Glass producing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

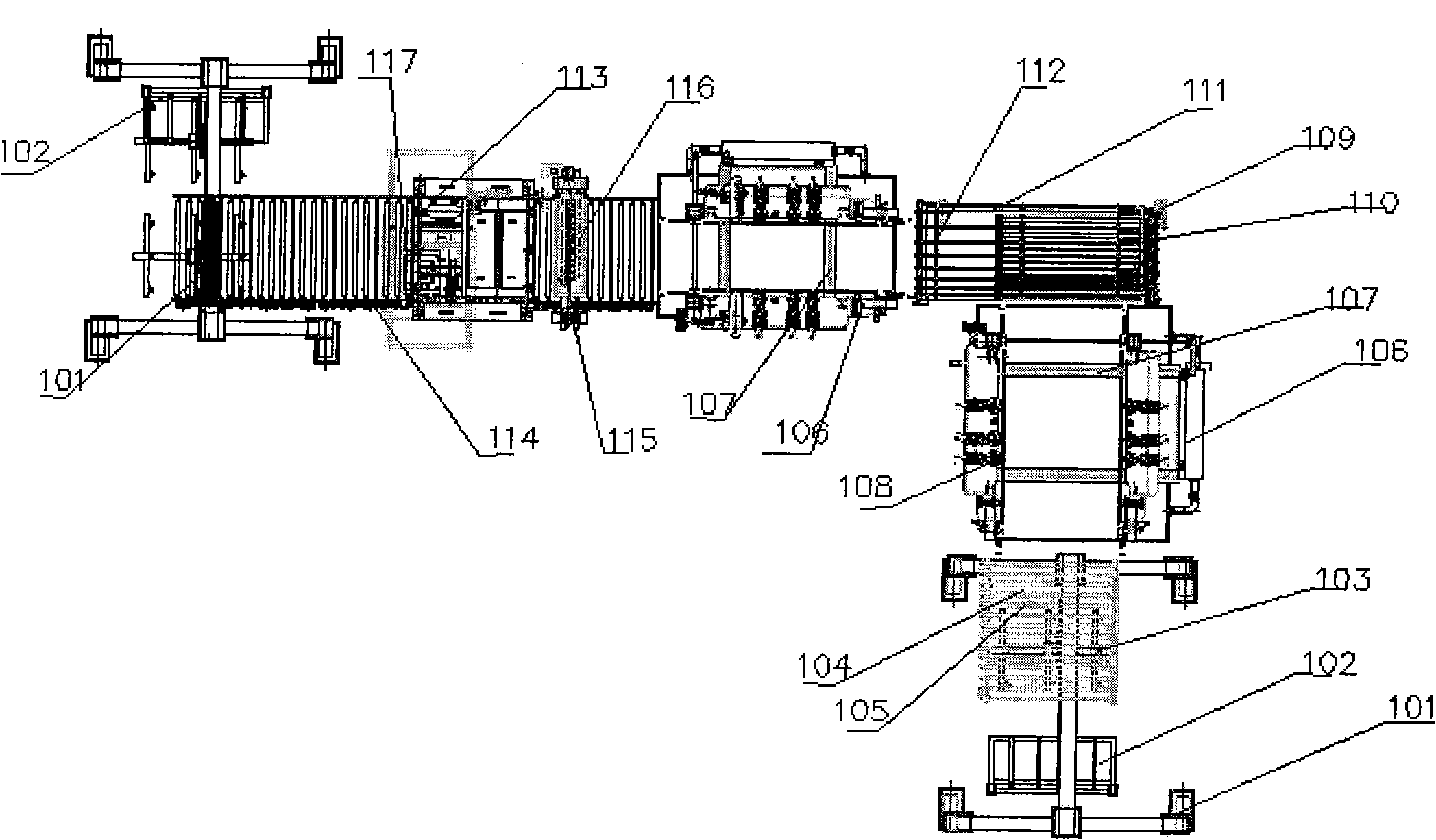

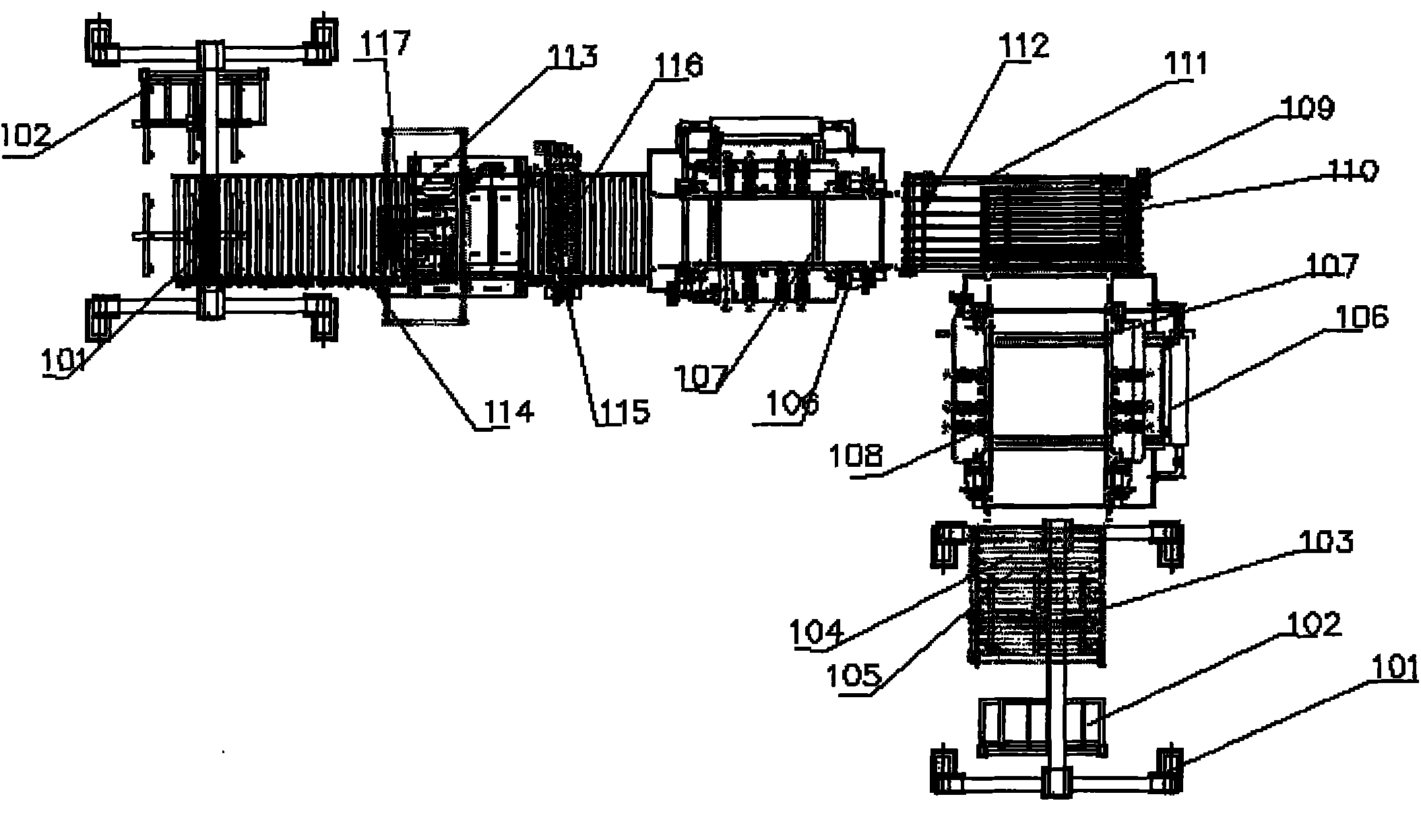

Embodiment 1

[0020] Example 1 as figure 1 As shown, a glass production system, which consists of 101-automatic loading and unloading machine; 102-glass storage rack; 103-automatic loading and unloading machine suction cup; 104-line transmission platform; 105-line roller; ;107-double-sided edging machine roller; 108-glass grinding device; 109-right angle corner controller; 110-corner table; 111-right angle turntable; 112-right angle turntable roller; 113-glass cleaning table; 114-glass cleaning table roller; 115-glass cleaning device; 116-high pressure washing faucet; 117-glass drying device.

[0021] When the corner type assembly line is working, the automatic loading and unloading machine 101 works, and the automatic loading and unloading machine suction cup 103 on the automatic loading and unloading machine sucks up the glass to be processed from the glass storage rack 102 and transfers it to the assembly line transmission platform 104, which is the assembly line transmission platform T...

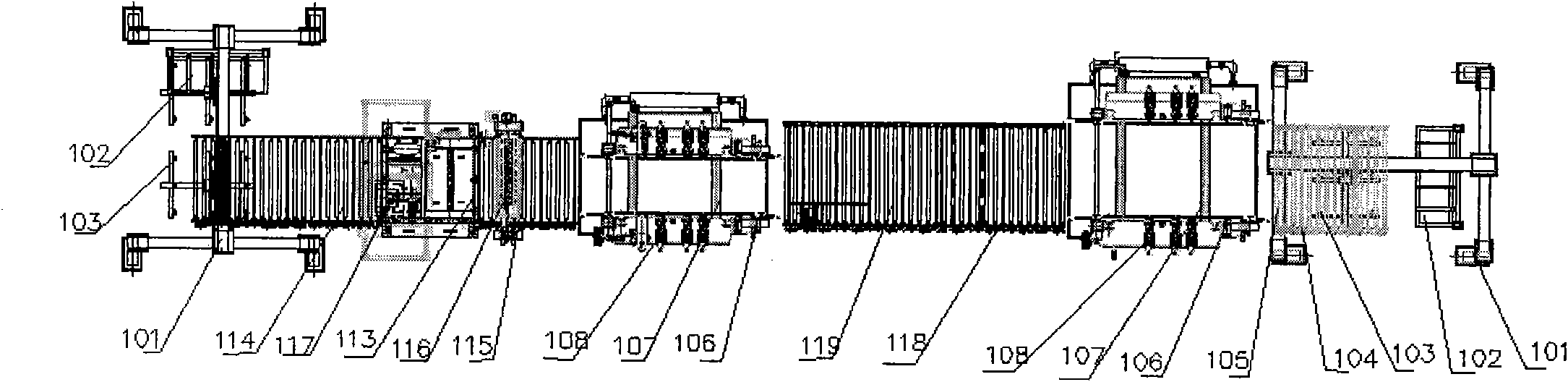

Embodiment 2

[0022] Example 2, such as figure 2 As shown, a glass production system consists of 101-automatic loading and unloading machine; 102-glass storage rack; 103-automatic loading and unloading machine suction cup; 104-line transmission platform; 105-line roller; 107-Bilateral edging machine roller; 108-Glass grinding device; 112-Right-angle rotary table roller; 113-Glass cleaning table; 114-Glass cleaning table roller; 115-Glass cleaning device; 116-High pressure washing faucet; 117-glass drying device; 118-linear transmission platform; 119-glass corner platform.

[0023] When the linear assembly line works, the automatic loading and unloading machine works, and the automatic loading and unloading suction cup 103 on the automatic loading and unloading machine 101 sucks up the glass to be processed from the glass storage rack 102 and transfers it to the assembly line transmission platform 104, and the assembly line transmission platform rolls The shaft 105 rotates and the glass mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com