Filter screen mounting structure, fan assembly and range hood

An installation structure and filter screen technology, which is applied in the fields of filter screen installation structure, fan components, range hood, etc., can solve the problems of inconvenient filter screen disassembly and assembly, and achieve the effects of reducing the difficulty of alignment, convenient installation, and convenient custom processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

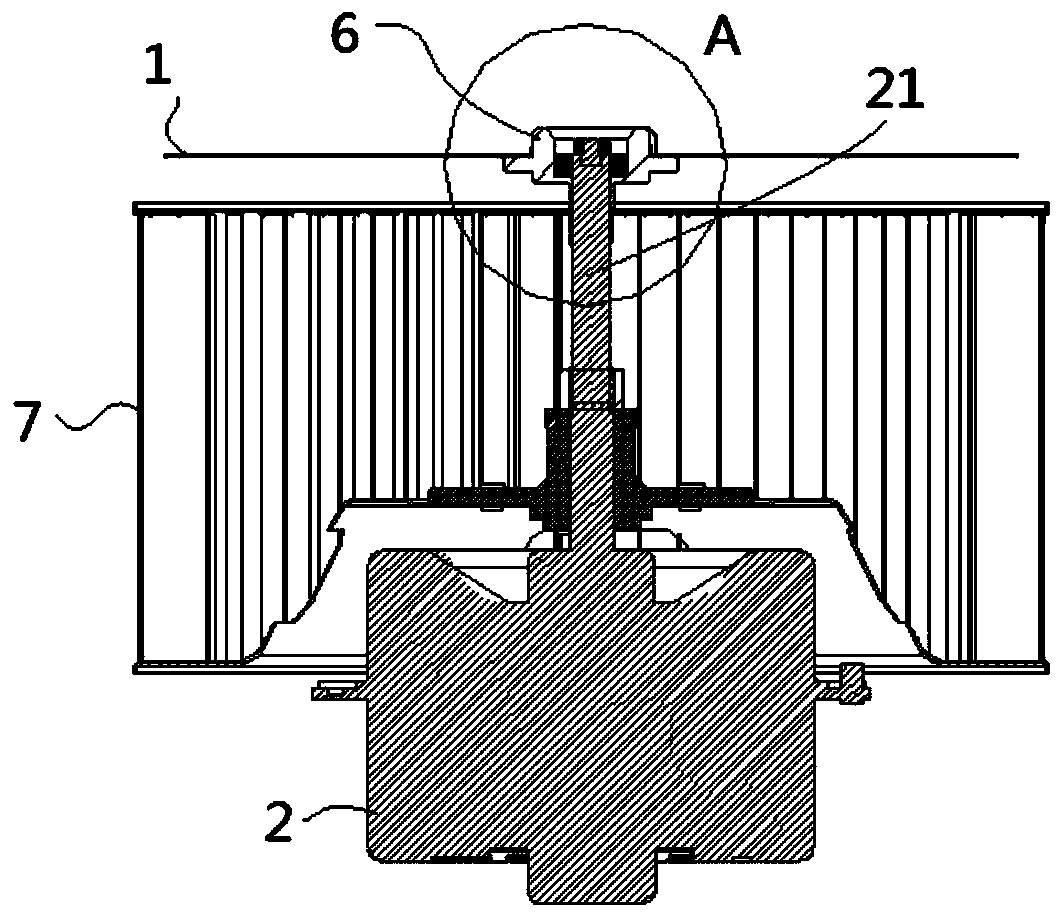

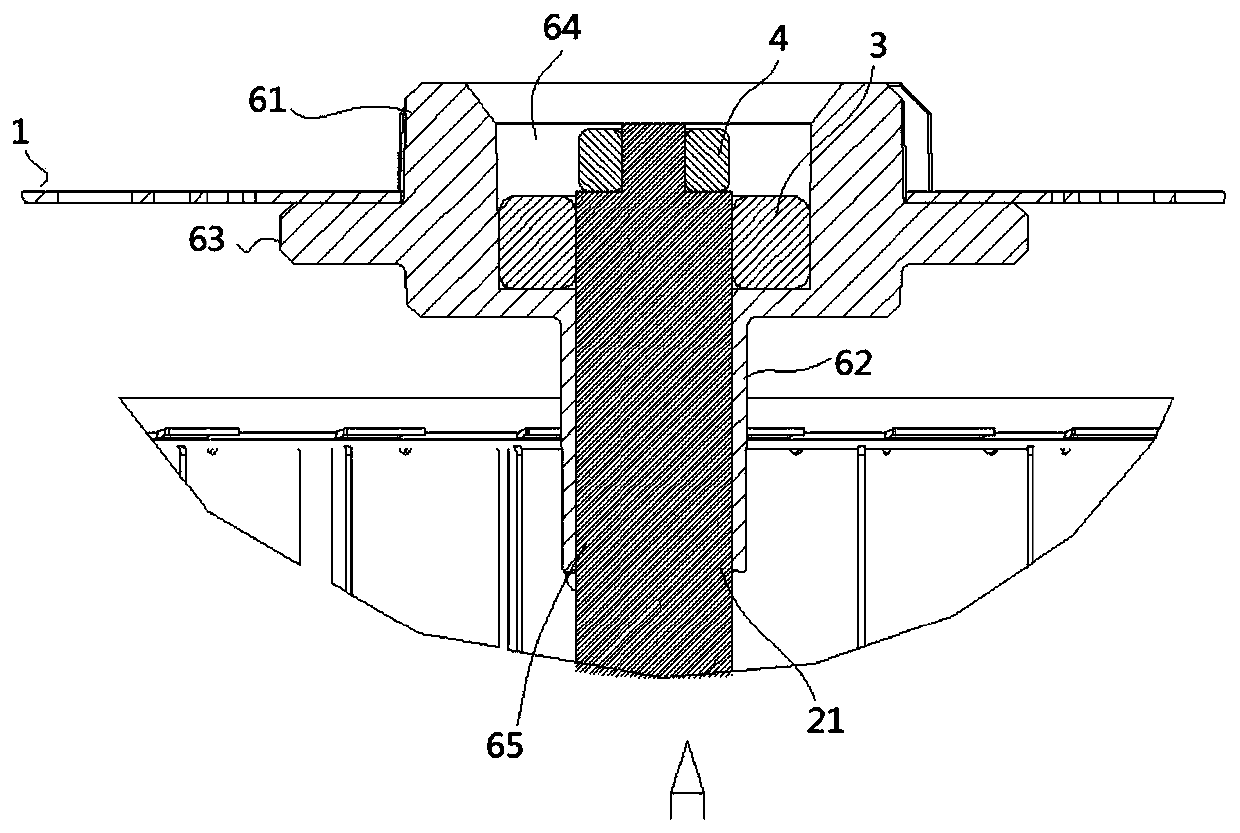

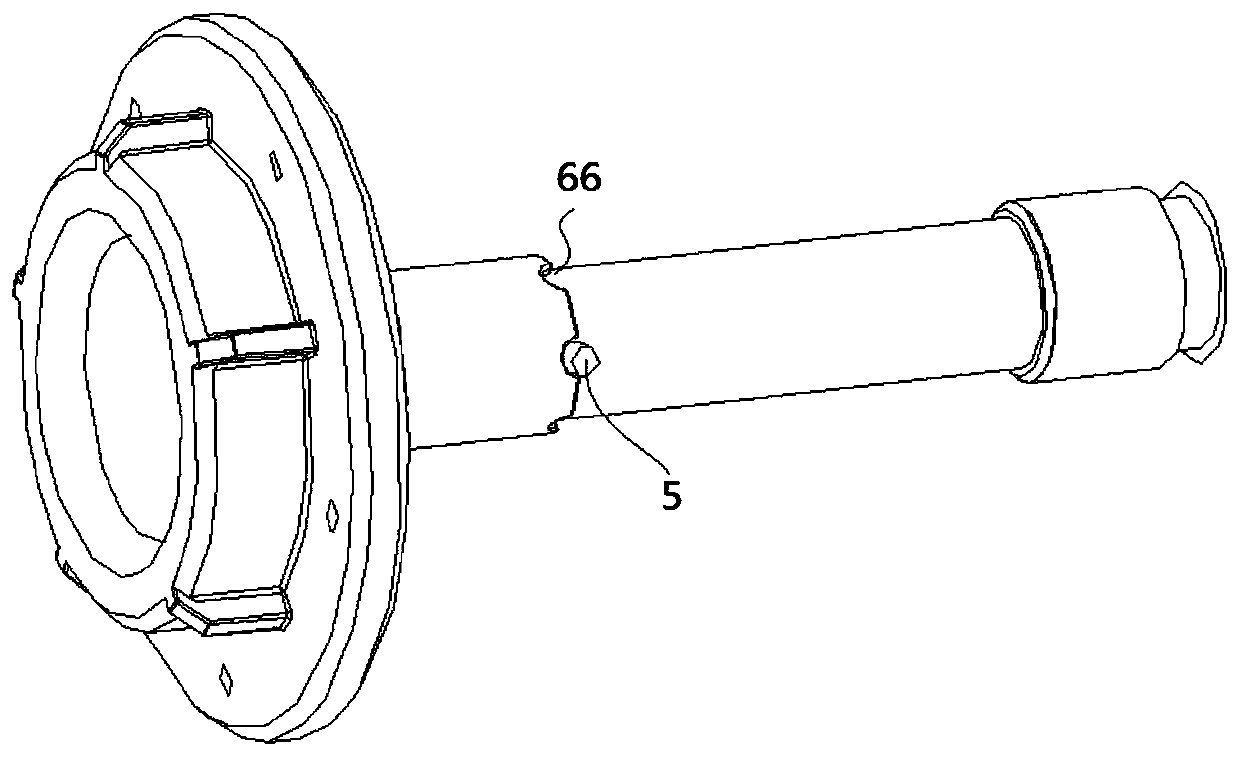

[0048] Figure 1 to Figure 5 As shown, a filter screen installation structure provided in this embodiment includes a motor 2 and a filter screen assembly detachably mounted on the motor shaft 21 of the motor 2, and also includes: a first magnetic member 3 arranged on the filter screen assembly; and the second magnetic part 4 arranged on the motor shaft 21, the first magnetic part 3 and the second magnetic part 4 are arranged oppositely, and after the filter screen assembly reaches the preset installation position, the first magnetic part 3 is located at the first The two magnetic parts 4 are under the same polarity and mutually repulsive; the limiting part 5 is arranged on the motor shaft 21, and the filter screen assembly abuts against the limiting part 5 under the action of mutual repulsion. The filter screen assembly in this embodiment has the function of separating oil and dirt, and the first magnetic part 3 is arranged on it. When the user installs it, the first magnetic ...

Embodiment 2

[0066] This embodiment provides a fan assembly, including the filter screen installation structure described in Embodiment 1, and has all its technical advantages, which will not be repeated here.

Embodiment 3

[0068] This embodiment provides a range hood, which includes the fan assembly described in Embodiment 2, and has all its technical advantages, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com