Tempered glass manufacturing technique

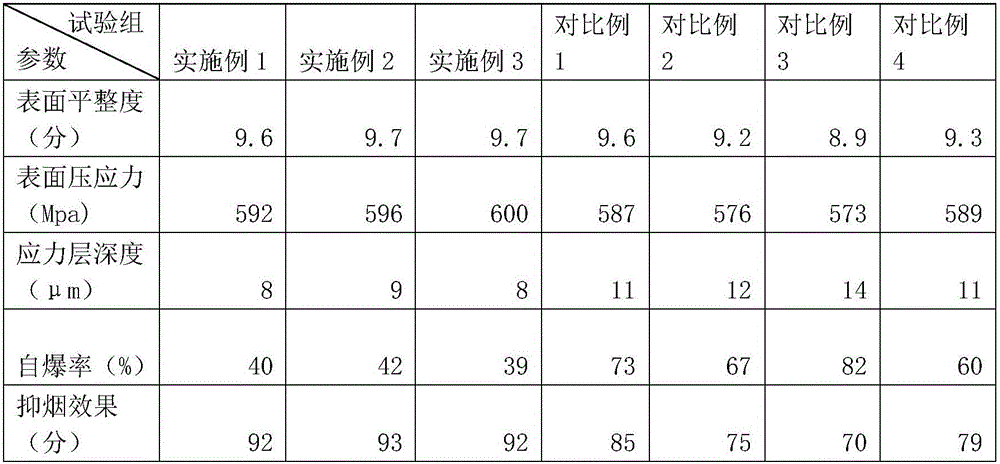

A production process and tempered glass technology, applied in glass production, glass tempering, glass manufacturing equipment, etc., can solve the problems of easy self-explosion of tempered glass and reducing the self-explosion rate of tempered glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

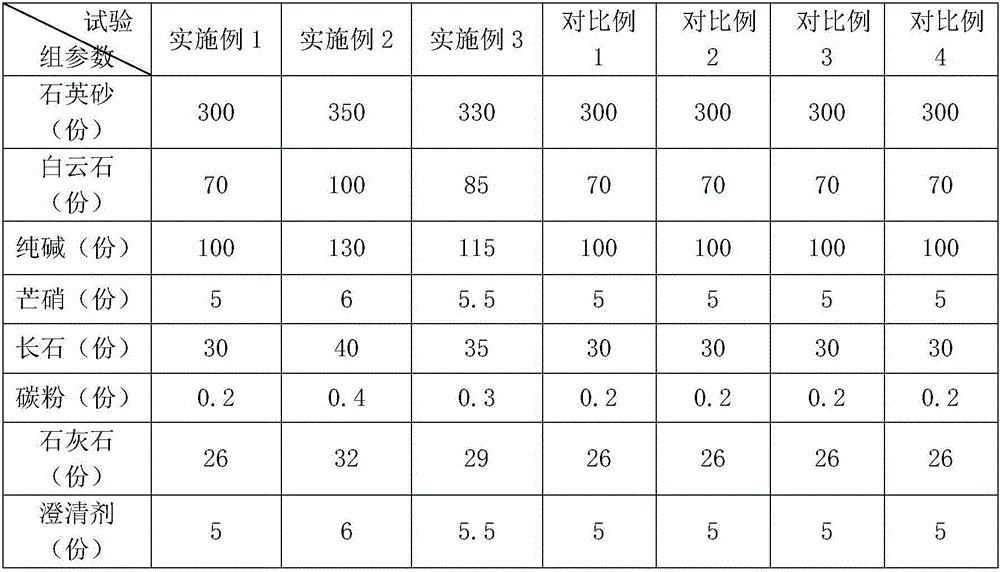

[0025] This embodiment discloses a production process for tempered glass, including the following processing steps:

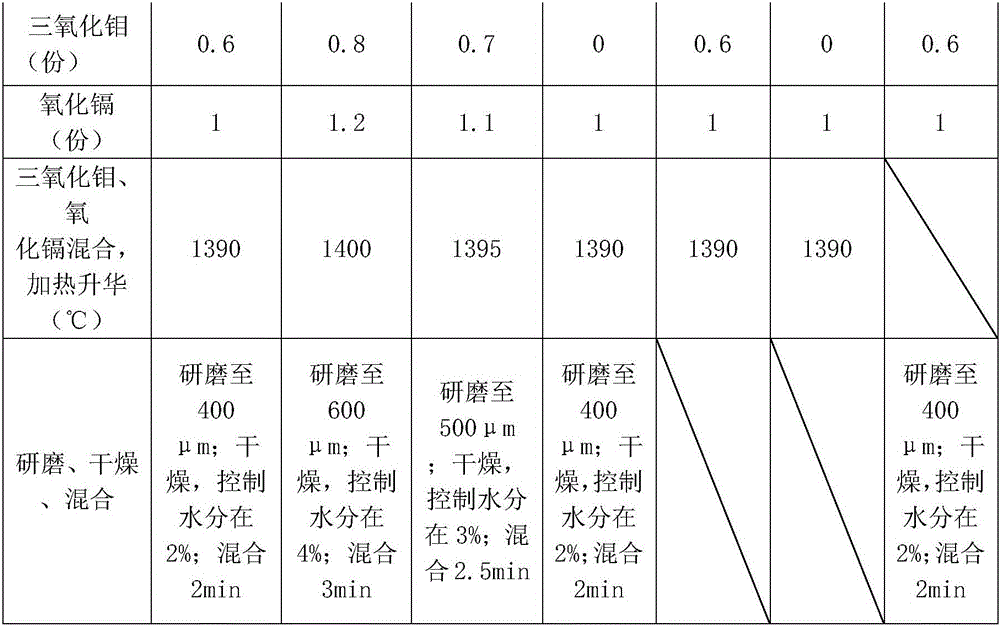

[0026] (1) Ingredients: 300 parts of quartz sand, 26 parts of limestone, 70 parts of dolomite, 100 parts of soda ash, 5 parts of Glauber's salt, 30 parts of feldspar, 0.2 parts of carbon powder, 5 parts of clarifier, trioxide 0.6 parts of molybdenum and 1 part of cadmium oxide; the clarifying agent is used in combination with antimony dioxide powder and white arsenic in a mass-number ratio of 10-14:1;

[0027] (2) Grinding, drying and mixing: Grind the quartz sand, limestone, soda ash, Glauber's salt, feldspar, carbon powder and clarifying agent in step (1) to 400-600 μm, put the ground raw materials into the mixer and mix 2 -3min; During the mixing process, heat the molybdenum trioxide and cadmium oxide after mixing. Inside the machine; dry the mixed powder and keep the water content at 2-4%;

[0028] (3) Melting: heating the material obtained in step (2) in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com