Vacuum glass supporting point distribution method and system

A technology of vacuum glass and support points, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of high playback error rate, high consumption cost, and low efficiency, and achieve good expansion rate and layout High success rate and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

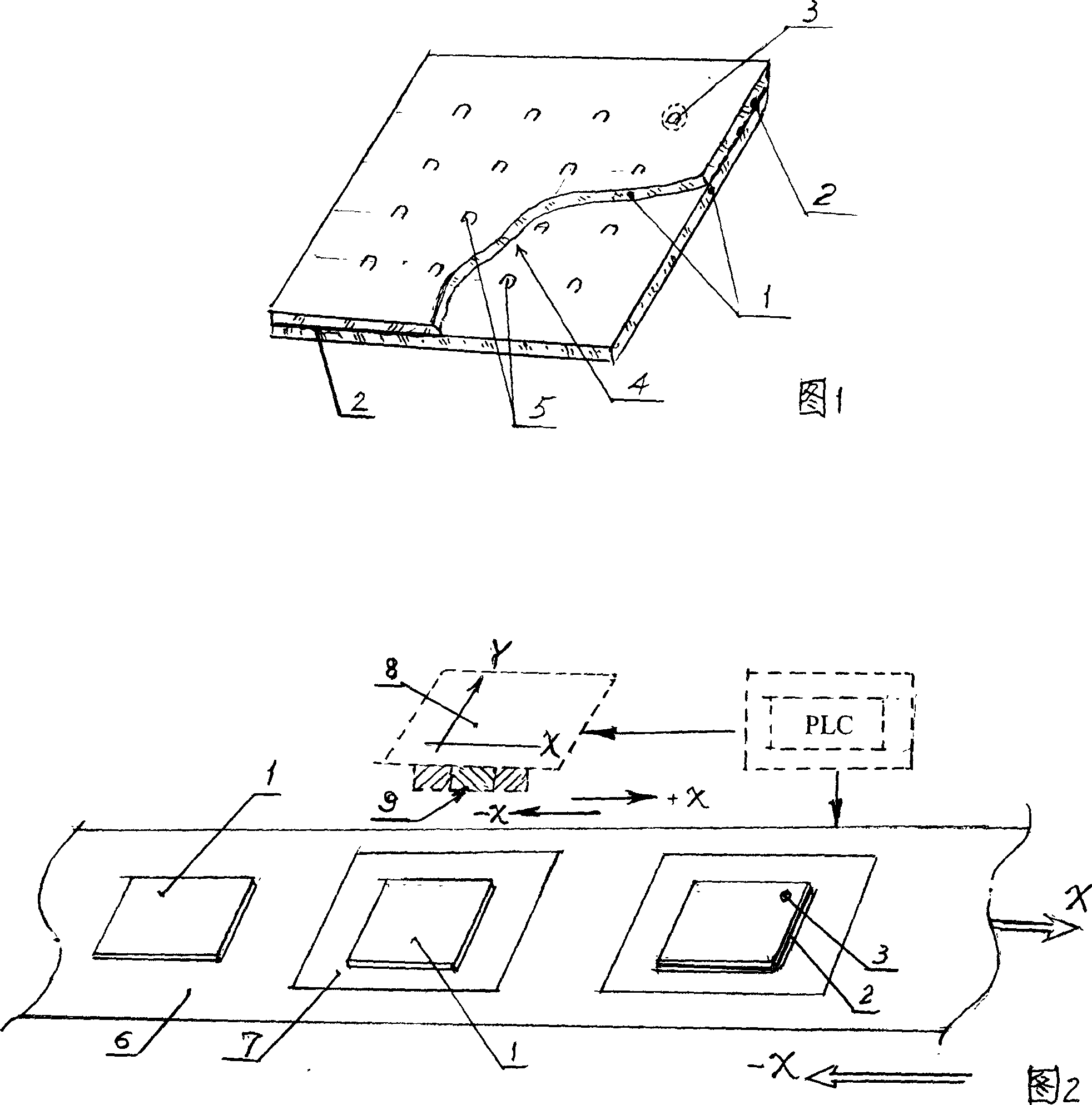

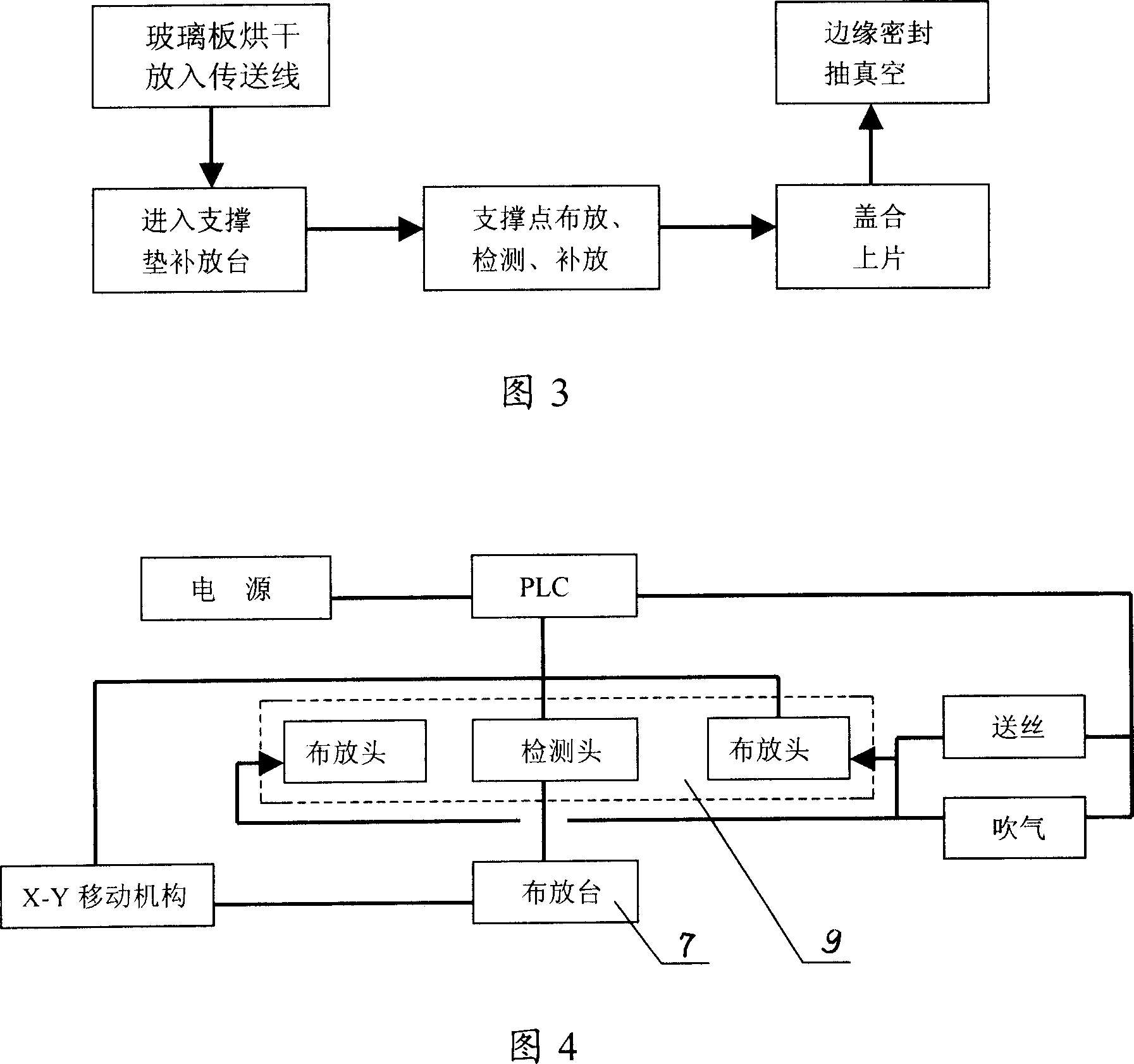

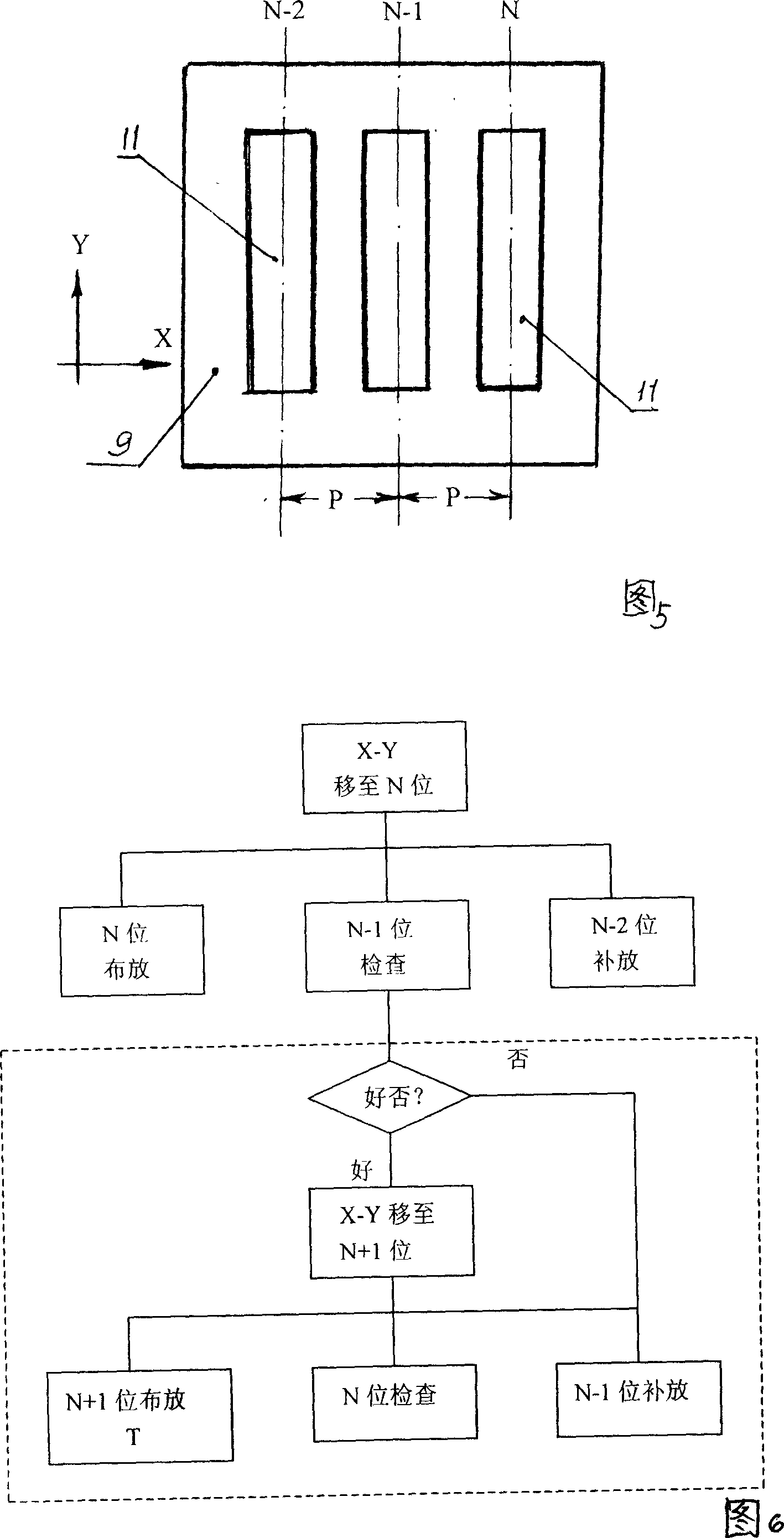

[0021] Referring to Figure 1, it shows a schematic diagram of the vacuum glass shape. In the figure, 1 indicates the upper and lower glass plates, 2 is the vacuum solder used for sealing around the glass plate, and there is a vacuum exhaust hole 3 on the upper glass plate, between the two glass plates The vacuum space is 4, which contains a series of uniformly arranged support points 5. Referring to Fig. 2, it shows the operation diagram of vacuum glass manufacturing, in which the glass plate 1 after cleaning and drying is sent into the transmission mechanism 6, and the distribution table 7 is arranged on the transmission line, driven by the X-Y stepping motor moving mechanism 8 The deployment inspection component 9 will be aligned with the glass plate 1 to be deployed on the deployment table 7, and the support points will be deployed. After the entire support point is deployed, it will enter the cover and sheet loading station. The entire operating system is controlled by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com