Method and apparatus for monitoring safety glass production or controlling a treatment process

A safety glass and glass technology, applied in glass manufacturing equipment, glass transportation equipment, glass tempering, etc., can solve the problems of expensive detectors, poor dimensional accuracy, and inability to provide reliable information on the size of glass sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

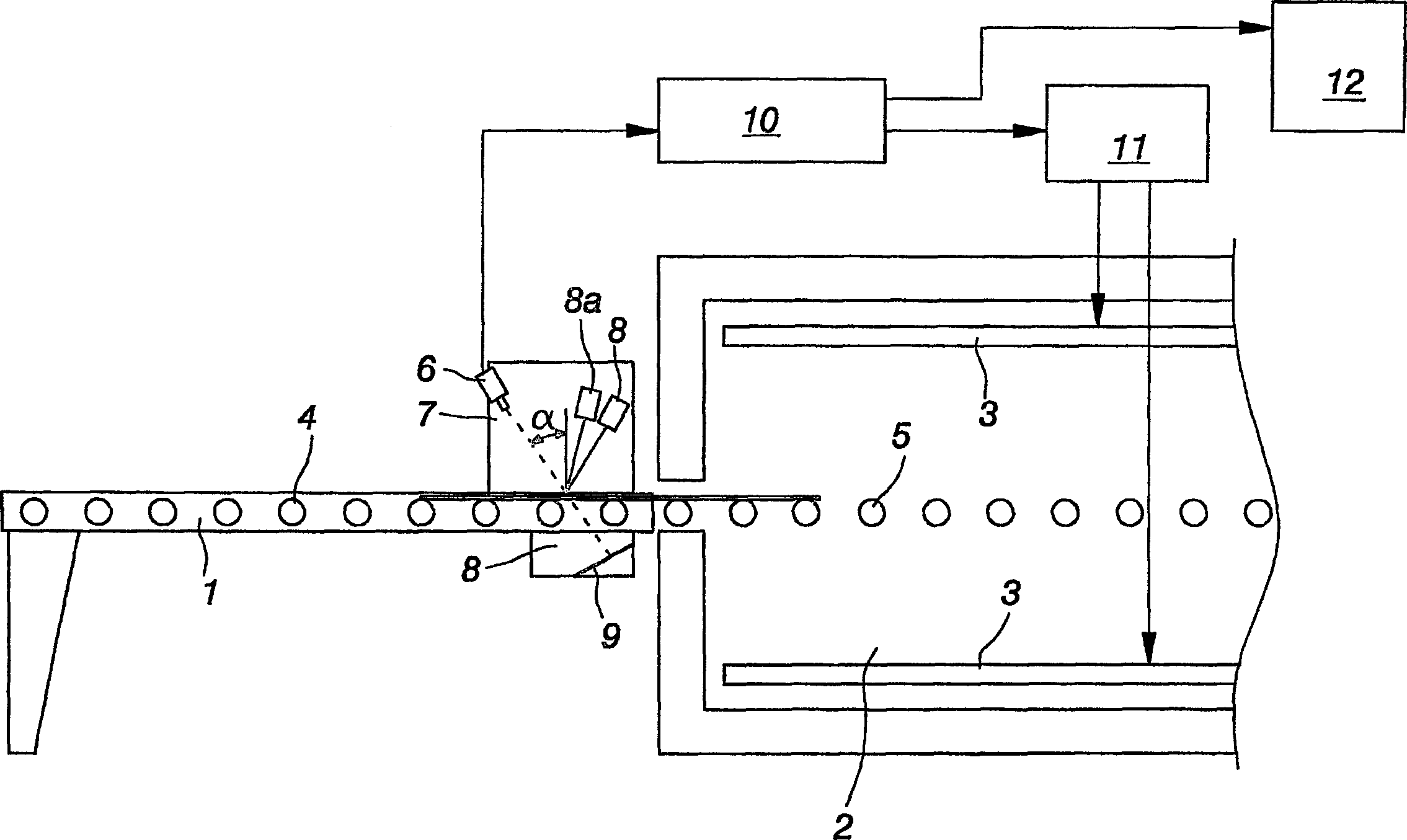

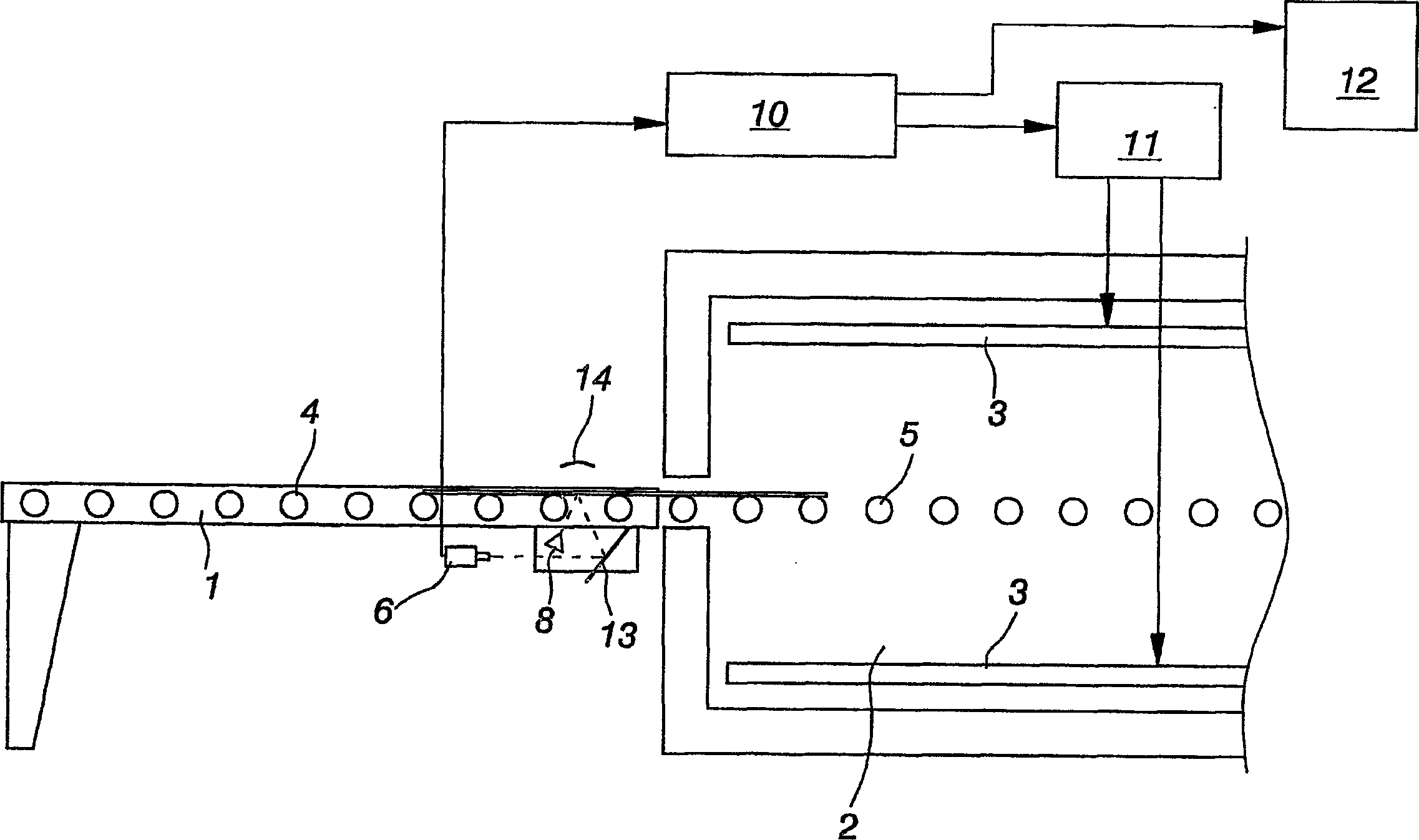

[0018] The flat glass to be tempered, having the desired shape and size, is placed on a conveyor belt consisting of rollers 4 of the loading table 1 , whereby the glass load is conveyed to the conveyor belt of rollers 5 in the furnace 2 . Heating of the glass load takes place, for example, via resistors 3 arranged above and below the conveyor belt 5 . Other types of known heat sources may also be used. One example that may be mentioned is the convection blower. The heating element 3 may comprise both a radiant heating element and a convective heating element as a combination.

[0019] For heating control and other purposes described subsequently, it is advantageous to have as comprehensive a knowledge of the information indicative of the loading, in particular the loading rate, position, shape and size of the glass panels. Thus, in figure 1 In the embodiment shown, towards the downstream end of the loading table 1, a short section of the conveyor belt is enclosed within a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com