Full-automatic linear edge grinding machine for glass production

A fully automatic, edger technology, applied in machine tools, grinding frames, and parts of machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of requiring manual assistance, single use, inconvenience, etc. Edge grinding problem, high degree of automation, the effect of simple machine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

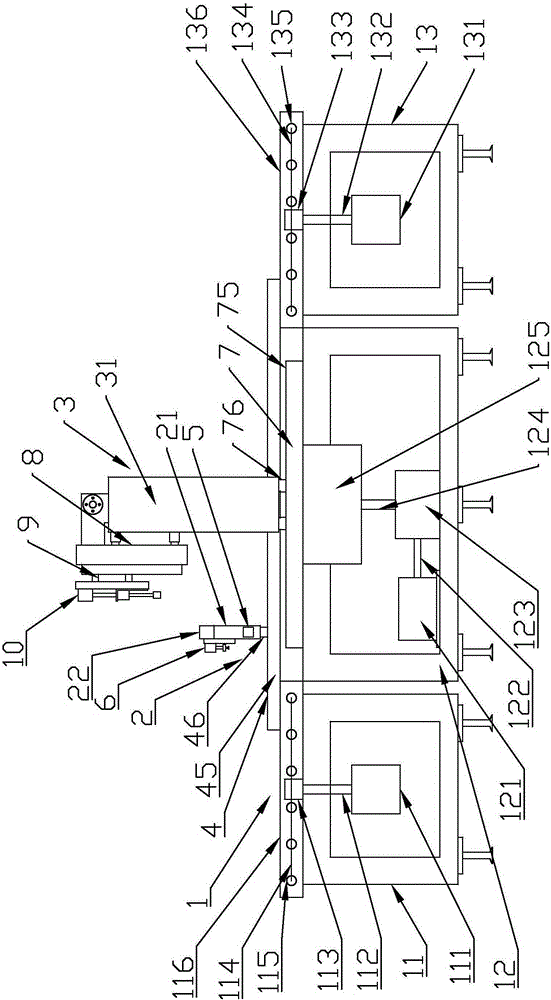

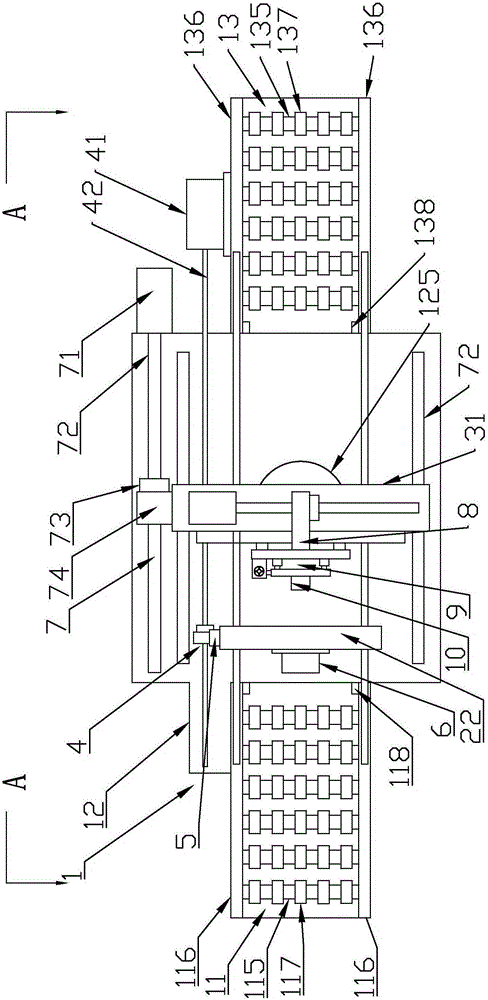

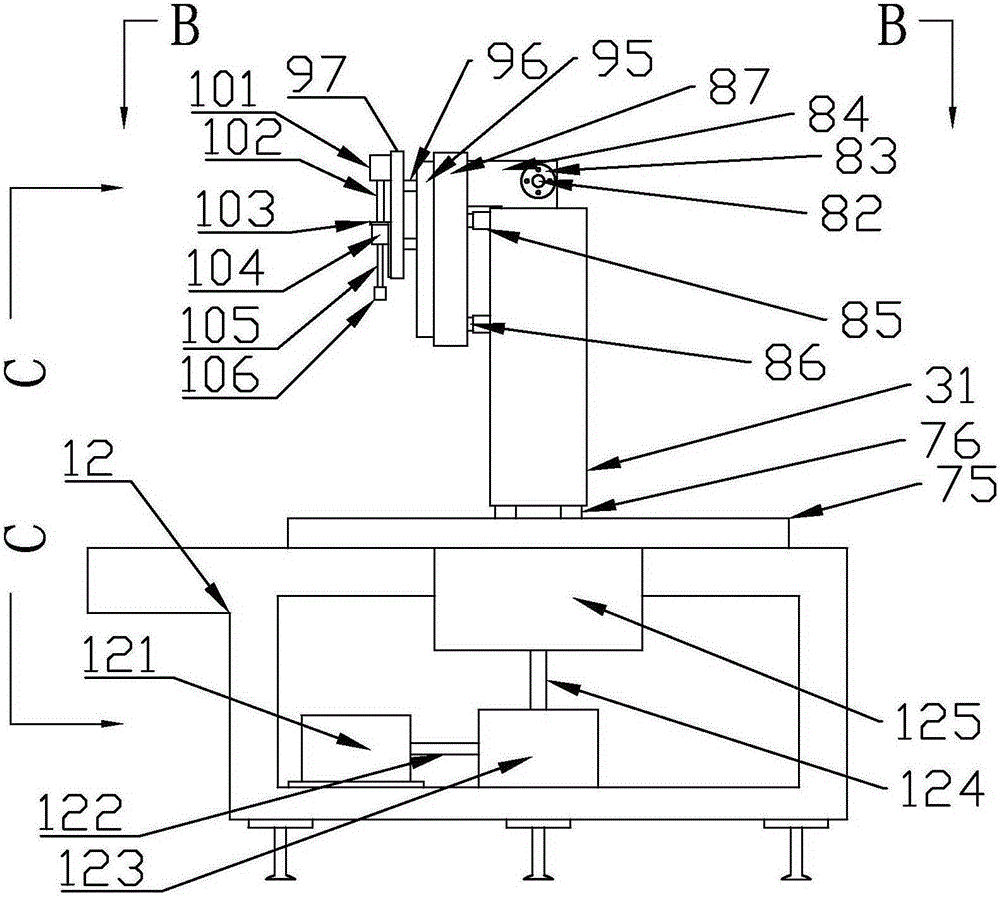

[0031] Such as Figure 1 to Figure 10 Shown, a kind of full-automatic linear edging machine for glass production comprises frame 1, and frame 1 comprises feed frame 11, main frame 12 and discharge frame 13, feed frame 11, main frame 12 and Discharging frame 13 is placed successively from left to right. A feeding device is provided on the feeding frame 11, a discharging device is provided on the discharging frame 13, a transporting manipulator 2 and an edging device 3 are provided on the main frame 12, and an edging workbench is arranged inside the main frame 12 125. The transport manipulator 2 includes an X-direction transport mechanism 4, a Y-direction clamping mechanism 5, and a suction cup mechanism 6. The X-direction transport mechanism 4 is fixedly installed on the main frame 12, and the X-direction transport mechanism 4 is provided with a vertical transport mechanism. Frame 21, the side of vertical material transport frame 21 is fixedly installed with Y direction clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com