Ultrathin toughened glass production line and production method

A tempered glass and ultra-thin glass technology, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as increased energy consumption, slow flow rate, and increased glass temperature, so as to reduce energy consumption loss and achieve stable and accurate transmission , Strong cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

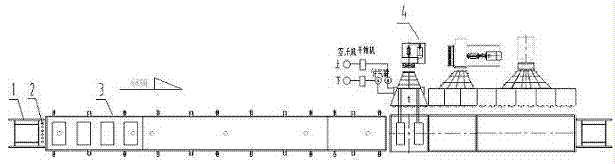

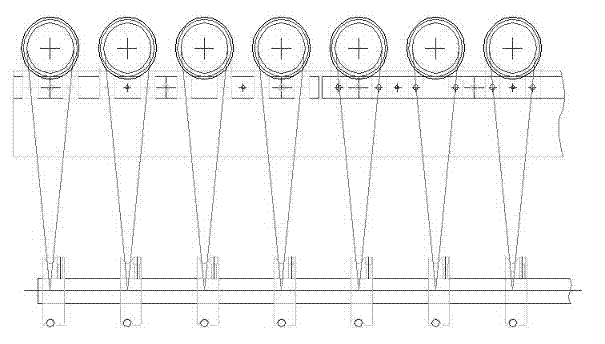

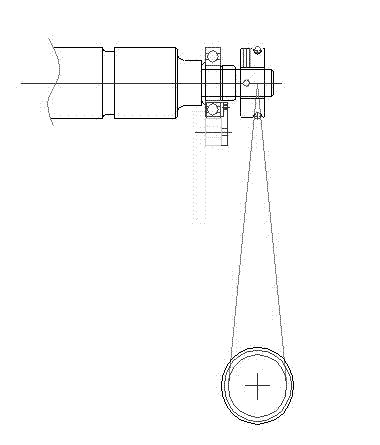

[0025] Embodiment 1: with reference to attached Figure 1-7 . A production line for ultra-thin tempered glass, comprising a glass conveying mechanism 1, a glass dimension measuring device 2, a heating furnace body 3, a quenching air grid section 4 and a program controller, a plurality of driving wheels 102 in the glass conveying mechanism 1, etc. On the driving shaft 103 with fixed spacing, one end of the plurality of rollers 101 located above the driving shaft 103 has a driven wheel 105 respectively, and the wheel surface of the driven wheel 105 is perpendicular to the wheel surface of the driving wheel 102, and the 8-shaped transmission belt 104 is sleeved on the driving wheel 102 On the driven wheel 103 and drive a plurality of driving wheels 102 through the drive shaft 103 to drive a plurality of rollers 101 matched therewith to rotate synchronously; a plurality of photoelectric cells in the glass dimension measuring device 2 are horizontally densely distributed on the ent...

Embodiment 2

[0028] Embodiment 2: with reference to attached diagram 2-1 with 2-2 . On the basis of Embodiment 1, the driving wheel 102 and the driven wheel 105 in the glass conveying mechanism 1 are single-groove belt transmission wheels, and the single-groove belt transmission uses an 8-shaped transmission belt for power transmission between the driving wheel and the driven wheel.

Embodiment 3

[0029] Embodiment 3: with reference to attached Figure 2-3 with 2-4 . On the basis of Embodiment 1, the driving wheel 102 and the driven wheel 105 in the glass conveying mechanism 1 are double-groove belt transmission wheels, and two 8-shaped transmission belts are used for power transmission between the driving wheel and the driven wheel. transfer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com