A kind of supporting equipment and using method of bridge prefabricated hollow slab side form

A technology of support equipment and hollow boards, which is applied in the direction of manufacturing tools, mold fixtures, mold auxiliary parts, etc., can solve the problems of cumbersome construction procedures, wood chips, human body and environmental hazards, and heavy formwork workload, so as to avoid wooden wedges The use of square wood, strong controllability and randomness, and the effect of safe and reliable component structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

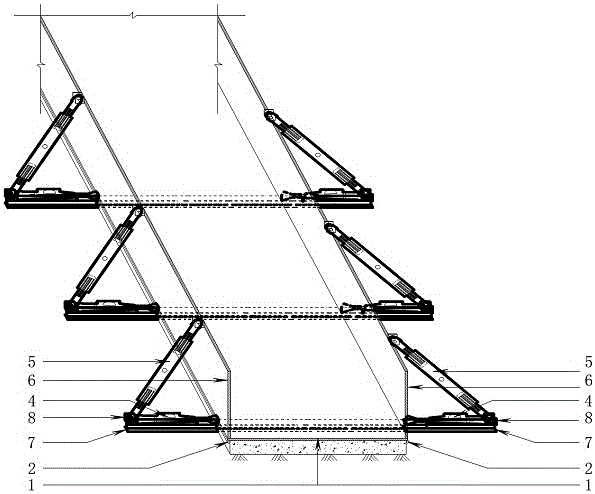

[0023] A kind of supporting equipment and using method about bridge prefabricated hollow slab side formwork, such as figure 1 , 2 , Shown in 3 and 4: it utilizes when pouring the hollow slab prefabricated pedestal 1, after the prefabricated pedestal 1 pre-embeds the fixing part 3, the hollow slab side form 6 is supported by the jack 4 and the adjusting screw 5.

[0024] Such as figure 1 As shown: a sealing pipe 2 is installed on both sides of the longitudinal edge of the hollow plate prefabricated pedestal 1 .

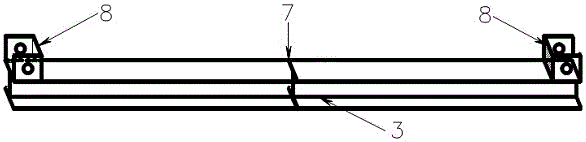

[0025] Such as figure 2 As shown: the embedded fixing part 3 is formed by welding a section of No. 5 small channel steel 8 at both ends of No. 10 I-beam 7 .

[0026] Such as figure 1 , 2 As shown: the pre-embedded fixing part 3 is pre-embedded when pouring the concrete of the prefabricated pedestal 1 of the hollow slab, and is used for supporting the jack 4 and connecting one end of the adjusting lead screw 5 .

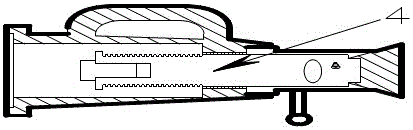

[0027] Such as image 3 Shown: described jack 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com