Battery piece PECVD post-plating film reworking piece processing method

A processing method and cell technology, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of increasing the fragmentation rate of silicon wafers, increasing production costs, wasting acid materials, etc., and reducing the fragmentation rate of cell chips. , the effect of reducing the amount of use and reducing the concentration of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

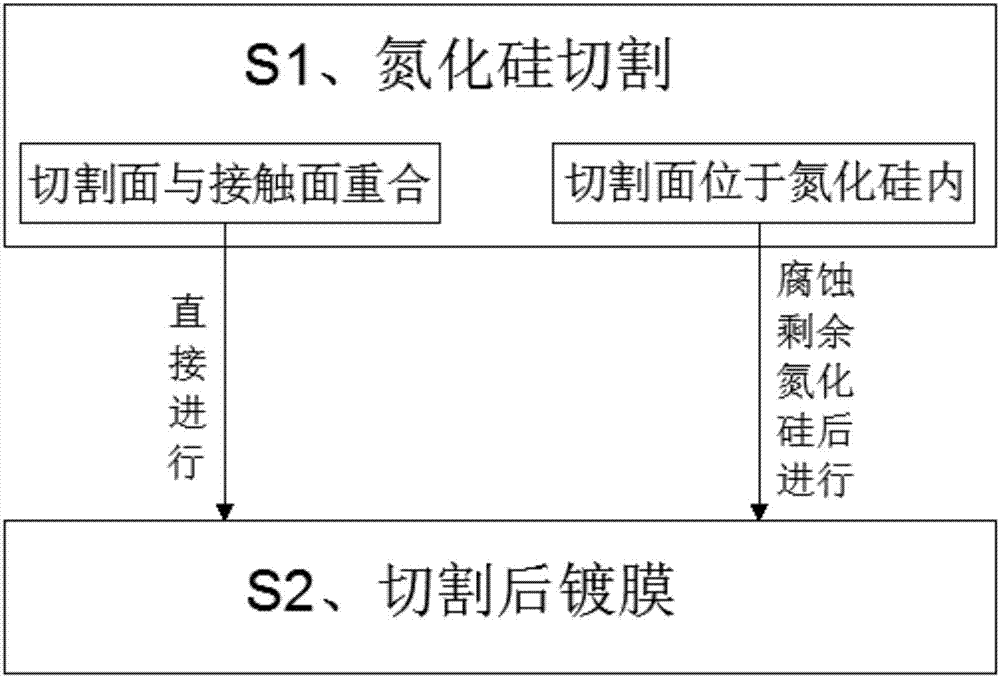

[0026] A method for processing a reworked battery sheet after PECVD coating, comprising the following steps:

[0027] S1. Silicon nitride cutting: use a glass knife to cut and remove the silicon nitride on the surface of the cell;

[0028] First of all, place the color difference rework sheet in a clean environment to avoid pollution to the cell. Since the thickness of the cell is in microns, it is difficult to distinguish with the naked eye, so the silicon wafer can be operated under a microscope.

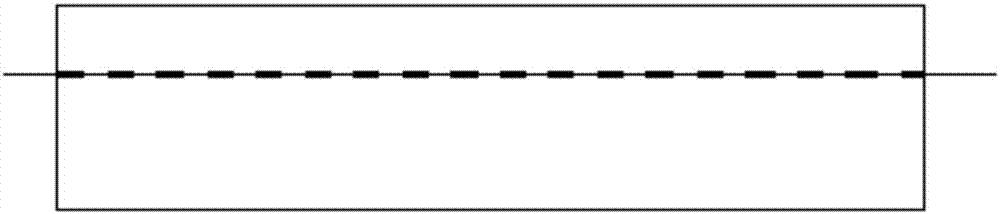

[0029] As attached to the manual figure 2 As shown, the thick dotted line in the figure is the contact surface between the cell and the deposited silicon nitride, and then the glass knife is controlled to align the contact surface. The cutting surface of the glass knife should always be kept parallel to the contact surface. In this embodiment, the cutting surface and the contact surface Overlapping, the thin solid line in the figure is the cutting surface line. After overlapping...

Embodiment 2

[0034] A method for processing a reworked battery sheet after PECVD coating, comprising the following steps:

[0035] S1. Silicon nitride cutting: use a glass knife to cut and remove the silicon nitride on the surface of the cell;

[0036] First of all, place the color difference rework sheet in a clean environment to avoid pollution to the cell. Since the thickness of the cell is in microns, it is difficult to distinguish with the naked eye, so the silicon wafer can be operated under a microscope.

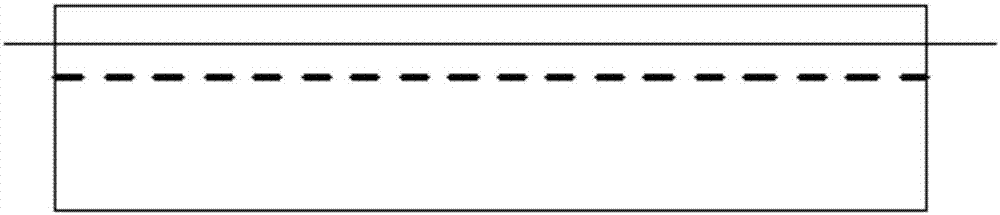

[0037] As attached to the manual image 3 As shown, the thick dotted line in the figure is still the contact surface between the cell and the deposited silicon nitride, and then the glass knife is controlled to align the silicon nitride. The cutting surface of the glass knife should always be kept parallel to the contact surface. In this embodiment, the cutting surface is located In the silicon nitride, the thin solid line in the figure is the cutting surface line, the glass knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com