Environment-friendly flint optical glass and optical element

A technology of optical glass and optical components, which is applied in the field of environmentally friendly flint optical glass and optical components, can solve the problems of unsatisfactory glass chroma quality and unsatisfactory bubble quality, and achieve the effect of low glass production difficulty, ideal bubbles, and favorable bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

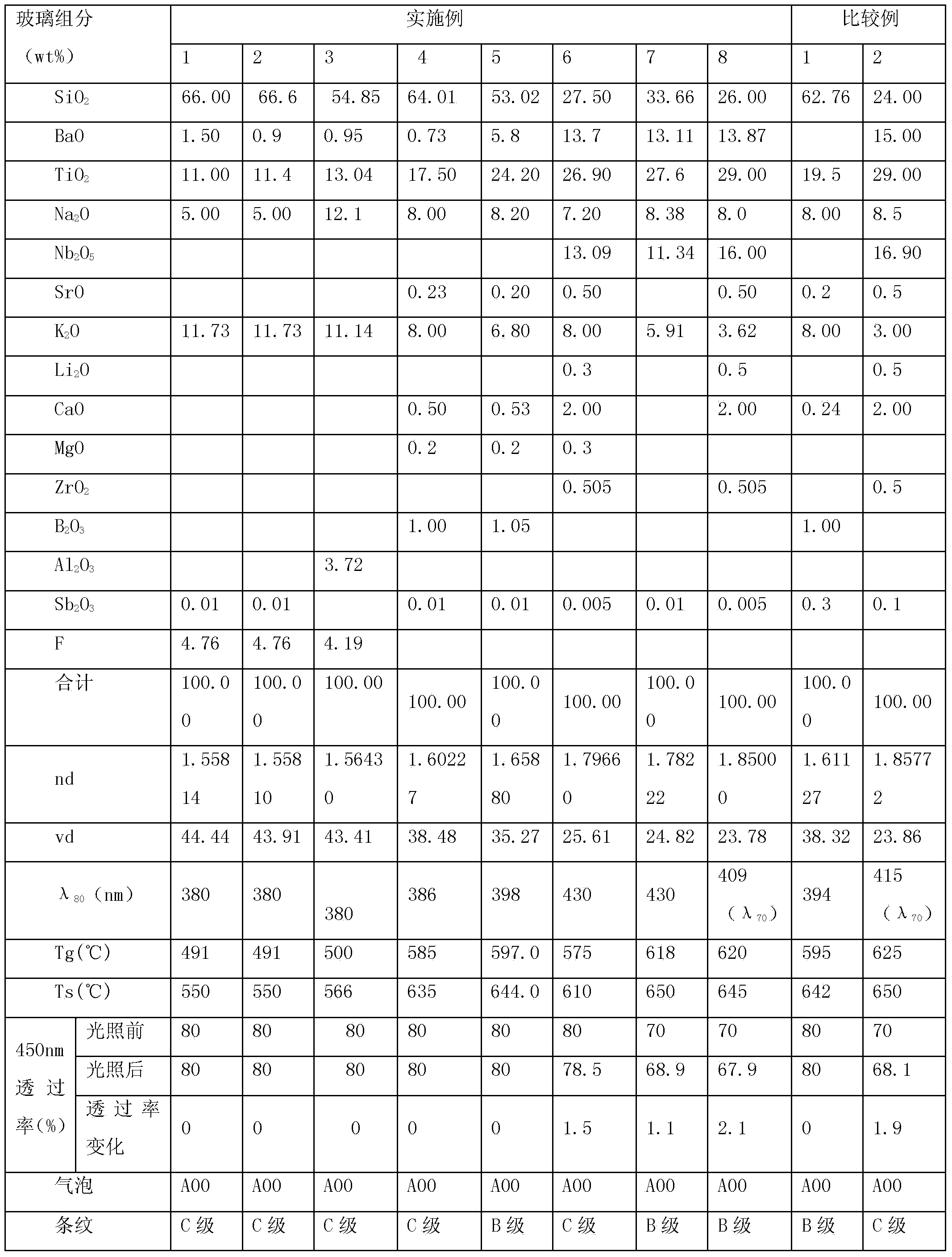

Examples

Embodiment Construction

[0026] The various components of the optical glass of the present invention will be described below, and unless otherwise specified, the ratios of the content of each component are expressed in % by weight.

[0027] Sb 2 o 3 It has the effect of eliminating bubbles in the glass of environmentally friendly flint and environmentally friendly heavy flint, but at the same time it will also reduce the quality of glass chroma. Increase Sb in glass formulation 2 o 3 content, the quality of glass chroma will decrease; reduce Sb in glass formulation 2 o 3 Content, glass color quality can be improved. In order to ensure glass bubbles and chromaticity at the same time, it is necessary to control the introduction of Sb 2 o 3 content. The study found that a small amount of Sb 2 o 3 with and without Sb 2 o 3 Comparatively, the glass transmittance has no change, therefore, the Sb of the present invention 2 o 3 The content is preferably 0.1% as the upper limit, more preferably 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com