Glass plate width detection system based on machine vision

A machine vision and detection system technology, applied in instruments, measuring devices, optical devices, etc., to achieve high real-time and precision, high resolution, and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

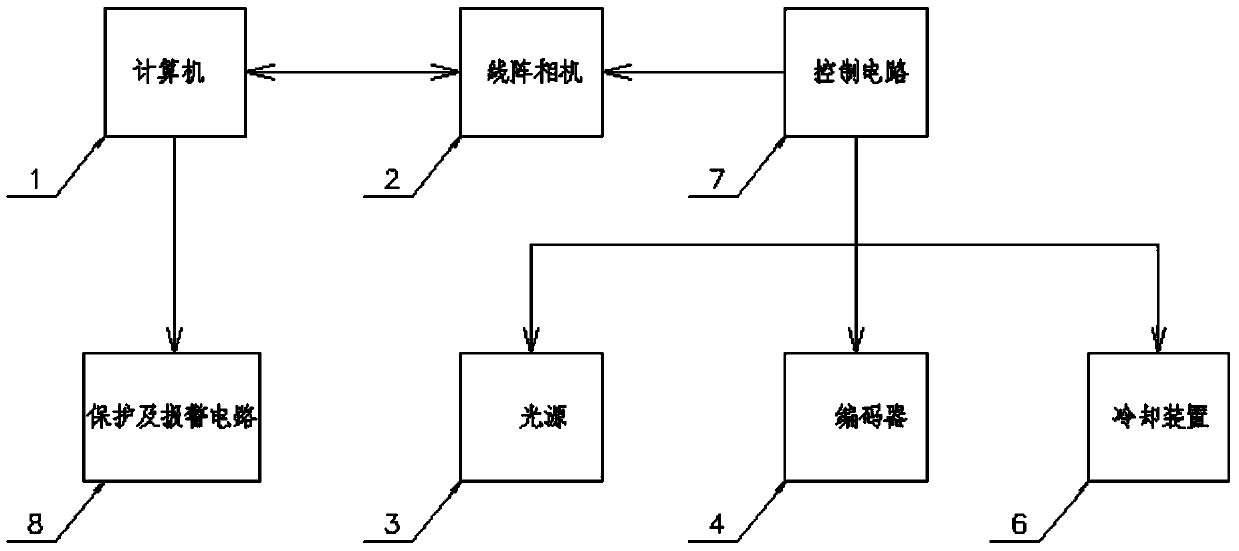

[0032] Such as figure 1 As shown, the computer drives the control circuit to control the cooling device, light source, and encoder. The cooling device is used to cool down the heating equipment such as the camera, the light source is used for graphic imaging, the encoder drives the camera to collect images, and then the computer reads the image information of the glass from the line array camera to process the image information.

Embodiment 2

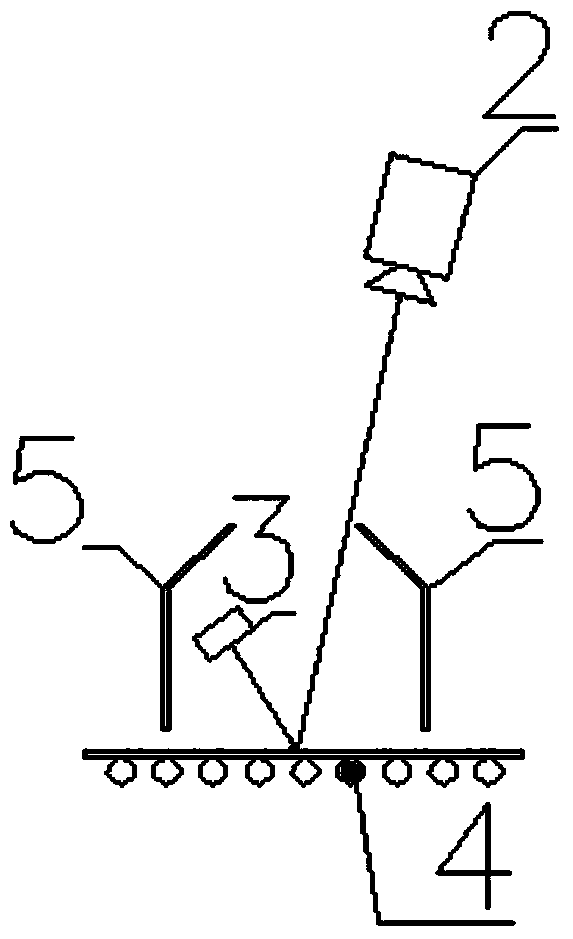

[0034] Such as figure 2 as shown, figure 2 The middle light source is a white LED strip light source. When there is glass below it, it will reflect and image on the glass surface. The line scan camera obtains the data of the glass plate by collecting the imaging area of the light source. When no glass plate passes through or the glass plate has When it breaks, the image obtained by the line array camera is a full-scale low gray value image or an incomplete high gray value image; the encoder collects the roller speed pulse signal in real time, so that the line array camera can adjust the acquisition frequency in real time to ensure the authenticity of the image , will not stretch or compress, and can guarantee the accuracy of the measurement data. The line-scan camera is located at a certain height above the glass, and the light source and the line-scan camera are installed above the glass at a certain angle, so that the projection on the glass can be captured by the line-...

Embodiment 3

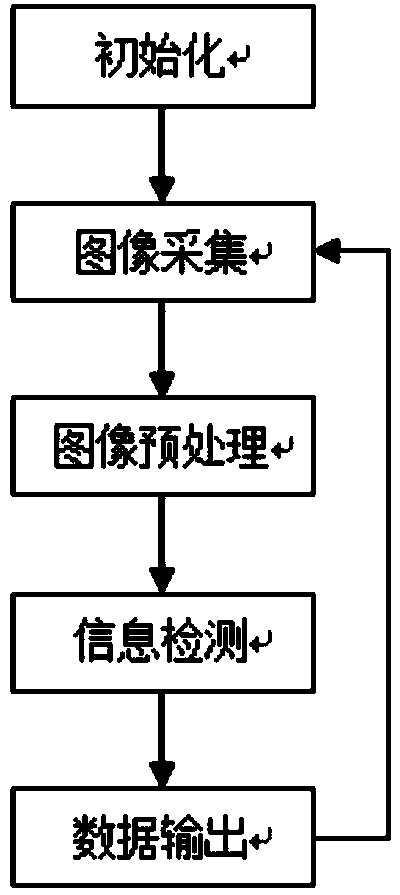

[0036] Such as image 3 As shown in , the computer program is initialized, and the line scan camera collects an image through the encoder signal. Perform image preprocessing such as smoothing and binarization on the image, and then detect the preprocessed image to obtain data such as the width of the glass in the image, the position of the edge of the sheet, the angle between the edge of the sheet and the direction of the glass, and the information of the broken sheet. And output the data information of the glass to the output device or send it to a third-party device, and then re-collect the image to start a new inspection.

[0037] The system has protection and alarm circuits to deal with some system failures, especially the failures that may cause damage to the equipment. The hood is used to block the ambient light and reduce the interference of the ambient light on the image.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com