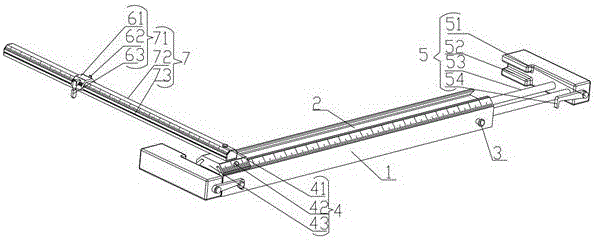

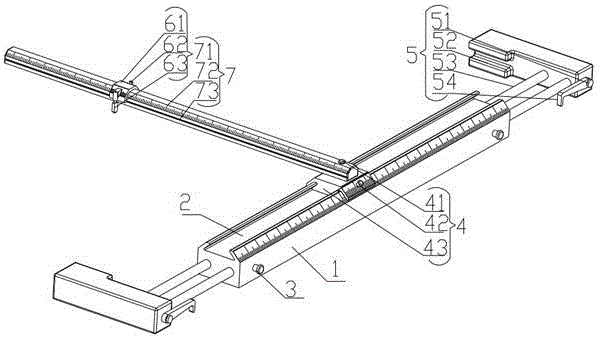

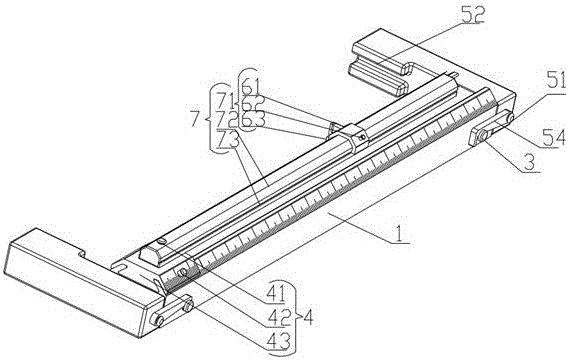

[0016] to combine figure 1 , 2 , 3, 4, it can be seen that: a glass knife that can cut circular arcs on the side and corners, including a base 1, a dovetail slideway 2, a fixed table 3, a main sliding conductor 4, a clamping arm 5 and a cutting device 7, its It is characterized in that: the main sliding conductor 4 includes a main rotating shaft 41, a main fixing screw 42 and a dovetail stand 43, the main sliding conductor 4 slides on the dovetail groove slideway 2 through the dovetail stand 43, and moves to the desired cutting position , and then the main sliding conductor 4 is fixed on the base 1 by the main fixing screw 42 . The clamping arm 5 includes an auxiliary rotating shaft 51, a U-shaped anti-slip pad 52, a tension rod 53 and a fixed hook 54. The U-shaped anti-slip pad 52 can embed glass or tiles without slipping, and then through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com