Method of manipulator stacking system for glass

A technology of manipulators and glass, which is applied in the stacking of objects, conveyor objects, and unstacking of objects. It can solve the problems of not very high stacking uniformity and large position errors, and achieve shortened stacking cycle and operation. Faster, more precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

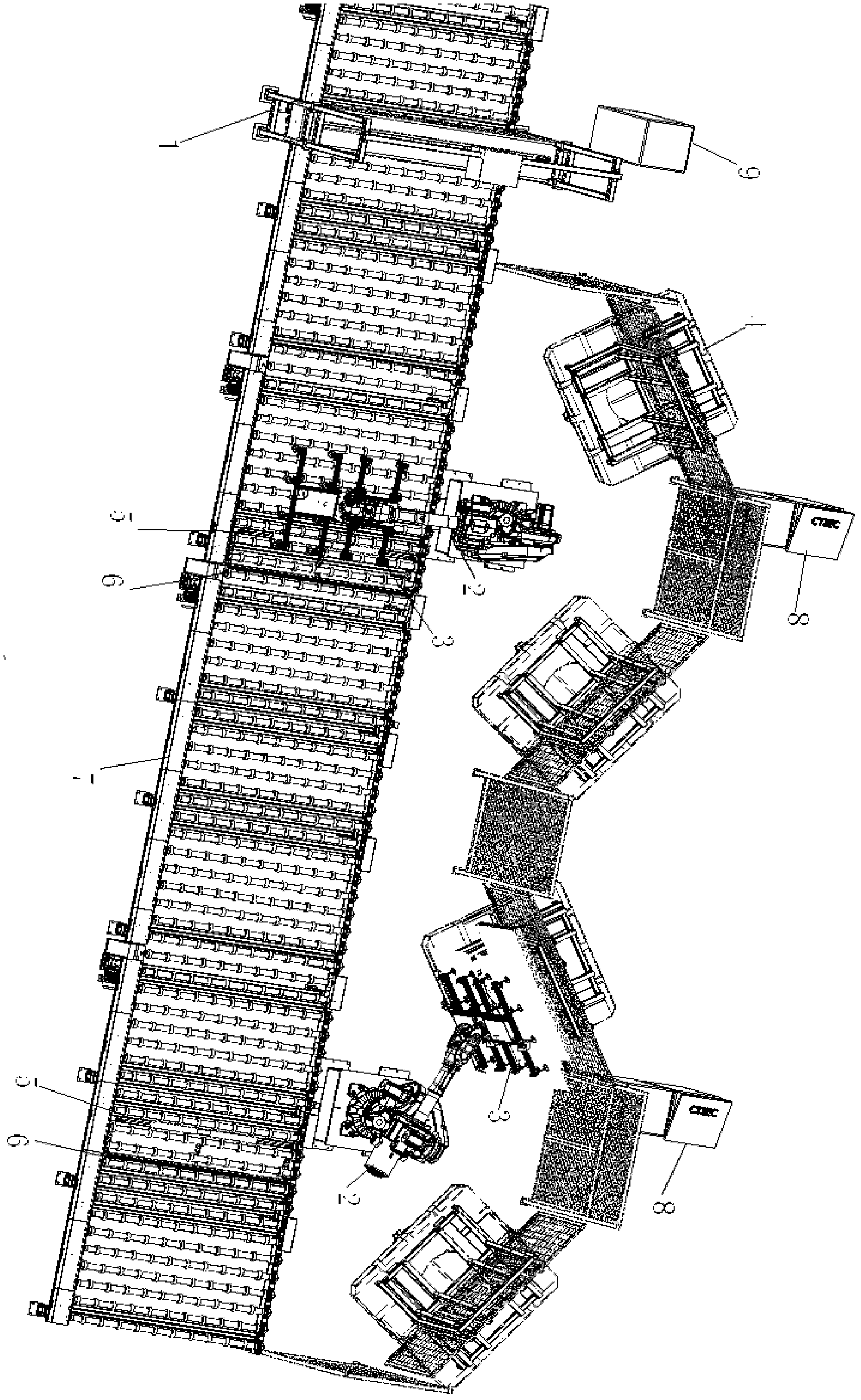

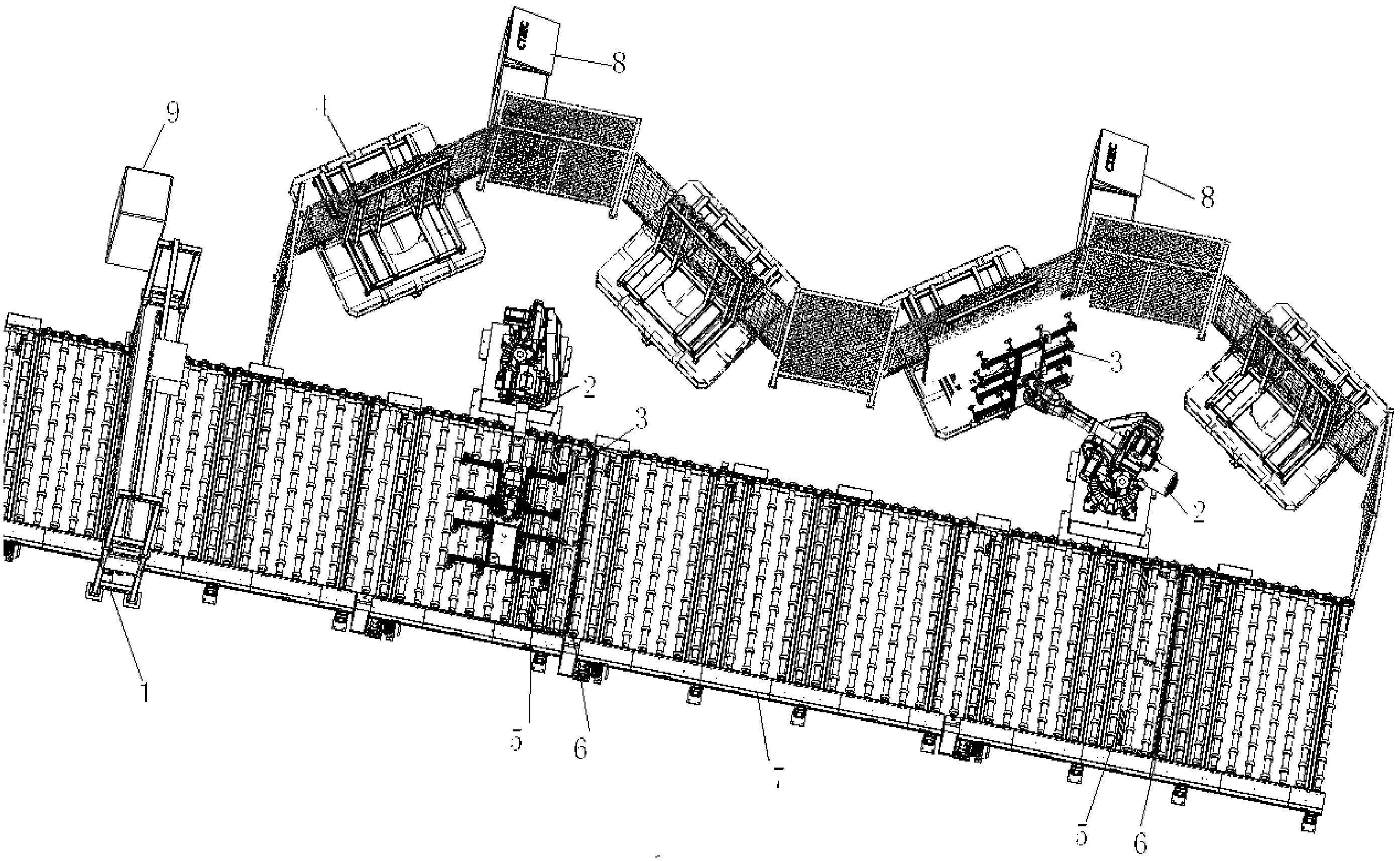

[0022] The present invention will be further described below with reference to the accompanying drawings.

[0023] As shown in the figure, the present invention is located at the end of the cold end, and mainly includes a visual inspection system 1, a manipulator 2, a vacuum suction cup gripper 3, a rotating platform 4, an edge measuring device 5, an edge retaining mechanism 6, a conveying roller table 7, and stand-alone electrical control. Cabinet 8, management system 9.

[0024] Visual inspection system 1 includes computer, signal collector, encoder and linear array photoelectric sensor group, LED light source, installation and adjustment bracket, etc. The computer connects the encoder and linear array photoelectric sensor group respectively through the signal collector. The linear array photoelectric sensor group is parallel to the moving surface of the roller table and perpendicular to the moving direction of the glass. The encoder is installed on the roller table. The LED...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com