Edge grinding device for automobile part machining

A technology for spare parts and edging, which is used in metal processing equipment, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve problems such as low work efficiency, low processing accuracy, poor stability, etc. Precise grinding effect, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

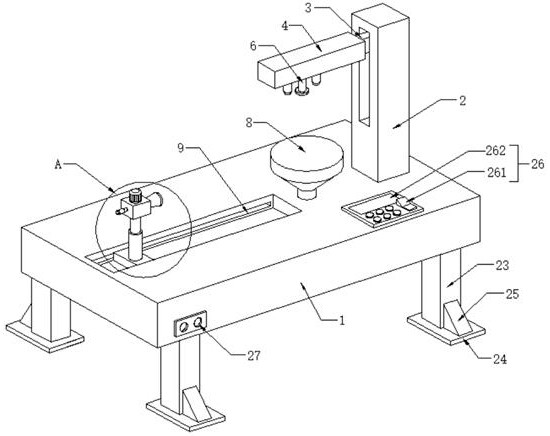

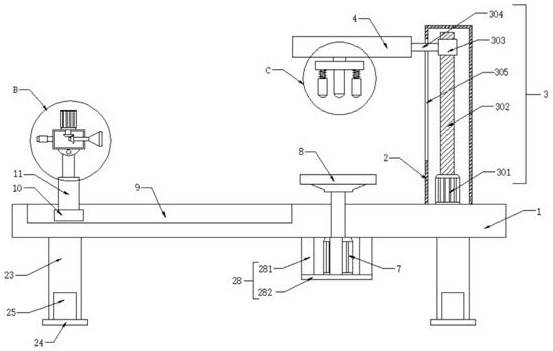

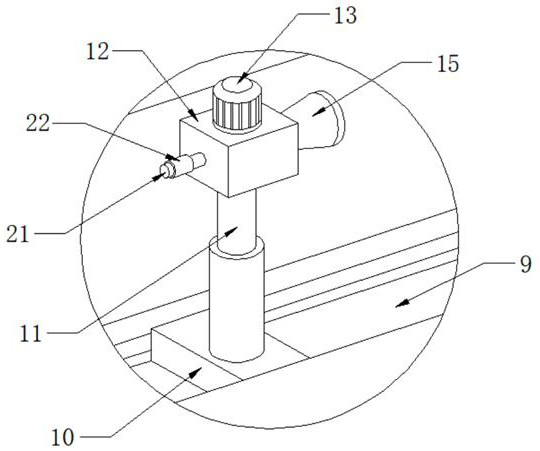

[0032] Such as Figure 1-7 As shown, the present invention provides a kind of edging device for auto parts processing, comprising a base 1, the top of the base 1 is fixedly connected with a mounting column 2, the inside of the mounting column 2 is provided with a lifting device 3, and one side of the lifting device 3 is fixed A horizontal plate 4 is connected, and the bottom end of the horizontal plate 4 is connected to a disk 5 through bearing rotation, the bottom end of the disk 5 is provided with a fixing device 6, the bottom end of the base 1 is installed with a steering gear 7, and the output shaft of the steering gear 7 It runs through the base 1 and is connected with a storage table 8 through transmission, and the storage table 8 is installed correspondingly with the fixing device 6. There is an electric slide rail 9 on the base 1, and a slider 10 is slidably connected to the inner side of the electric slide rail 9. The slider 10 The top is fixedly connected with an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com