Patents

Literature

34results about How to "Eliminate sharp corners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

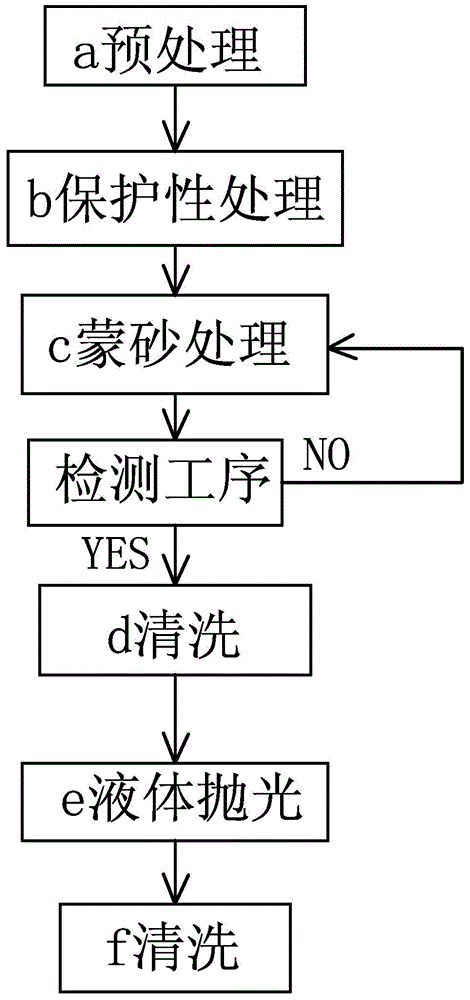

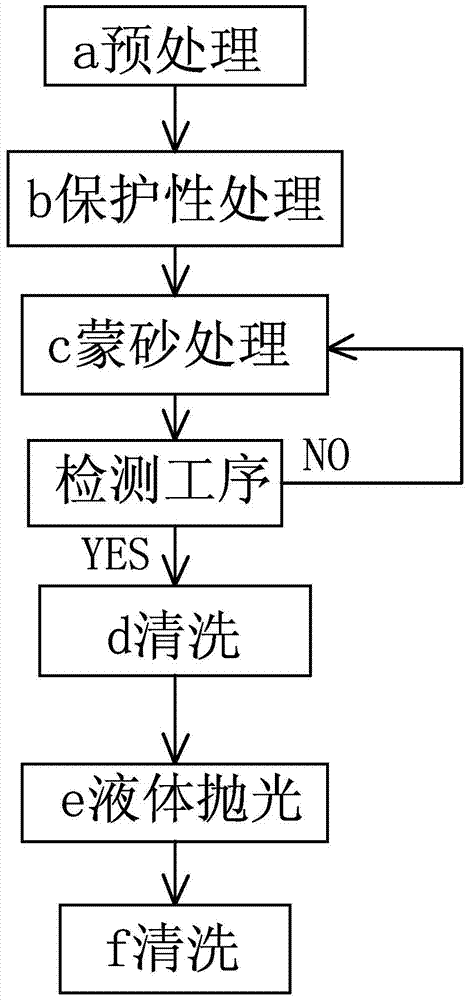

Anti-dazzle processing method for electronic product glass display screen

ActiveCN104829140AEliminate sharp cornersGood optical performanceFlexible article cleaningCleaning using toolsMegasonic cleaningEngineering

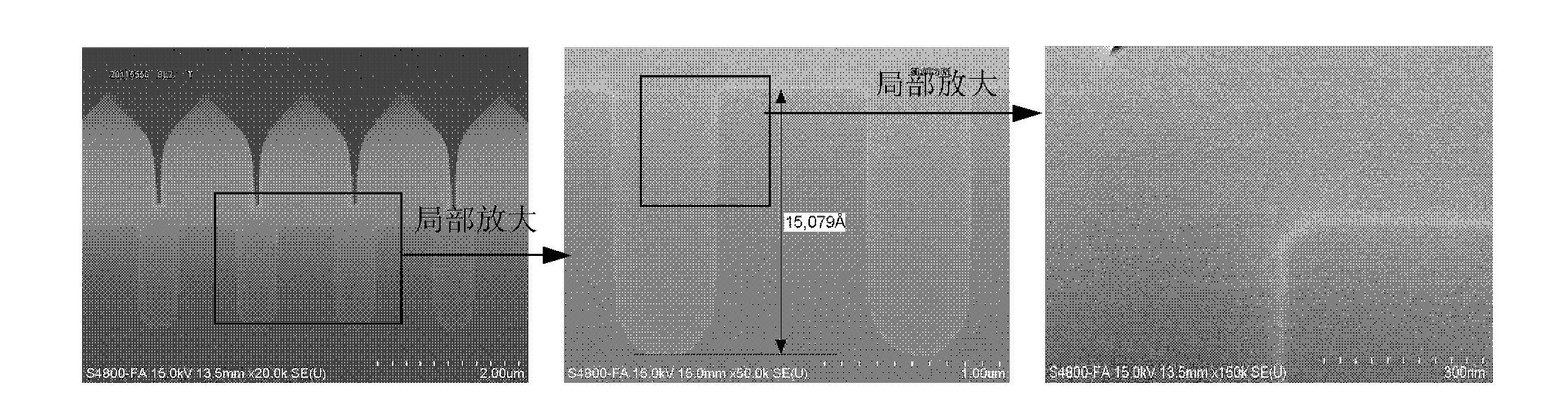

The invention provides an anti-dazzle processing method for an electronic product glass display screen and belongs to the technical field of display screen processing technology. The anti-dazzle processing method includes rinsing and dedusting the glass display screen in a rinsing tank and subjecting the rinsed and dedusted glass display screen to ultrasonic cleaning in an ultrasonic cleaner; sticking corrosion-resistant plastic protective films on four side faces and the back face of the glass display screen; heating frosting liquid to 20-26 DEG C, and soaking the glass display screen in the heated frosting liquid for 60-120 seconds; removing the protective films on the glass display screen; filling a jetting machine with a polishing solution, fixing the glass display screen, and jetting the polishing solution to the front face of the glass display screen through a spray head of the jetting machine for 180-300 seconds. The anti-dazzle processing method for the electronic product glass display screen has the advantages that the anti-dazzle processing method solves the technical problems of poor surface quality, bad hand feeling, weak anti-dazzle capability and the like of anti-dazzle glass manufactured by an existing anti-dazzle processing method for the display screen; microcosmic sharp corners are eliminated by means of adopting a unique high-pressure jetting and polishing mode, so that anti-dazzle capability is improved.

Owner:ZHEJIANG XINGXING TECH CO LTD

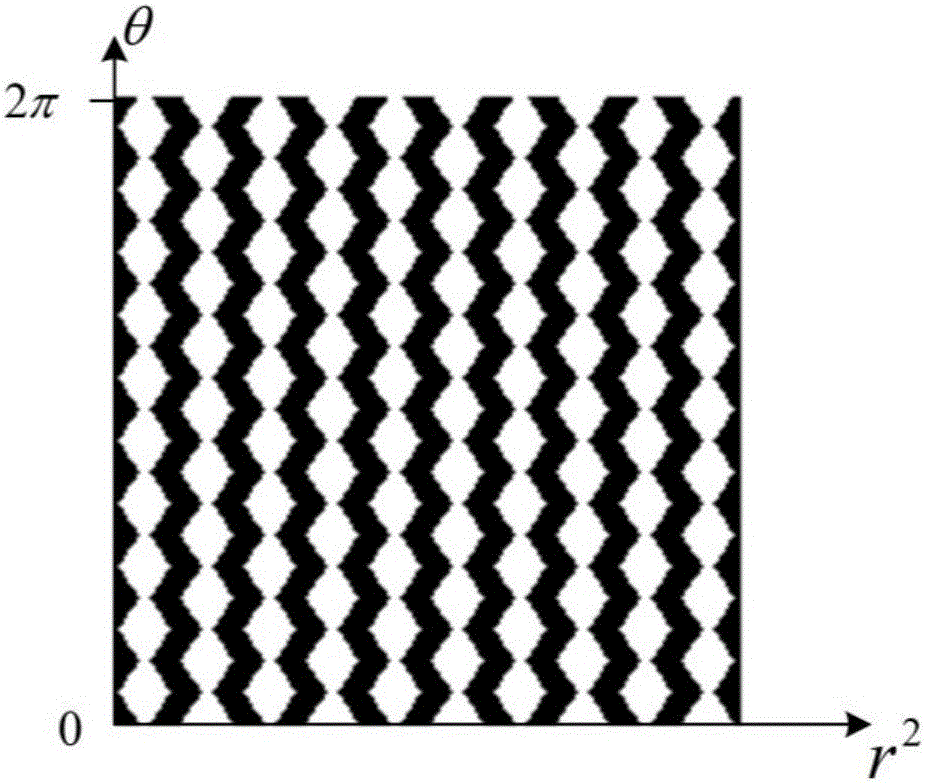

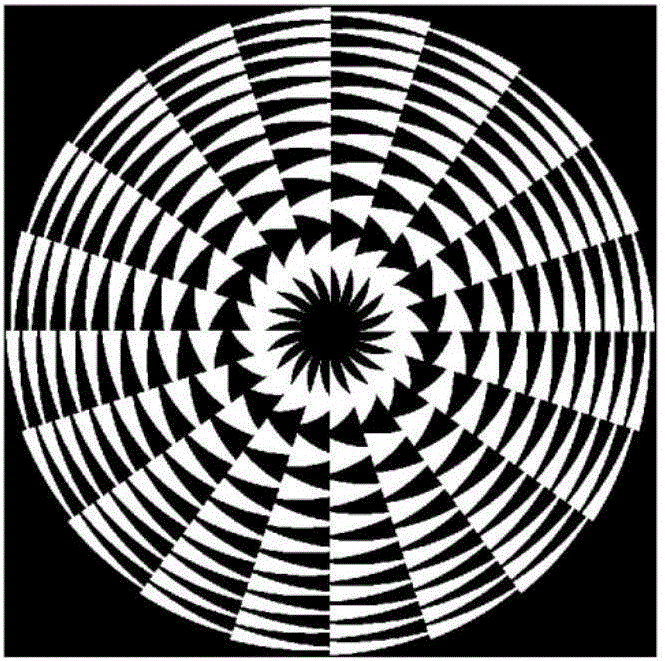

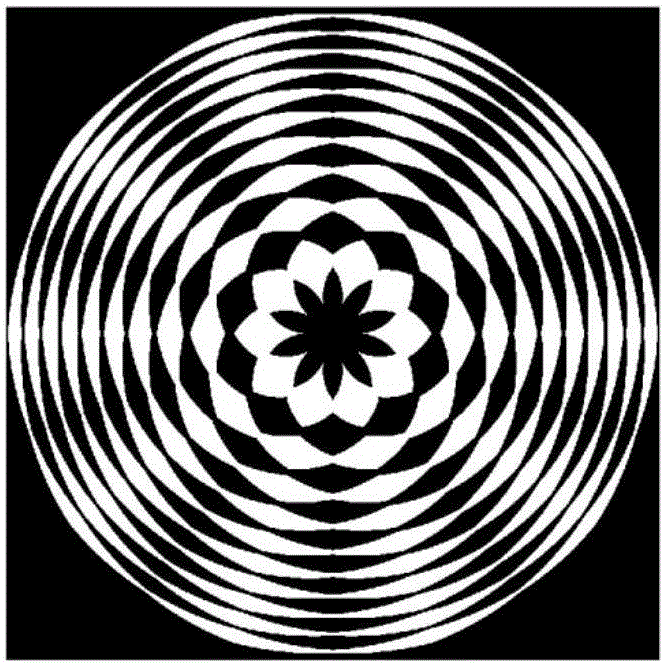

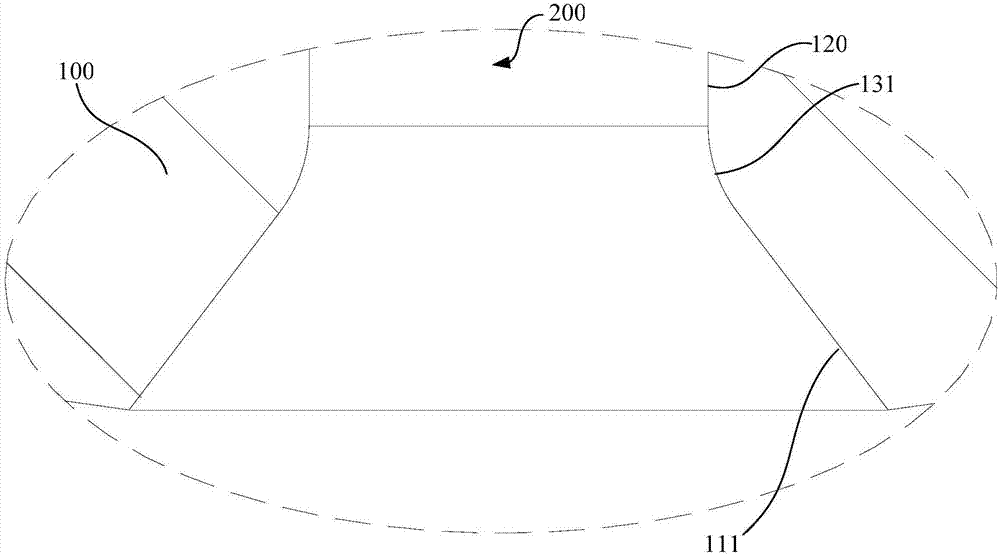

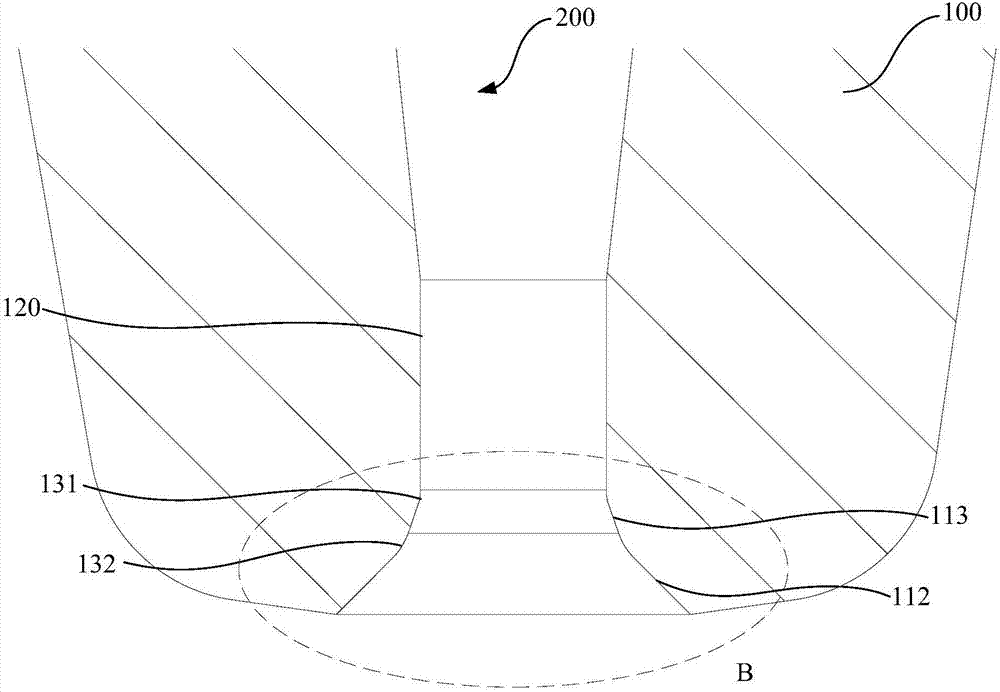

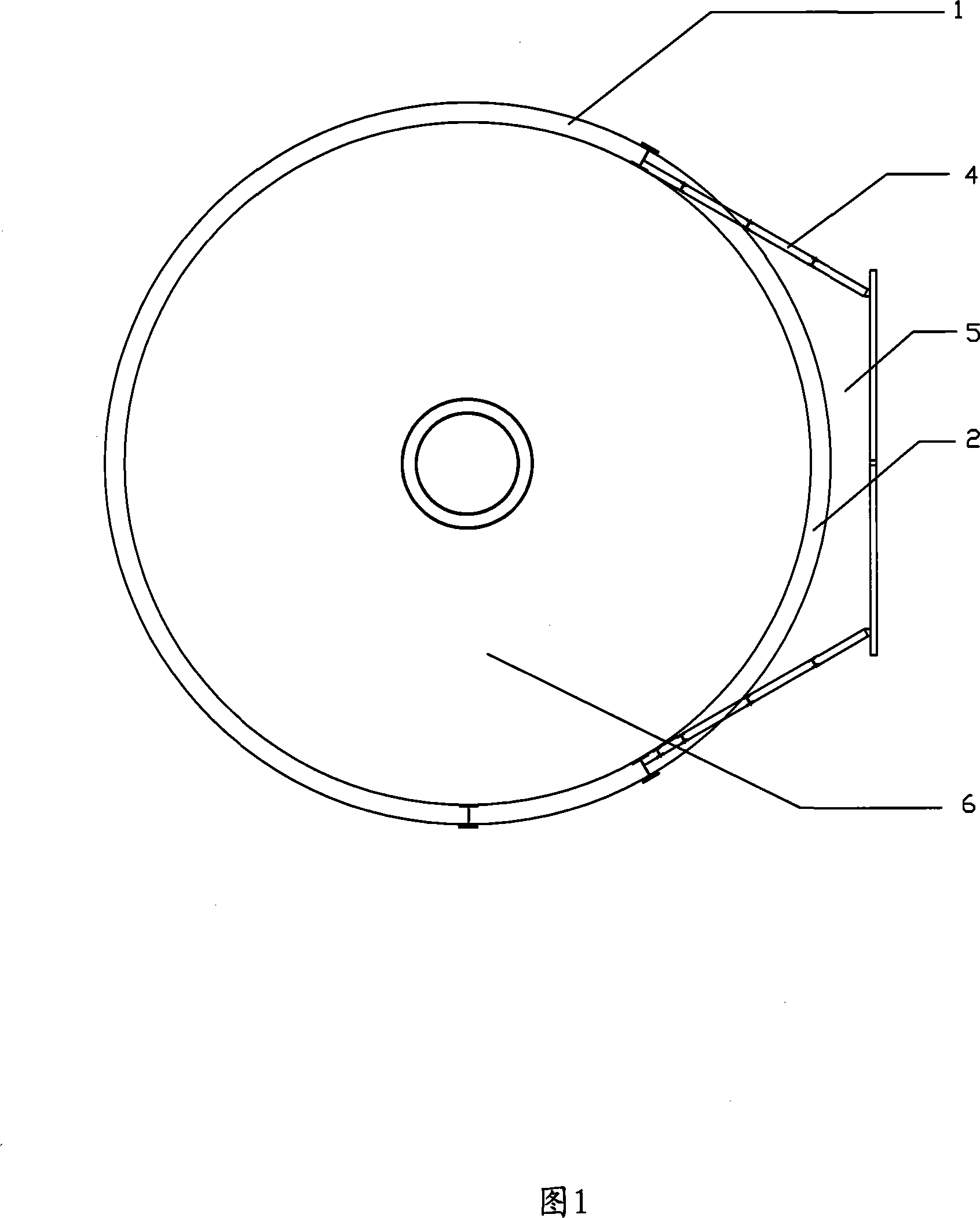

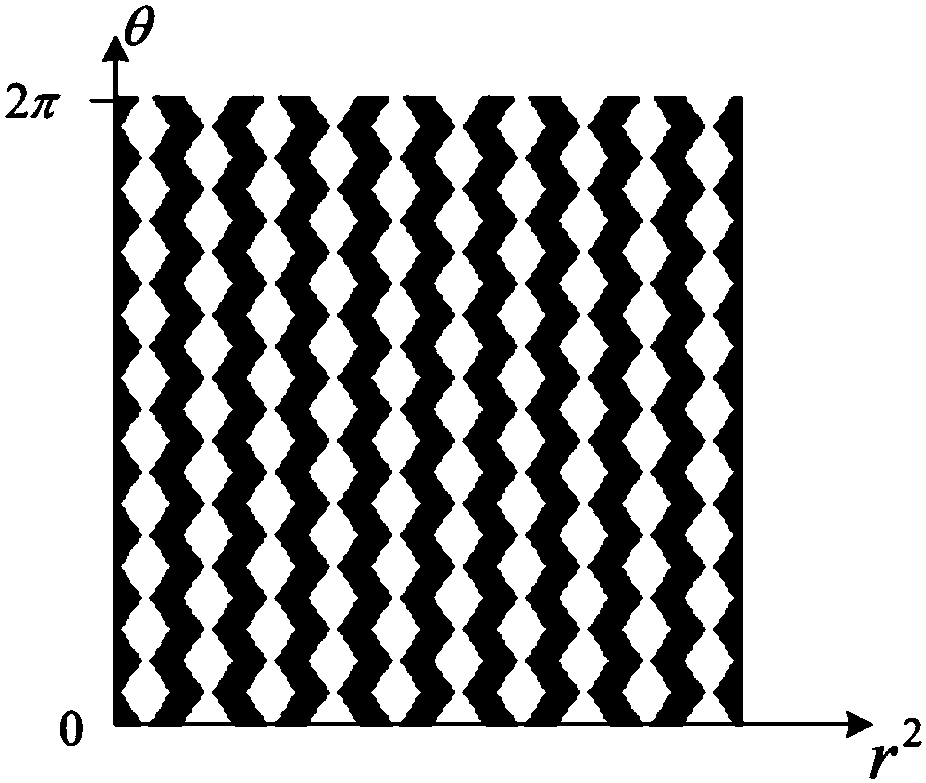

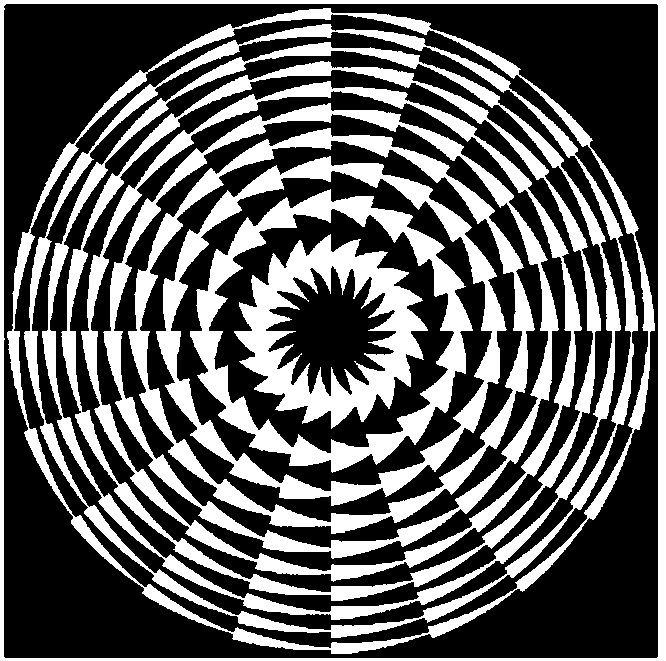

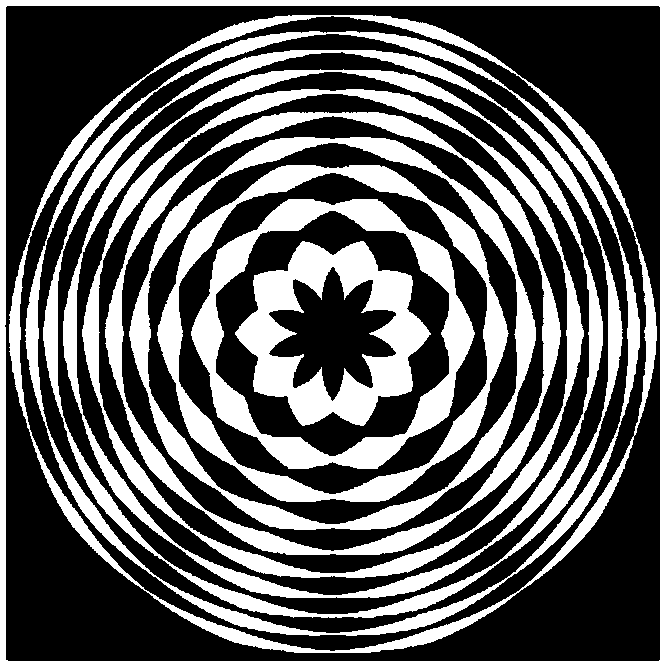

Trapezoidal wave zone plate with quasi-single-stage focusing characteristic

InactiveCN105866870ASelf-supportingDoes not affect diffraction resultsDiffraction gratingsIsosceles trapezoidSingle stage

The invention discloses a trapezoidal wave zone plate with a quasi-single-stage focusing characteristic. The trapezoidal wave zone plate comprises a light-proof substrate and a plurality of ring-shaped wave zones which are sequentially arranged from inside to outside by taking the substrate as a center, wherein each ring-shaped wave zone comprises at least two spiral trapezoidal hole light transmission units which are formed by twisting isosceles-trapezoid-shaped hole light transmission units, and are sequentially connected; the radial light transmittance of the wave zone plate meets a formula shown in the description. Compared with a common Fresnel wave zone plate, the trapezoidal wave zone plate can restrain the diffraction efficiency of a senior focus very well, also can reduce the peak strength of the senior focus. Moreover, when a ratio of the top edge of the original trapezoid to the bottom edge of the original trapezoid is equal to 1 to 5, the trapezoidal wave zone plate further has the effect of eliminating a 3n-level focus, and also restrains the efficiency of a 5-level focus to 0.16% of a 1-level focus (insulating efficiency being 6.93%). Compared with a Gabor wave zone plate, the 1-level focus efficiency is higher than the focusing efficiency of the Gabor wave zone plate, and the trapezoidal wave zone plate is easier to manufacture in comparison with a plurality of binaryzation Gabor wave zone plates.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

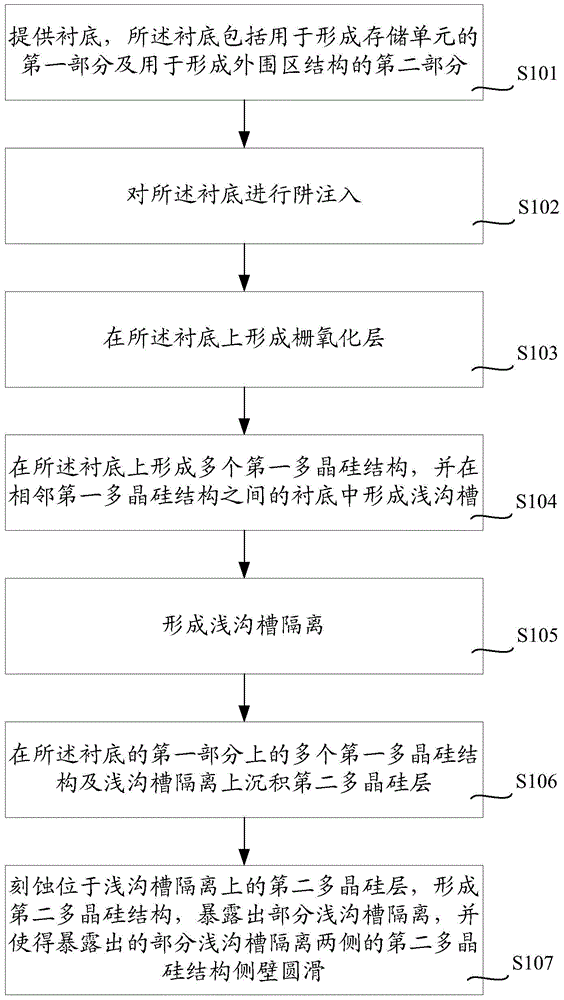

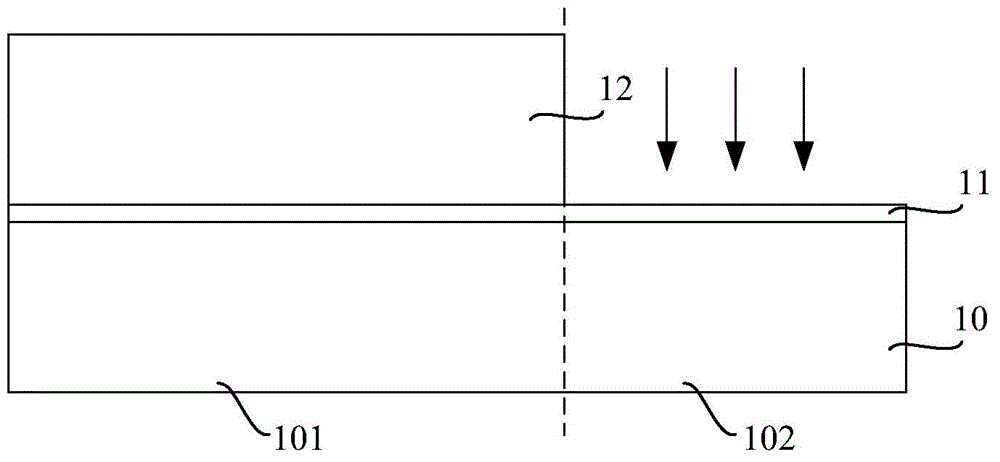

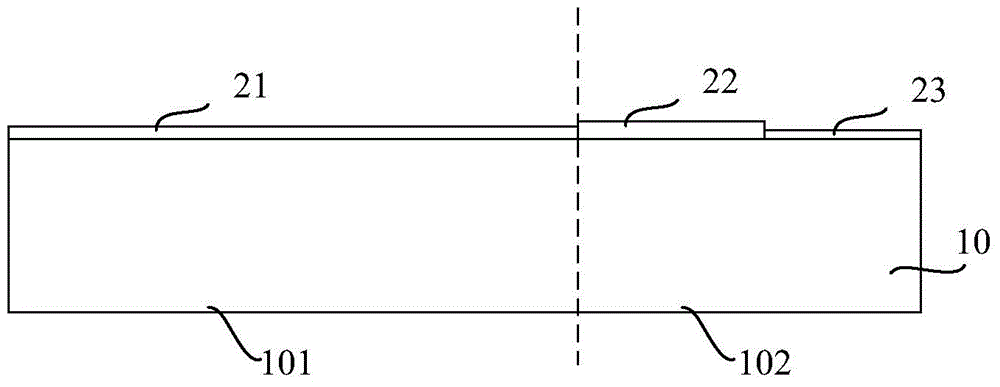

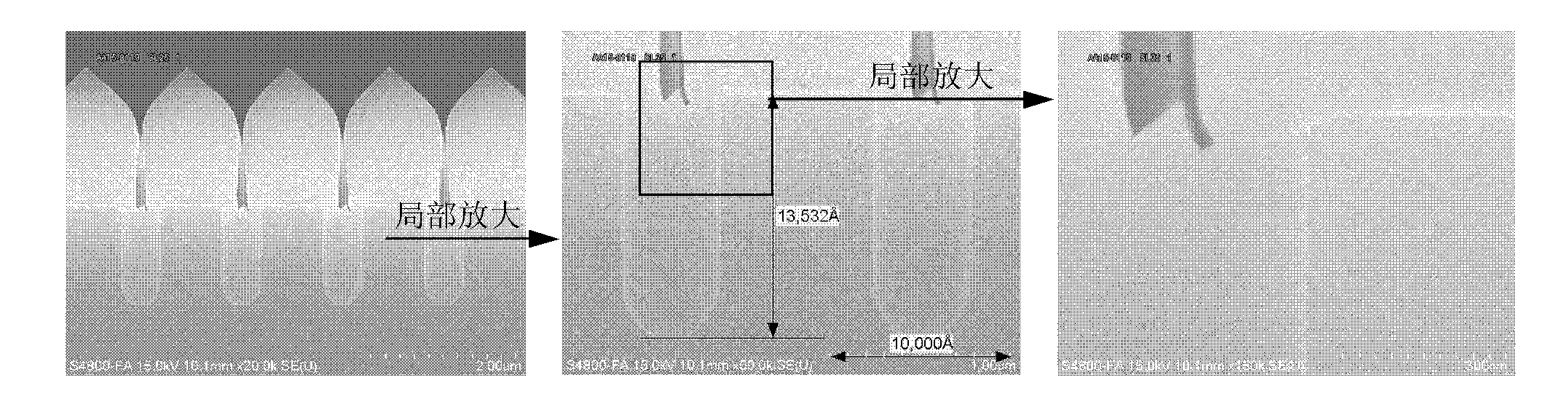

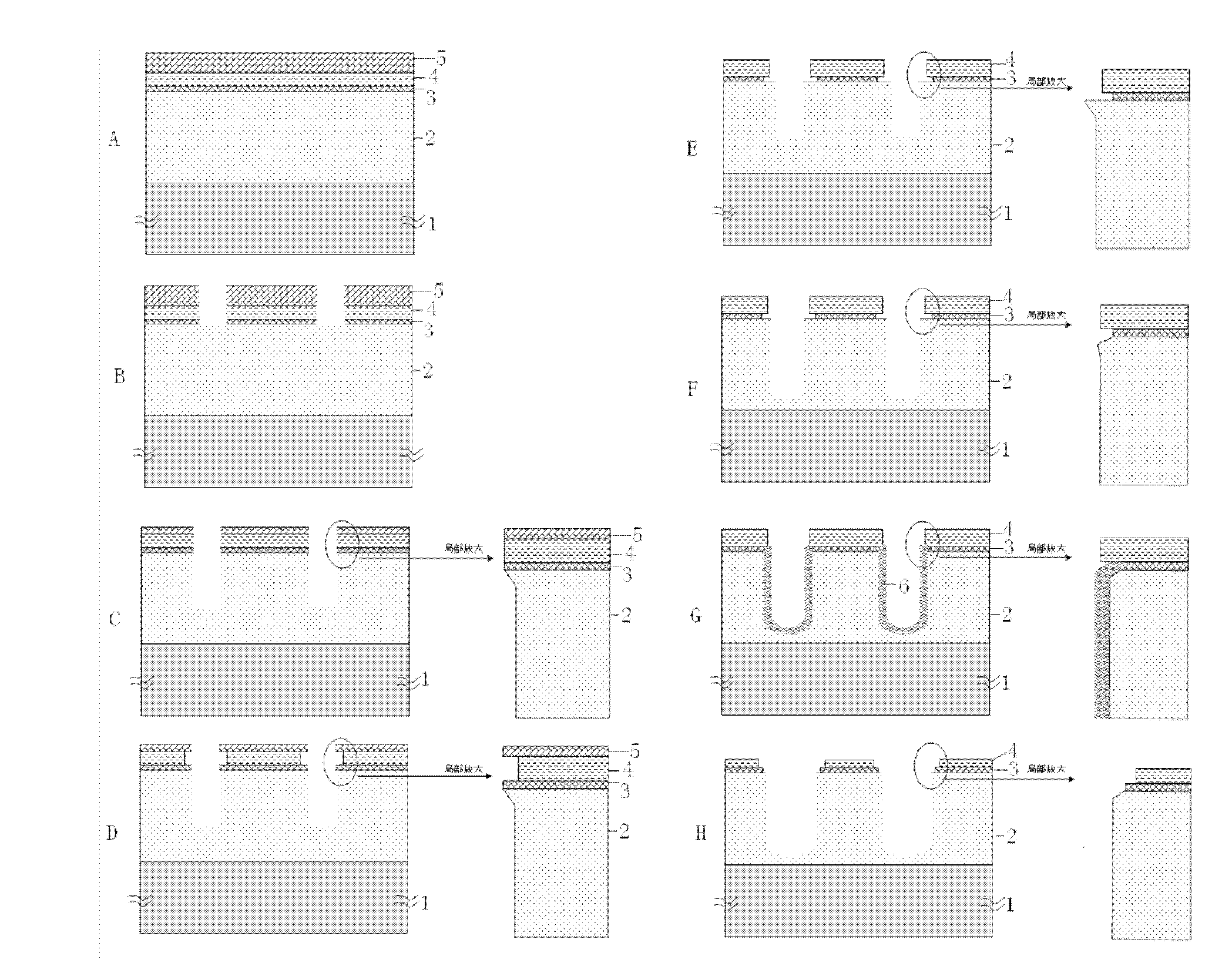

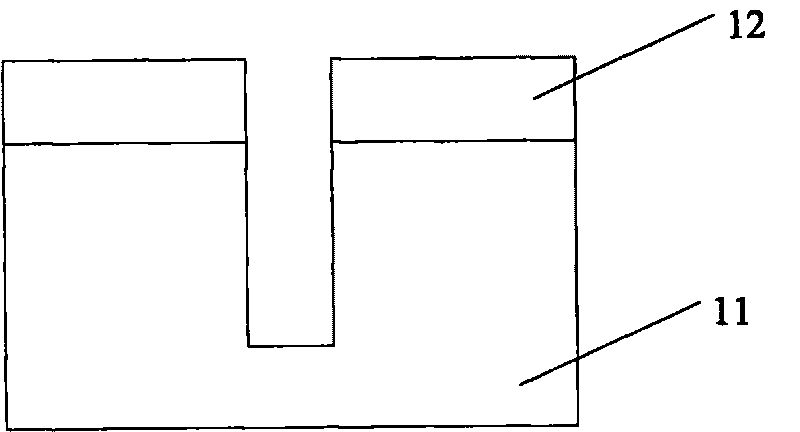

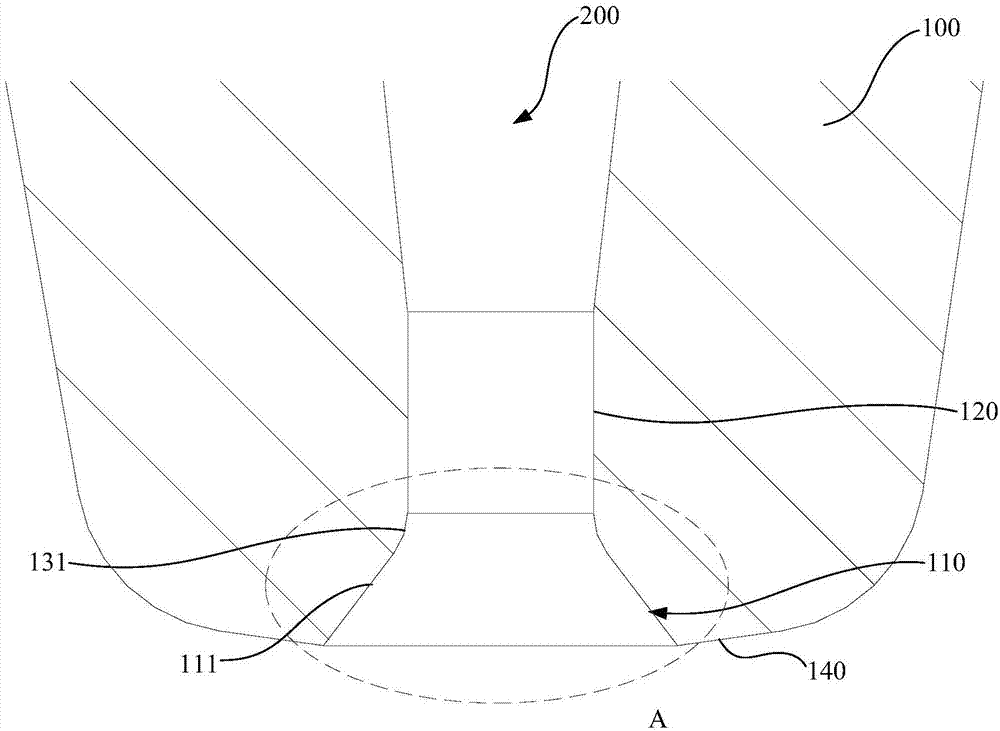

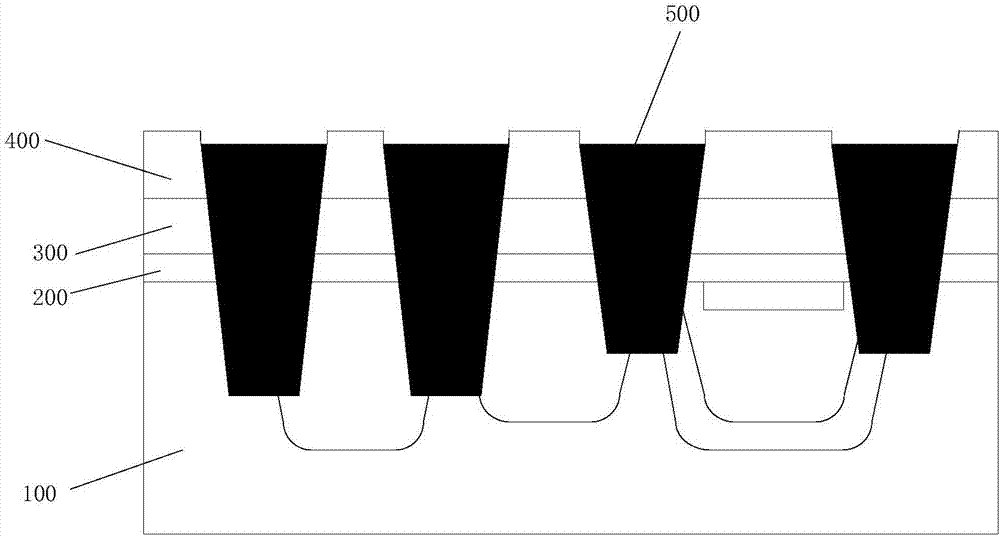

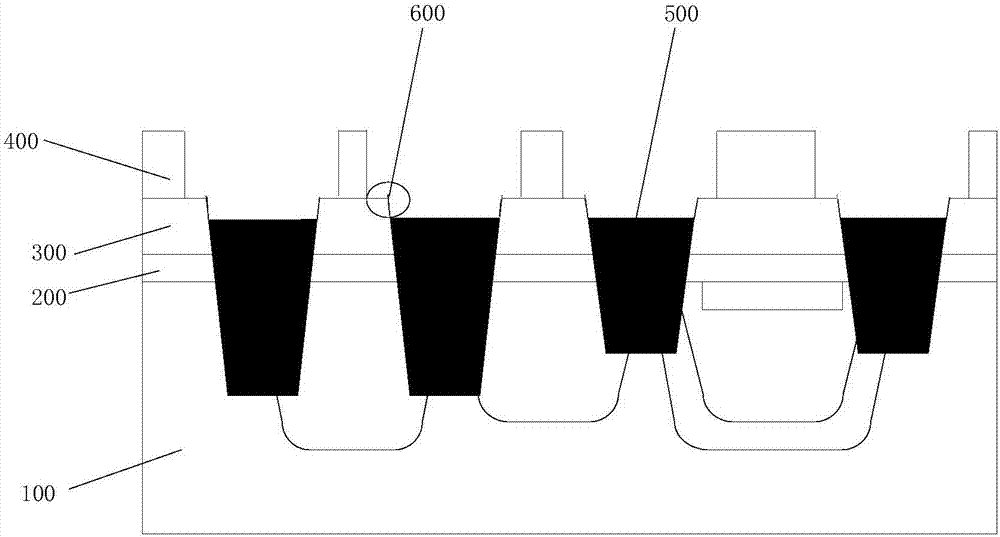

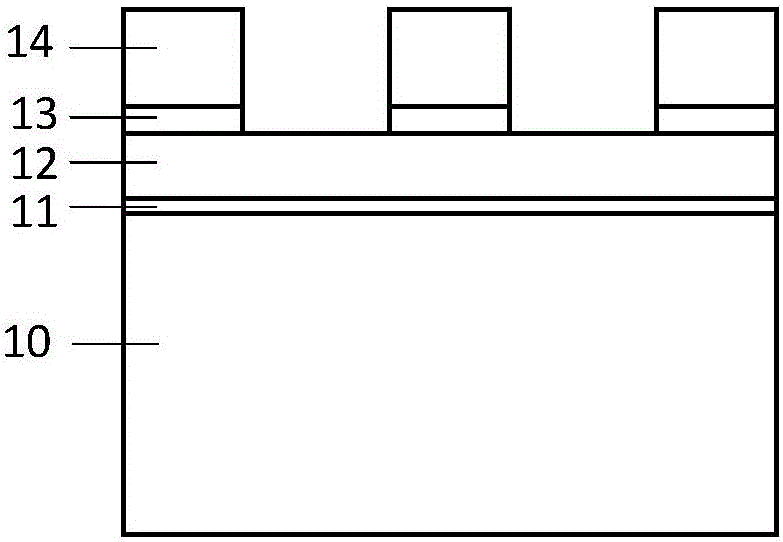

Floating gate structure and manufacturing method thereof

The invention discloses a floating gate structure and a manufacturing method thereof. The method comprises the steps of providing a substrate which comprises a first part and a second part, performing well injection on the substrate, continuously forming a gate oxide layer, then forming a plurality of first polycrystalline silicon structures, forming shallow grooves in the substrate between the adjacent first polycrystalline silicon structures, forming shallow groove isolation, depositing a second polycrystalline silicon layer on the first polycrystalline silicon structures and the shallow groove isolation on the first part, etching the second polycrystalline silicon layer, forming second polycrystalline silicon structures, exposing partial shallow groove isolation, and allowing side walls of the second polycrystalline silicon structures on the two sides of the exposed partial shallow groove isolation to be smooth. The method saves a photomask, simplifies a technology, and achieves perfect alignment of floating gate polycrystalline silicon and an active region. An application of a floating gate polycrystalline silicon side wall technique meets a control gate and floating gate coupling requirement, eliminates a sharp corner, and facilitates storing charge in floating gate polycrystalline silicon.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

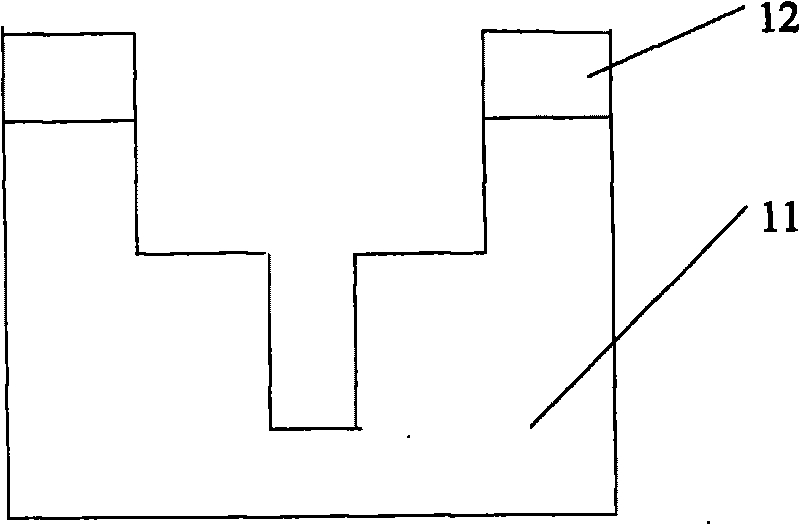

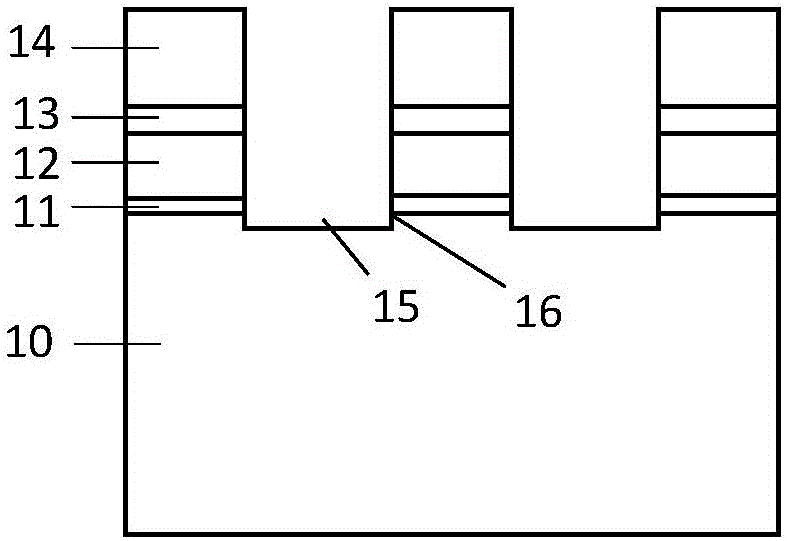

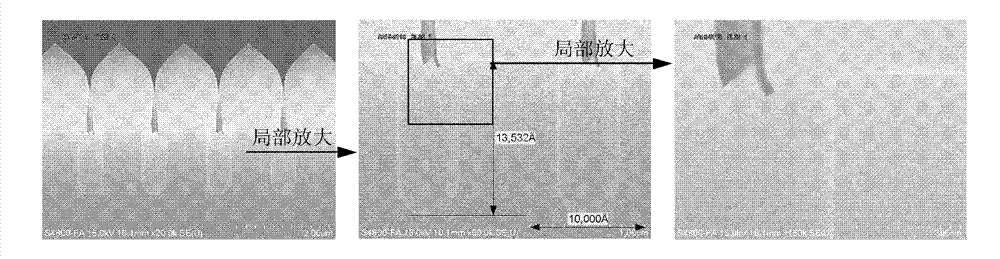

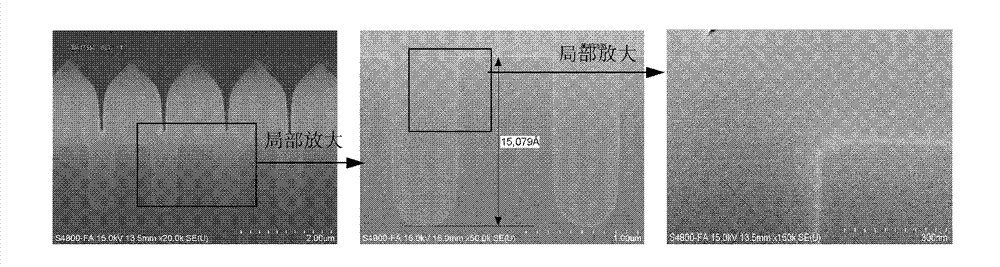

Method for eliminating sharp corner at top end of groove

ActiveCN103137483ASpeed up etchingEliminate sharp cornersSemiconductor/solid-state device manufacturingHelix-destabilizing proteinsCompound (substance)

The invention discloses a method for eliminating a shaft corner at the top end of a groove. The method comprises the steps of 1, enabling oxide-nitride-oxide (ONO) to grow, 2, enabling the ONO to be etched, 3, enabling the groove to be etched, wherein the ONO serves as hard mask for dry etching, 4, enabling middle silicon nitride of the hard mask to be etched by a transverse wet method, wherein the sharp corner at the top end of the groove is required to be exposed completely, 5, enabling top layer oxidation film remained on the hard mask to be etched in a complete mode, and meanwhile enabling bottom oxidation film of the hard mask to be etched in transverse mode, 6, conducting homodromous etching at the bottom of the groove, and meanwhile conducting transverse etching and vertical etching for the sharp corner at the top end of the groove so as to reduce the sharp corner at the top end, 7, enabling a sacrificed oxide layer to grow inside the groove, enabling the sharp corner at the top end of the groove to be completely oxidized and to be disappeared, 8, enabling the sacrificed oxide layer to be etched in the wet method, enabling the silicon nitride to be etched in the wet manner, and keeping part of the silicon nitride serving as a barrier layer for helix destabilizing protein (HDP) chemical mechanical lapping. According to the method for eliminating the shaft corner at the top end of the groove, the sharp corner at the top end of the groove can be eliminated, and the fact that trailing HDP can fill the groove without holes is guaranteed.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

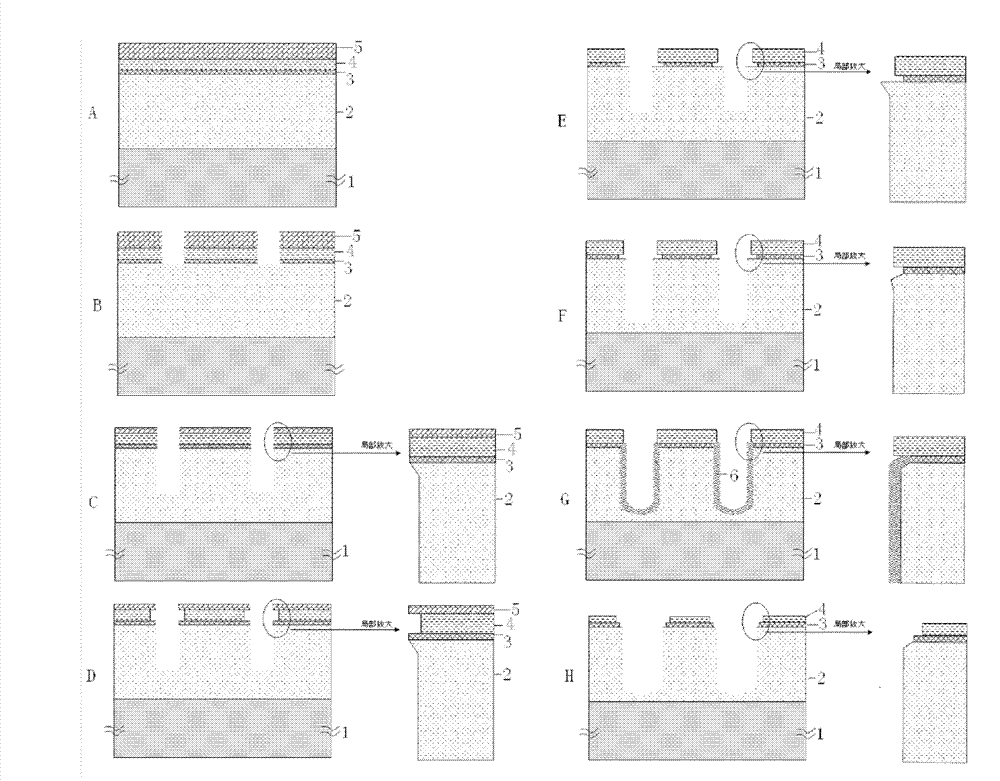

Method for preventing cavities from generating in deep groove insulation technology

InactiveCN101710575AEliminate sharp cornersAvoid voidsSemiconductor/solid-state device manufacturingPhysicsSilicon oxide

The invention provides a method for preventing cavities from generating in deep groove insulation technology, which comprises the following steps: forming an source region protective layer on a semiconductor substrate; etching the source region protective layer and the semiconductor substrate to form a deep groove; etching the source region protective layer and the semiconductor substrate to form a shallow groove communicated with the deep groove; adopting a high temperature oxidation technology on the edge of the deep groove and the edge of the shallow groove; carrying out etching by the wet method to remove the silicon oxide formed by the high temperature oxidation technology, and precipitating an insulating medium in the deep groove and the shallow groove; carrying out the chemical machinery grinding to flatten the surface of the shallow groove. The method of the invention enables the edges and corners of the grooves to be smooth, thereby avoiding large quantities of cavities in the groove and ensuring the insulating property of the groove.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

Method for producing stainless steel slab by radian chamfer crystallizer continuous casting machine

The invention discloses a method for producing a stainless steel slab by a radian chamfer crystallizer continuous casting machine. The method comprises the steps of molten iron dephosphorization, TSRfurnace smelting, LF refining and continuous casting; and according to the continuous casting process, the radius R of a chamfer arc of a crystallizer is 80-82 degrees, the diameter width of the chamfer arc is 39-40 mm, the flow rate of cooling water in a copper plate water tank of the chamfer crystallizer is 7.9-8.2 m / min, the water quantity of the narrow surface of the chamfer crystallizer is 450-550 L / min, and the water quantity of the wide surface is 3800-4200 L / min. Compared with the prior art, the method adopts molten iron pre-dephosphorization and TSR furnace desulfurization process, the soft blowing and calming time is prolonged by an LF furnace, low oxygen, low phosphorus and low sulfur are realized, and inclusions are controlled; cooling parameters of the crystallizer and a fan-shaped section are designed to adopt a conventional pressing mode and electromagnetic stirring so as to slow down the corner cooling strength of a casting blank and eliminate corner cracks and sharp corners; the edge loss phenomenon of a hemmed part of hot rolled steel is avoided; and therefore, the depth and the width of a slit line of a steel coil product are reduced, the product quality is improved, and the economic benefits are greatly improved.

Owner:SHANDONG TAISHAN STEEL GROUP

Chopper structure

ActiveCN107275242AEliminate sharp cornersAvoid scratchesSolid-state devicesSemiconductor/solid-state device manufacturingSolderingEngineering

The invention relates to a chopper structure which comprises a chopper body. The copper body is internally provided with a conical wall of which the central axis is superposed with that of the chopper body, wherein the conical wall is next to the end of the copper body, an inner chamber wall which is coaxially arranged with the conical wall, and a first arc-shaped transition wall which is connected with the conical wall and the inner chamber wall. The conical wall, the inner chamber wall and the first arc-shaped transition wall form a wire passing through hole for passing of a solder wire. In a movement process of the solder wire relative to the wire passing through hole, because the first arc-shaped transition wall is connected between the conical wall and the inner chamber wall, a closed angle at a connection part between the conical wall and the inner chamber wall is eliminated, and smooth transition of the connection between the conical wall and the inner chamber wall is realized, thereby effectively preventing scratch of the closed angle to the surface of the solder wire, ensuring high mechanical strength of the solder wire, realizing no easy pulling breakage or fatigue breakage of the solder wire by an external impact force or an alternate stress, and ensuring high soldering quality of the solder wire.

Owner:CHAOZHOU THREE CIRCLE GRP

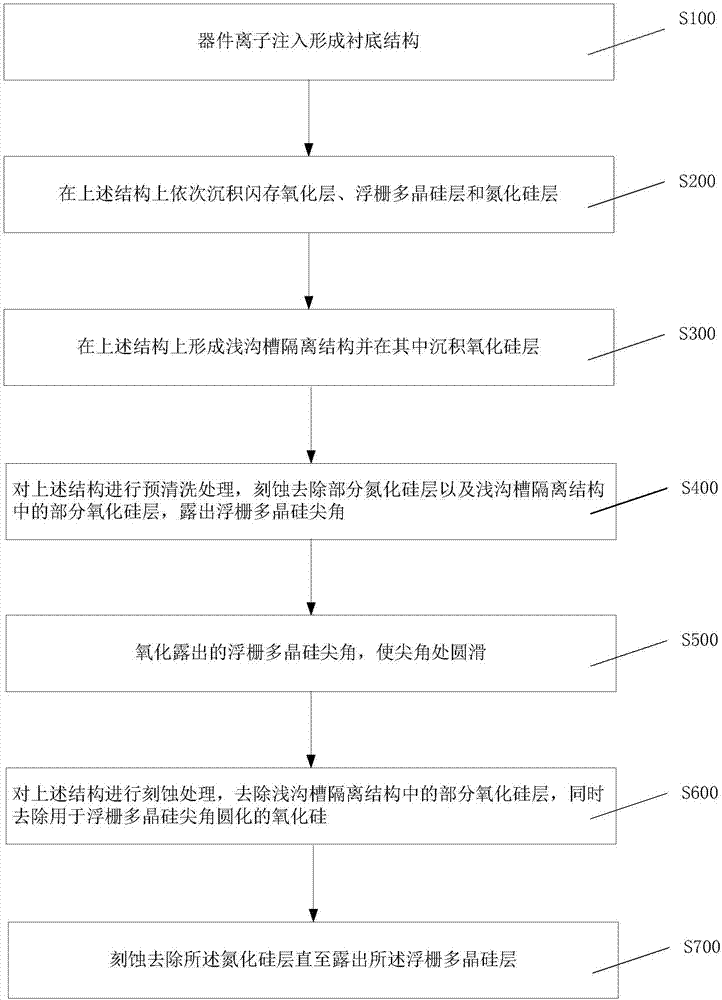

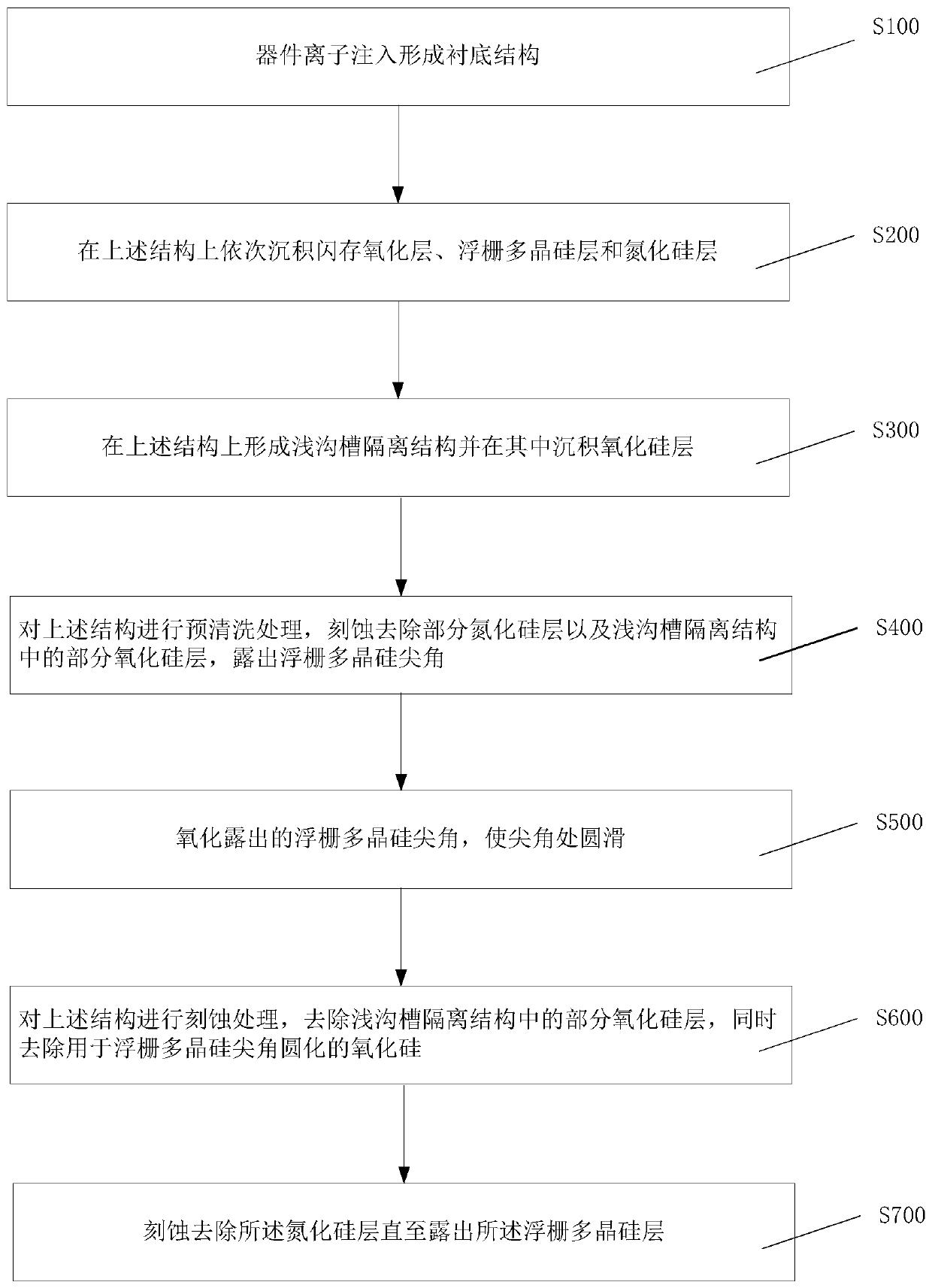

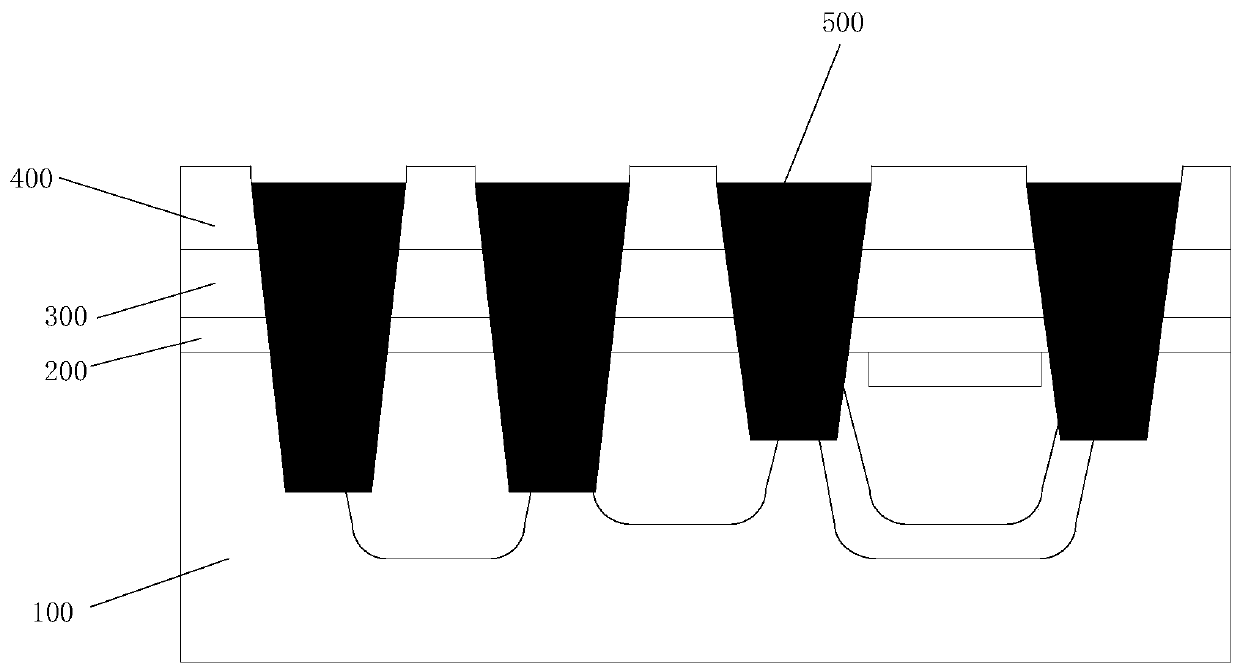

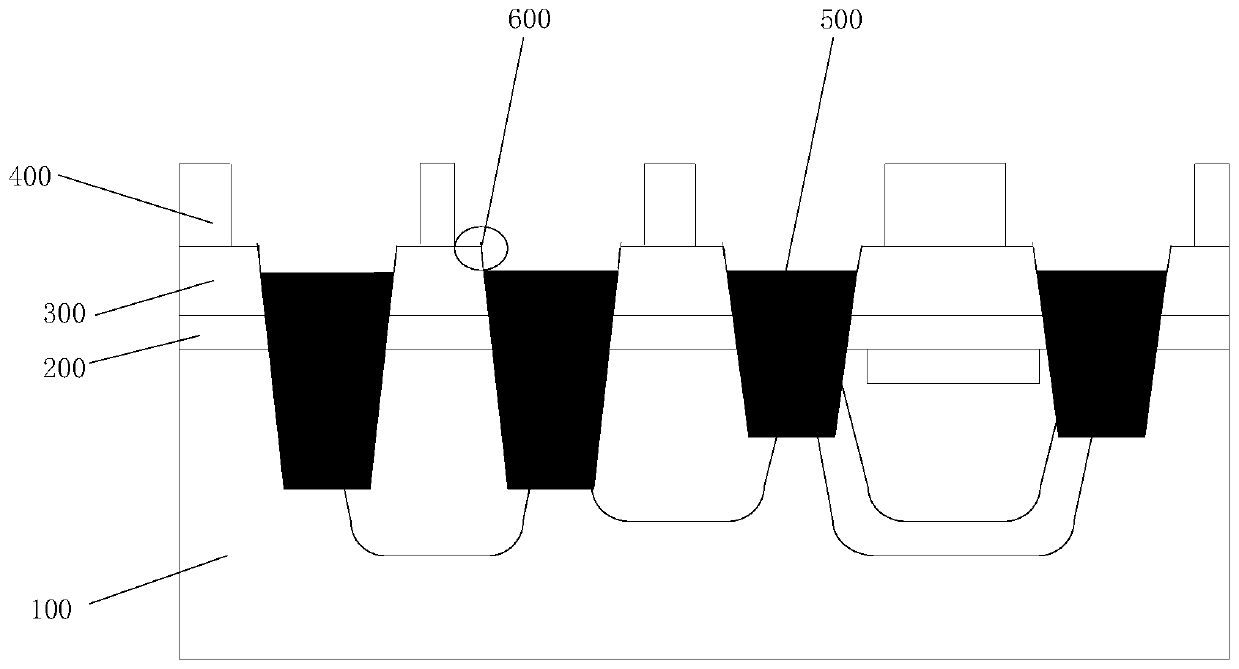

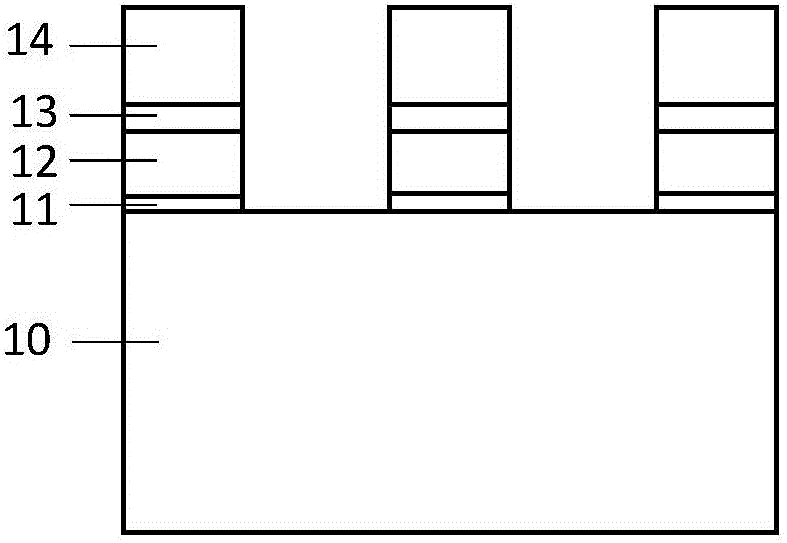

Process integration method for improving flash memory unit

ActiveCN107887390AImproved Process Integration MethodsEliminate sharp cornersSolid-state devicesSemiconductor devicesProcess integrationSilicon oxide

The invention provides a process integration method for improving a flash memory unit. The method comprises steps that a substrate structure is formed through device ion implantation; a flash memory oxide layer, a floating gate polysilicon layer and a silicon nitride layer are sequentially deposited; a shallow trench isolation structure is formed, and a silicon oxide layer is deposited on the shallow trench isolation structure; pre-cleaning processing is carried out, the silicon nitride layer and the silicon oxide layer of the shallow trench isolation structure are partially removed through etching to expose a floating gate polysilicon tip; the exposed floating gate polysilicon tip is oxidized to round the tip; etching processing is carried out, the silicon oxide layer of the shallow trench isolation structure is partially removed, and the silicon oxide for rounding the floating gate polysilicon tip is further removed; the silicon nitride layer is removed through etching till the floating gate polysilicon layer is exposed. The method is advantaged in that arcing of the floating gate tip is realized in advance through the added silicon oxide, arcing of the floating gate tip and thenon-damaged flash memory unit at the top portion of the floating gate are realized, and another optimization method is provided for continuously reducing the flash memory unit.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

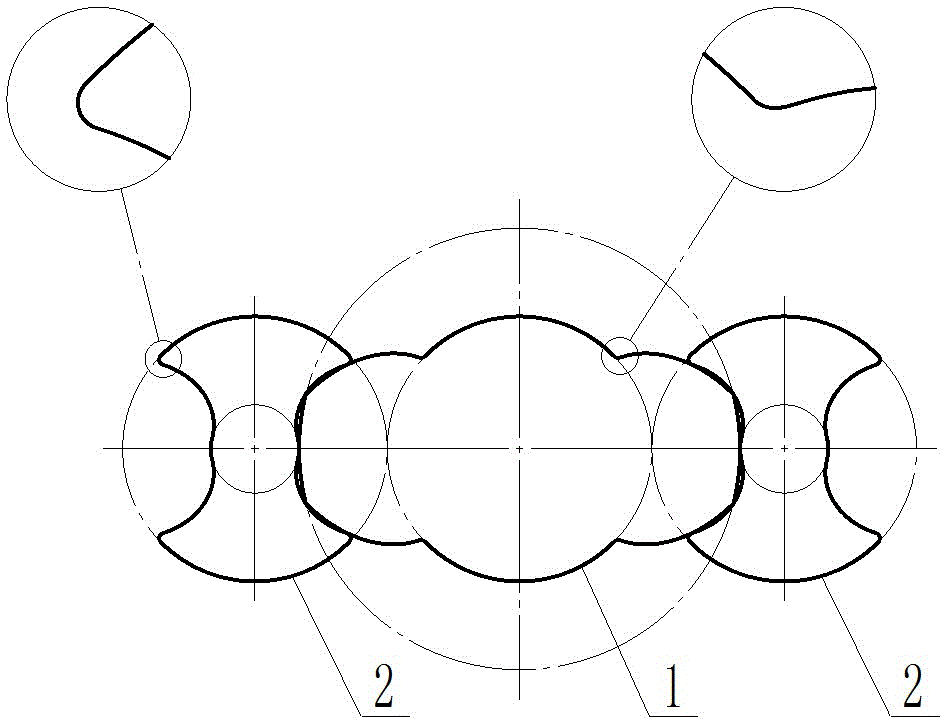

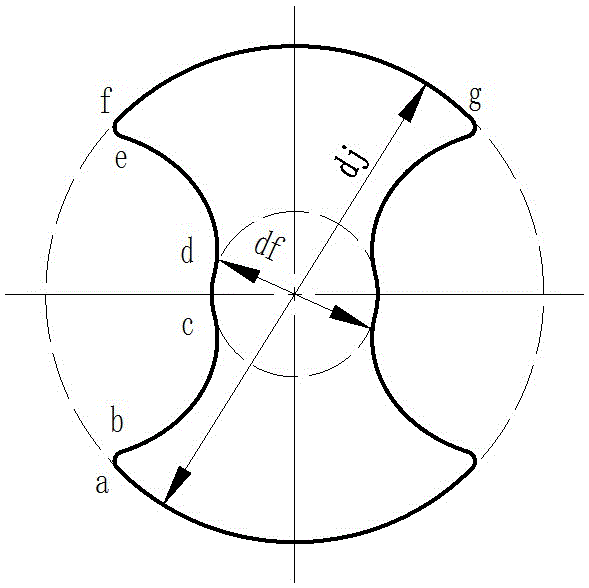

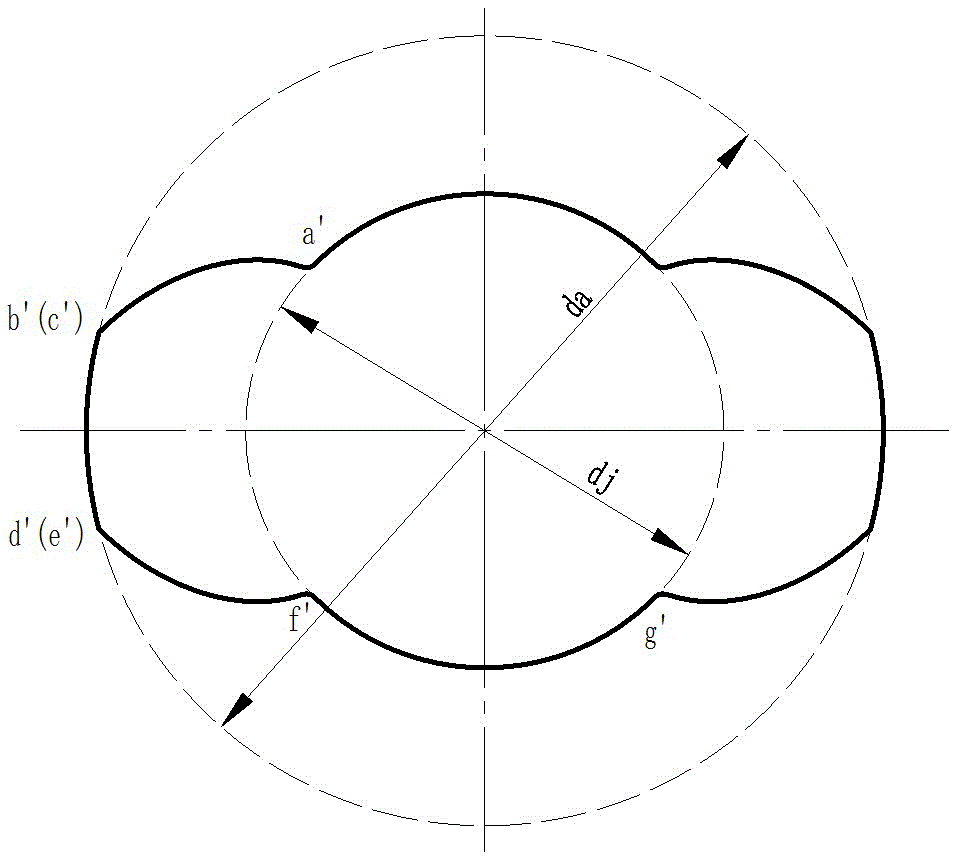

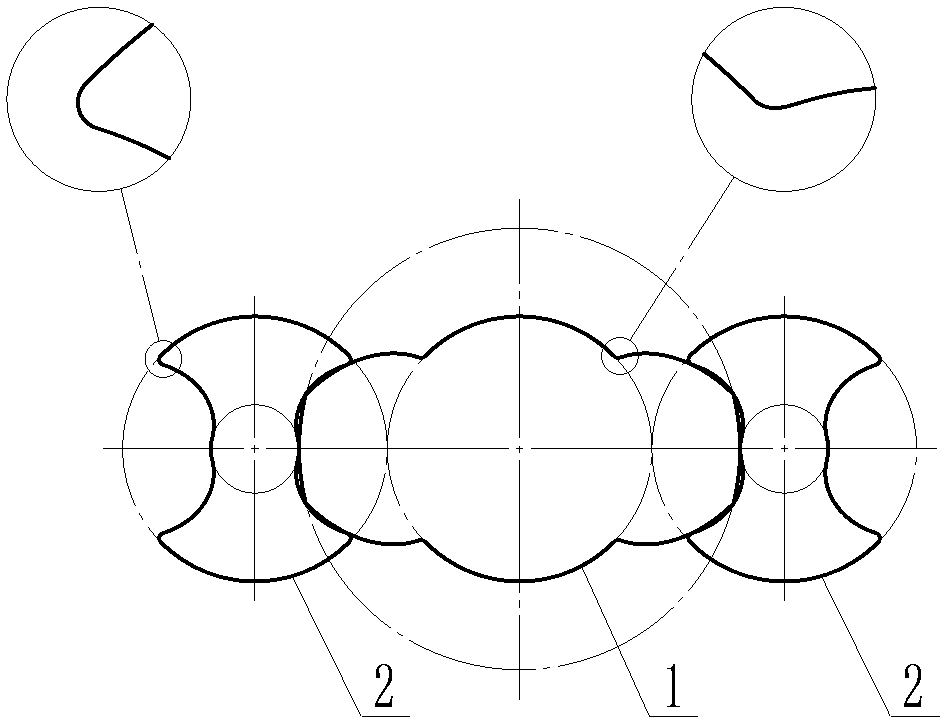

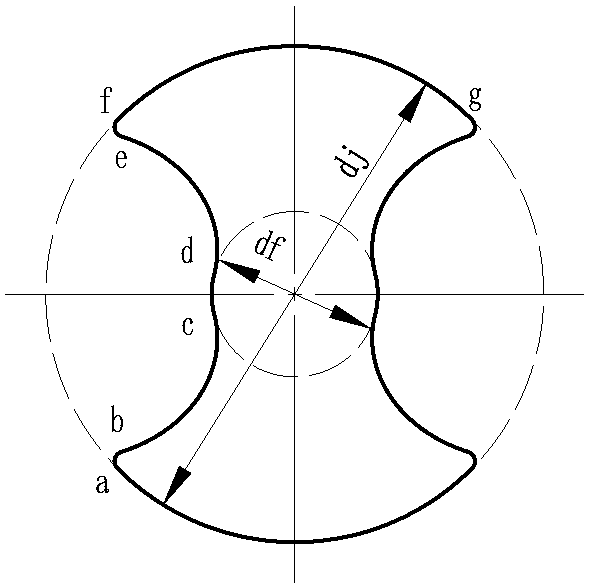

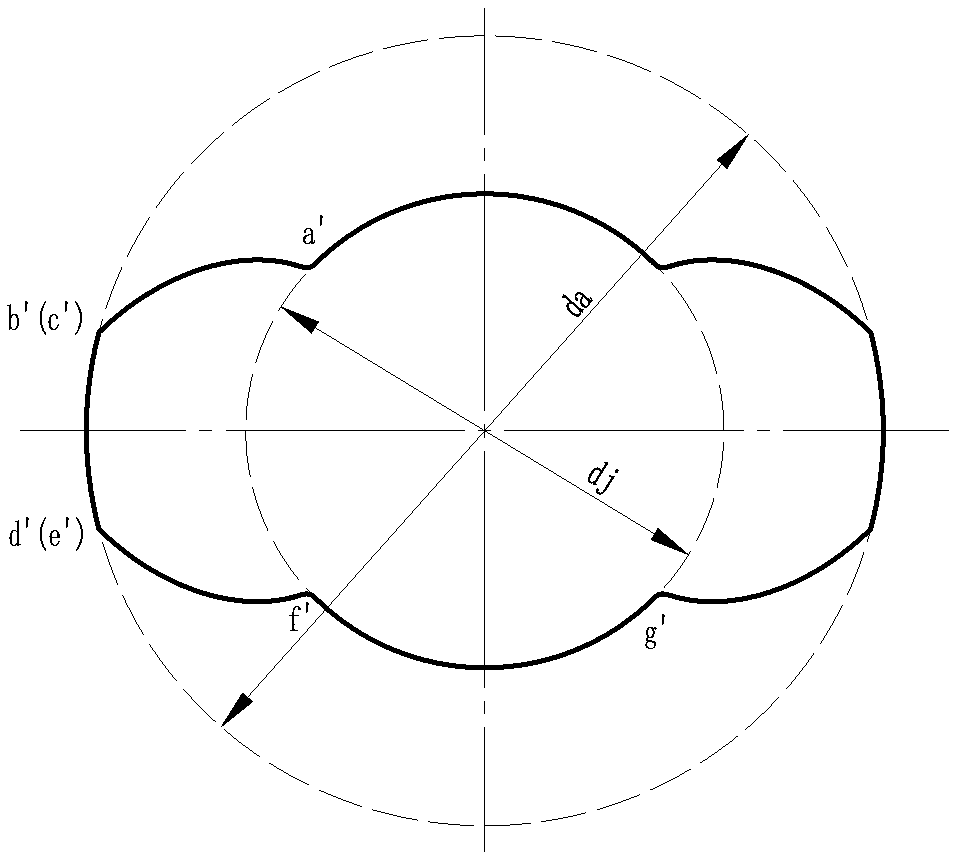

Triple screw for correcting tooth profiles through arcs

ActiveCN106122005AExtend working lifeStable Volumetric EfficiencyRotary piston pumpsRotary piston liquid enginesWorking lifeMilling cutter

The invention discloses a triple screw for correcting tooth profiles through arcs. The triple screw comprises two double-end driven screw bodies and a double-end driving screw body. The driving screw body is located in the middle, and the driven screw bodies are symmetrically arranged along the circumference of the driving screw body. Each tooth profile of each driven screw body is composed of the transition arc, a long-amplitude epicycloid, a tooth root circle and a tooth crest circle. Each tooth profile of the driving screw body is composed of an arc envelope line, a tooth crest circle and a tooth root circle. The design range of the radius of the transition arc in each tooth profile of each driven screw body is ro / dj, and the value ranges from 0.015 to 0.025. According to the triple screw for correcting the tooth profiles through the arcs, smoothness is achieved in the engagement process, wear resistance of the driven screw bodies is remarkably improved, the work life of a screw pair is prolonged by about 30% to 40%, and the stable volume efficiency is kept. In addition, when a disc milling cutter or a grinding wheel machines the driving screw body, the service life of the cutter is prolonged by about 50%, and the machining difficulty is reduced.

Owner:黄山工业泵制造有限公司

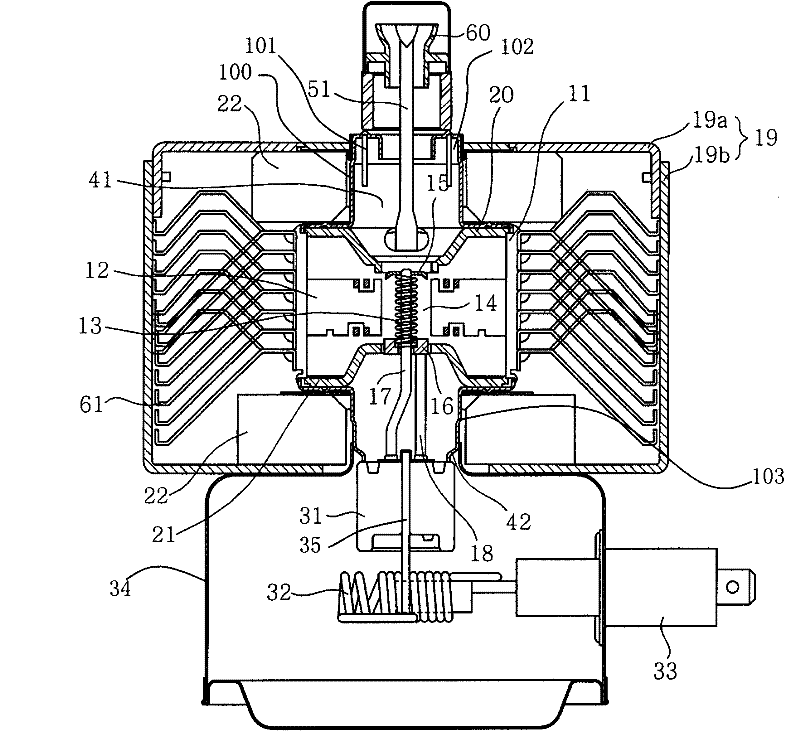

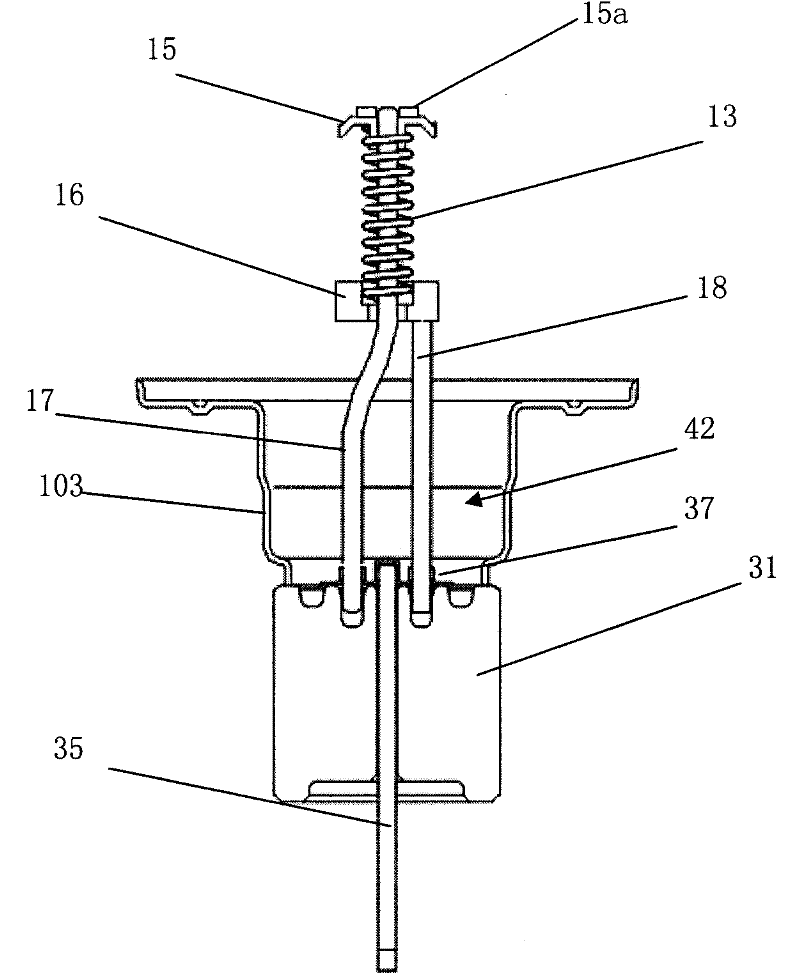

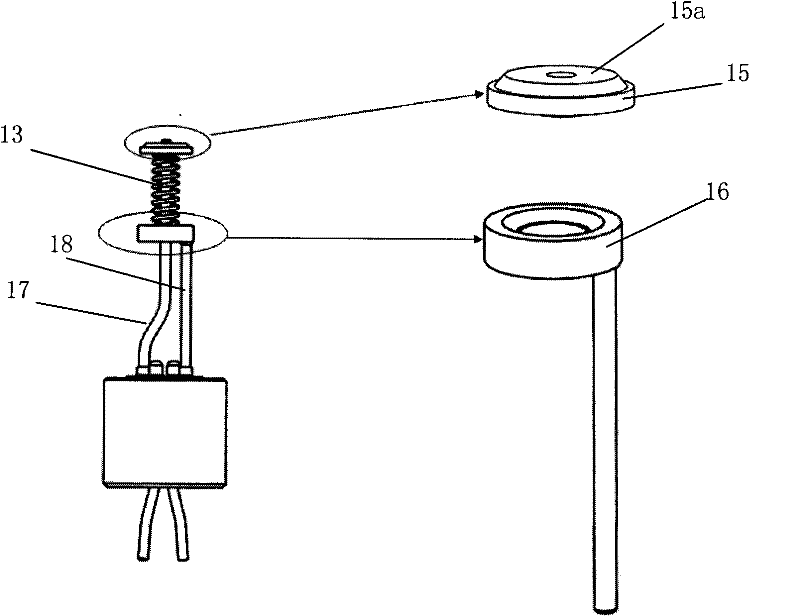

Negative part structure of magnetron

The invention relates to a negative part structure of a magnetron. A shielding cap with a smooth structure and an upper convex cambered surface is formed at the upper end of an upper sealing element; the surface area of the upper surface of the shielding cap is correspondingly increased, so that the radiance of the upper surface of the shielding cap is improved to make energy collected on a negative part of the magnetron timely and outwards diffused, cool the shielding cap and the whole negative part of the magnetron, enable the negative part of the magnetron to operate at normal temperature, avoid the damage to the magnetron caused by over-high temperature of the negative part, and prolong the normal service life of the magnetron. Arc bevel angles are positioned at junctions of all planes and circumference surfaces of the upper sealing element and a lower sealing element, the original closed angles on all parts of the negative part are eliminated, the magnetron is prevented from high-voltage breakdown caused by the closed angles, and a product fault caused by fire striking of the magnetron negative is avoided.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Wet fuel gas desulfurizing absorption tower

ActiveCN101185842AEliminate sharp cornersGood for gas flowDispersed particle separationProcess engineeringAcute angle

The invention provides a wet flue gas desulfurization absorption tower, including a tower body, a tower top welded with a peak of the tower body, a purified flue gas outlet lateral plate welded with a lateral part of the tower body, an outlet roof and an outlet soleplate welded with a lateral plate, a purified flue gas outlet consists of the outlet lateral plate, the outlet roof and the outlet soleplate, the outlet roof is welded with the tower top; the outlet soleplate is welded with the tower body by a cambered connecting piece; a cross section of the cambered adapting piece is a part of a circle. As the holistic cambered connecting piece is adopted to be connected with the flue gas outlet soleplate and the absorption tower wall, the taper angle and the acute angle at a joint are eliminated, reduces overflowing phenomenon of high speed flue gas is reduced, and the service life of a lining is prolonged; workload of manufacturing and welding with subsections is lowered by a holistic cambered pipe, thus construction is easy.

Owner:CHINA SHENHUA ENERGY CO LTD +1

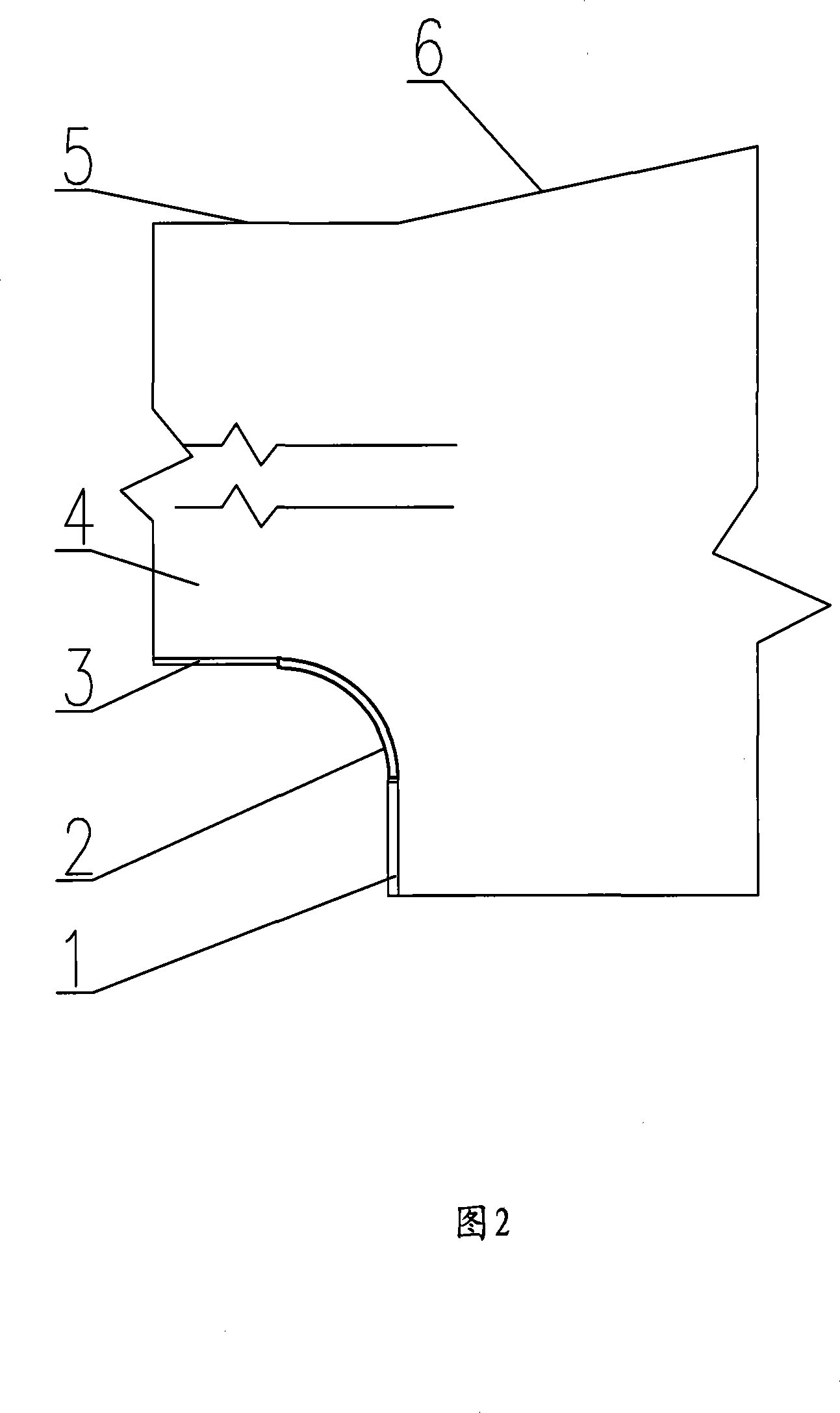

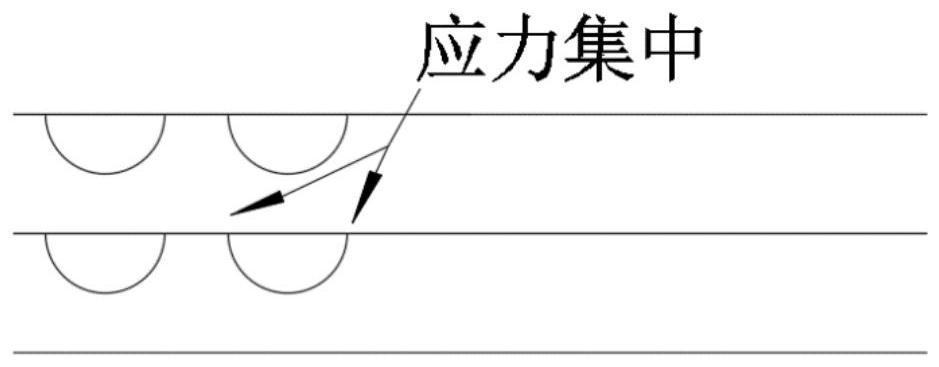

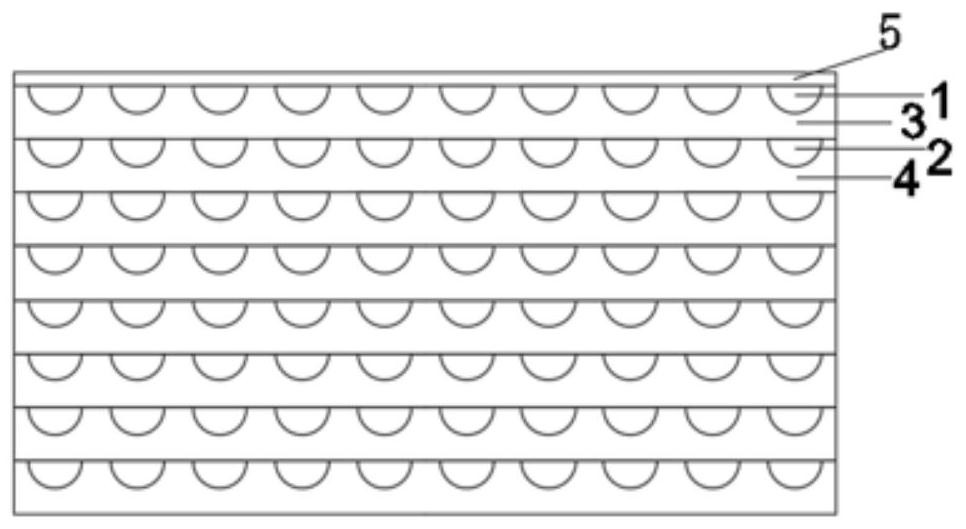

Printed circuit board heat exchanger core for reducing stress

PendingCN112272444AEliminate sharp cornersReduces mechanical and thermal stressCircuit thermal arrangementsPhysicsFluidic channel

The invention discloses a printed circuit board heat exchanger core for reducing stress. The printed circuit board heat exchanger core comprises a plurality of hot plates with hot fluid channels and cold plates with cold fluid channels, wherein the upper surfaces and the lower surfaces of the hot plate sheets and the cold plate sheets are respectively provided with a surface A with a semi-arc anda plane B with a semi-arc, and the surface A with the semi-arc and the surface A with the semi-arc are symmetrically connected to form a circular section channel; and the planes B are connected to form a wall surface between the cold fluid channel and the hot fluid channel. The stress borne by the core body can be greatly reduced, the size of the core body can also be reduced, the structure of theheat exchanger is more compact, and higher pressure and higher temperature can be borne.

Owner:XIAN THERMAL POWER RES INST CO LTD

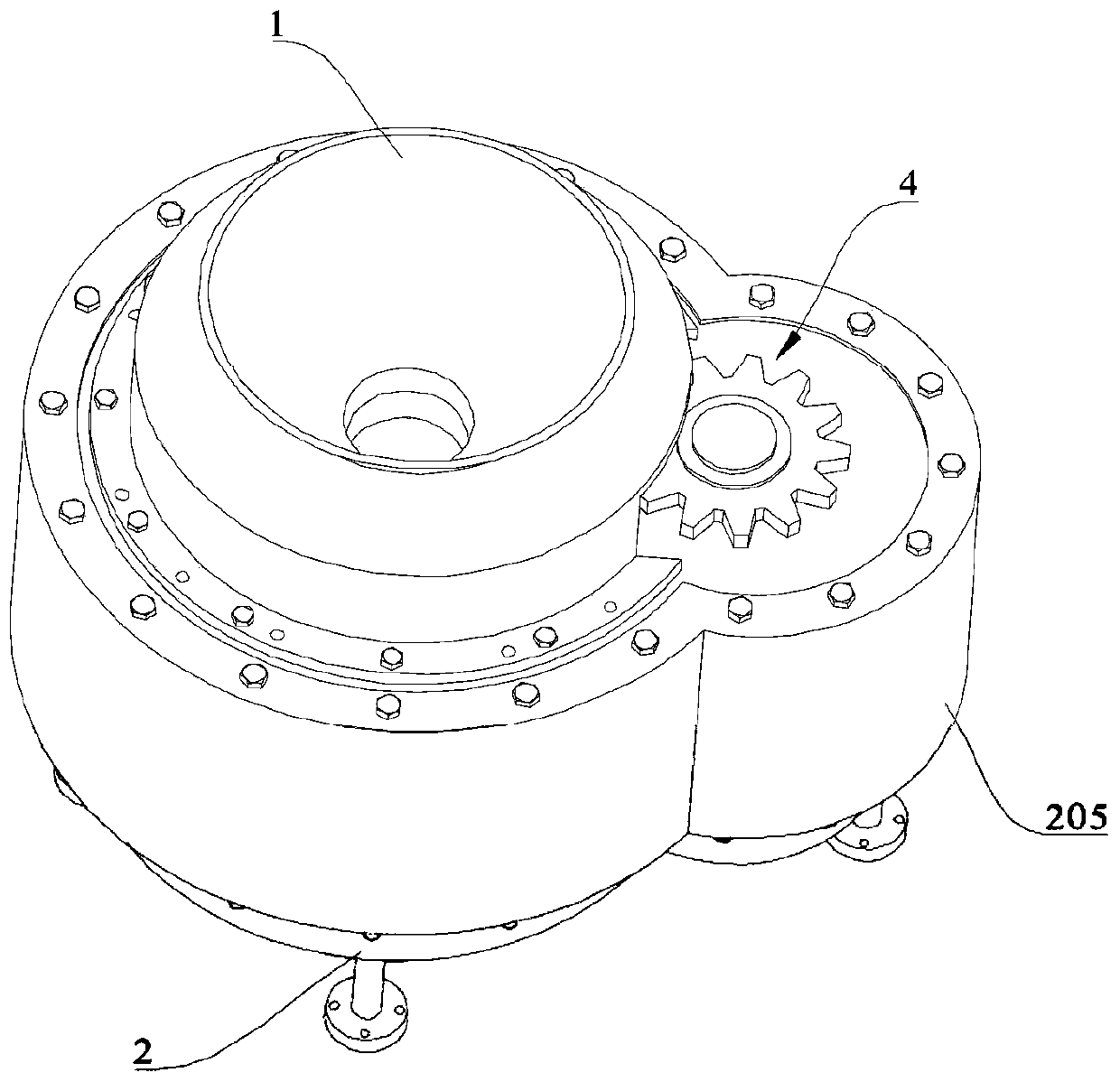

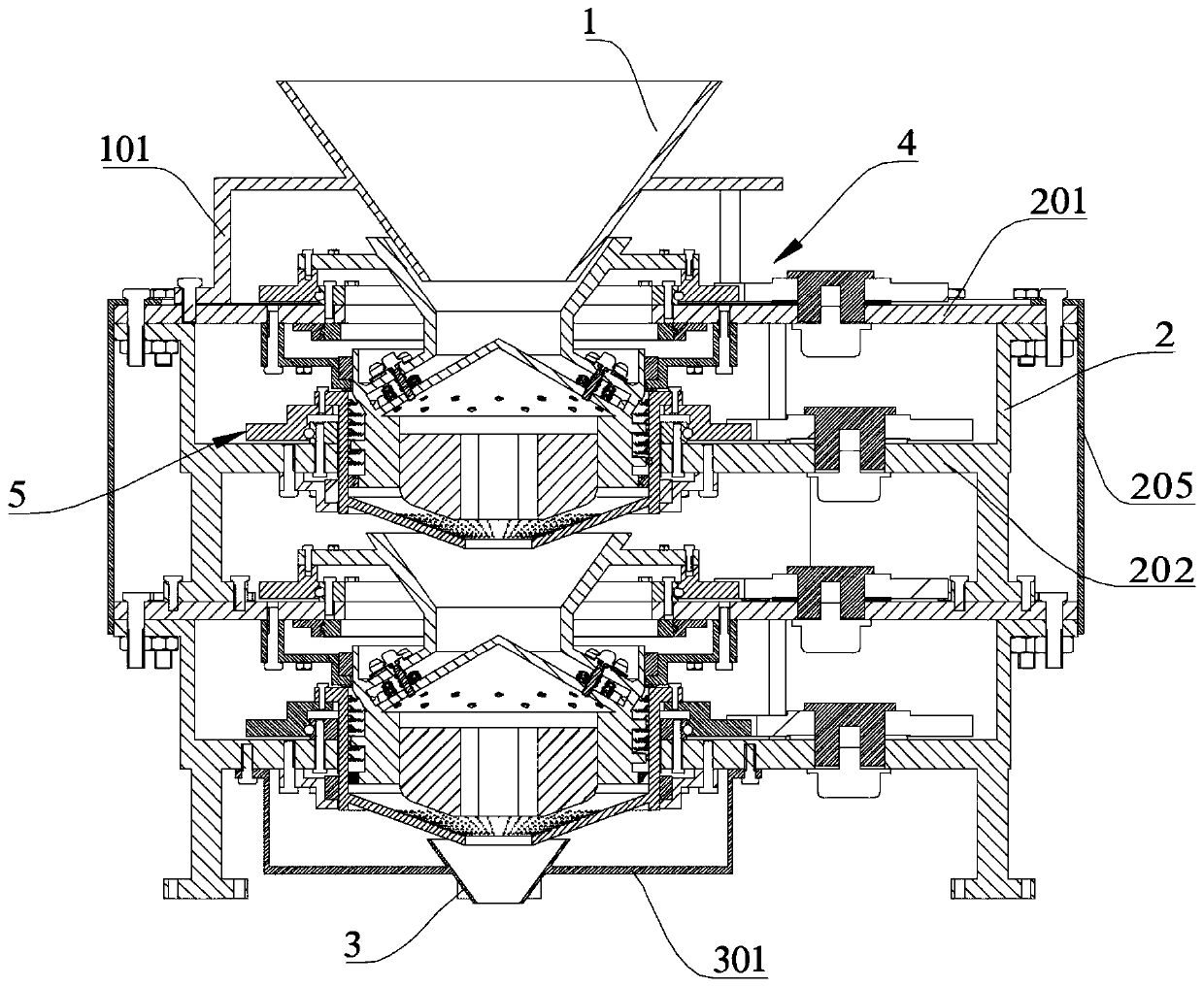

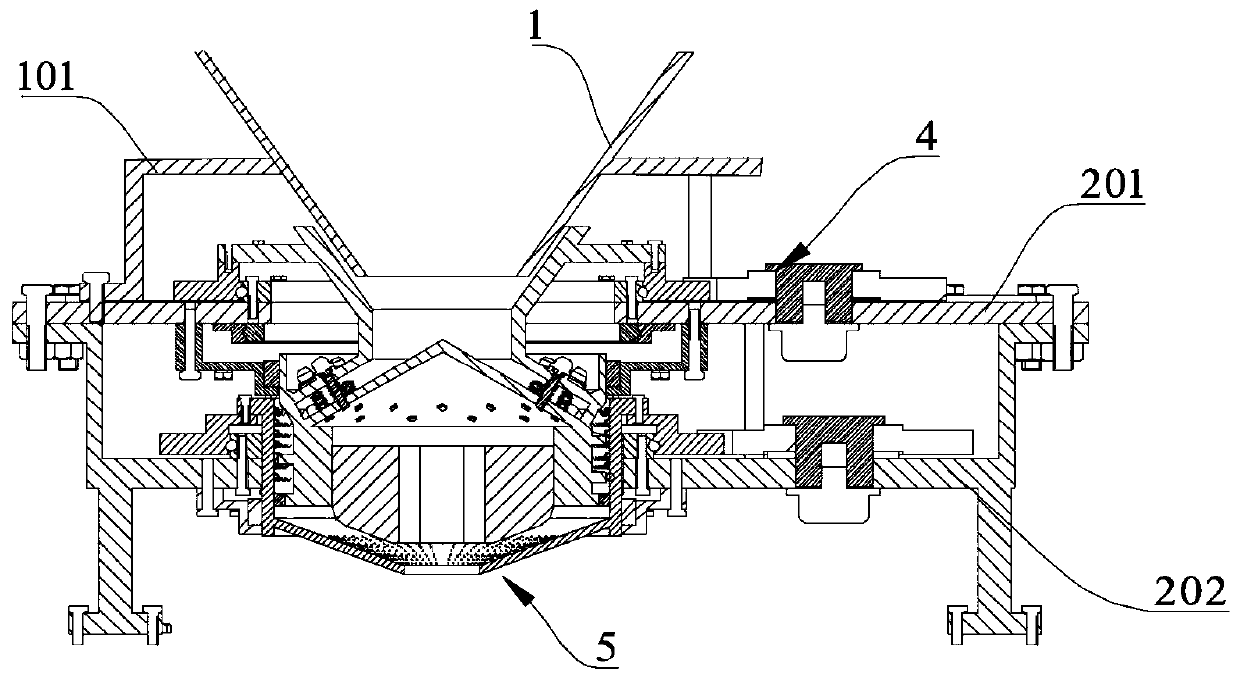

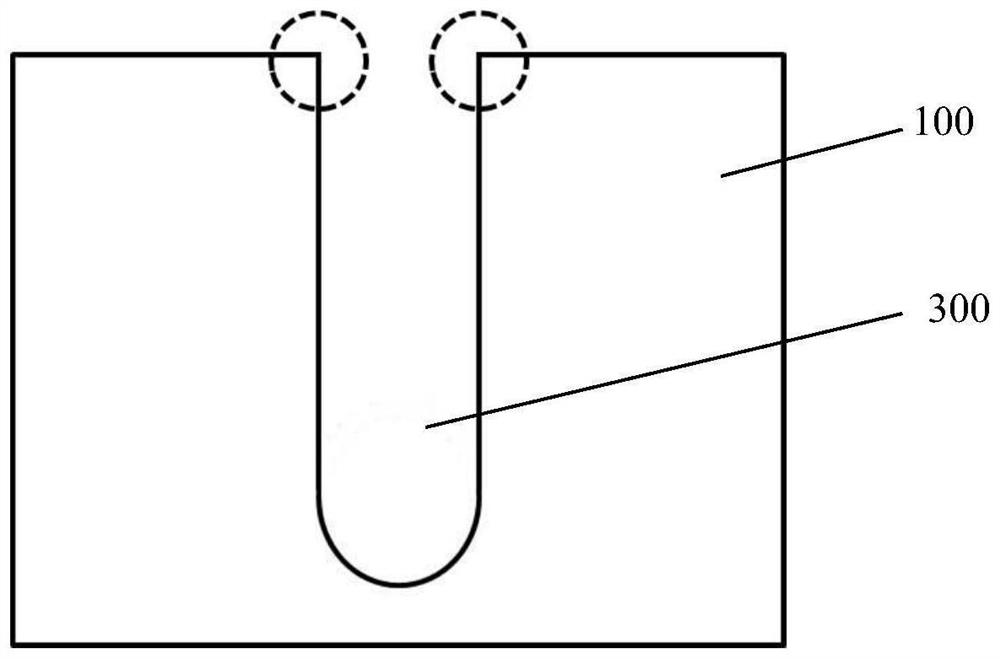

Shaping equipment for construction waste resource utilization recycled aggregate particles

InactiveCN111495510AEliminate sharp cornersFull blow wear impactGrain treatmentsConstruction engineeringStructural engineering

The invention discloses shaping equipment for construction waste resource utilization recycled aggregate particles. The shaping equipment comprises a feeding hopper and a discharging hopper, and a plurality of particle shaping equipment are sequentially installed in an equipment rack from top to bottom. Each particle shaping equipment is composed of a crushing device and a grinding device, whereinthe crushing device comprises a rotatable cone sleeve crushing device, the cone sleeve crushing device is composed of a cone sleeve and a grinding sleeve, and the grinding device comprises a roller rotatably mounted on a lower cover plate inside the equipment rack. According to the equipment, substances such as flat aggregate and cement attached to the surface of the aggregate can be eliminated,and sharp corners on the surface of the aggregate can be eliminated; and the upper and lower groups of particle shaping equipment are arranged, so that the aggregate is fully beaten, abraded and impacted, and the quality effect of aggregate treatment is guaranteed. Each crushing device is provided with a plurality of tooth shafts which rotate alternately to impact the aggregate to eliminate the flat aggregate, each cone sleeve and each roller rotate reversely at a high speed, and crushing and shaping are realized through multiple collision friction.

Owner:高淑兰

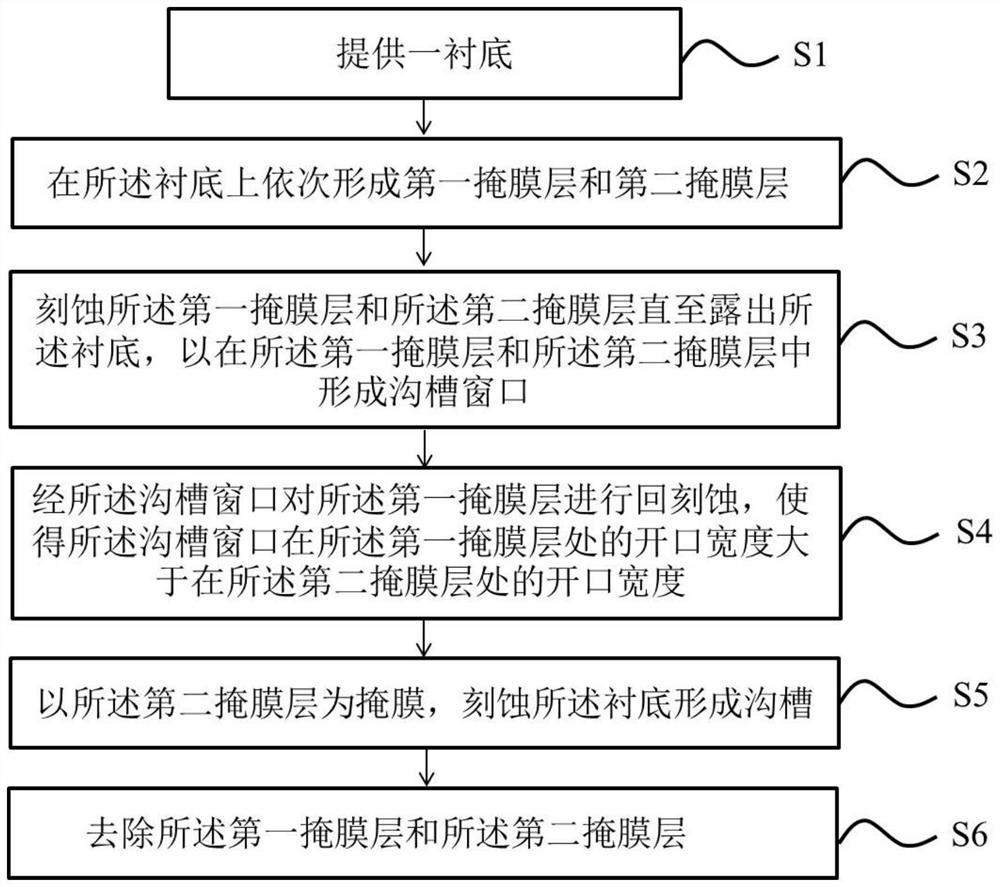

Method for rounding top corner of groove and semiconductor structure

PendingCN113707553AEliminate sharp cornersExcellent rounding effectSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureEngineering

The invention provides a method for rounding a top corner of a groove and a semiconductor structure. According to the method, the top corner of the groove is made to be always in an exposed state in a groove forming process through the back etching of a first mask layer next to a substrate, and the top sharp corner of the groove can be synchronously rounded in a groove etching process, so that the smooth and round top corner of the groove can be formed. With the method adopted, a sharp corner at the top of the groove is eliminated, the smooth and round top corner of the groove can be formed while the groove is etched, no independent rounding operation needs to be added, the whole method is simple in process, and the production cost is greatly reduced; and the first mask layer is subjected to back etching by adopting wet etching, so that the whole etching process is easier to control, the back etching amount can be more accurately controlled, and the subsequent rounding of the top corner of the groove is simpler and easier to control. According to the semiconductor structure with the groove top corner formed by the method, the electric leakage phenomenon can be effectively avoided, the breakdown voltage can be improved, and the reliability of the semiconductor structure can be ensured.

Owner:SIEN QINGDAO INTEGRATED CIRCUITS CO LTD

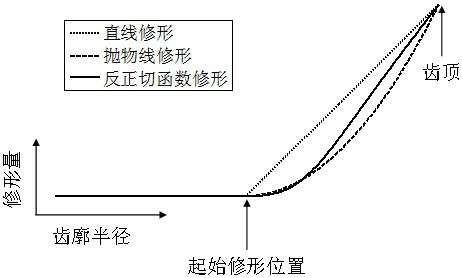

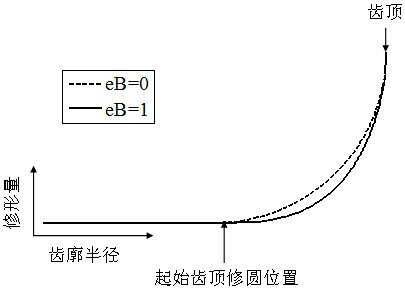

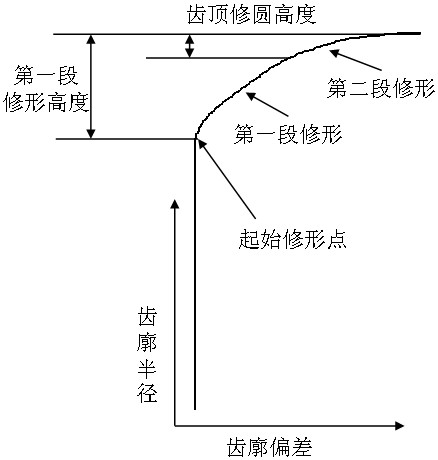

A gear modification method for reducing gear micropitting

The invention discloses a gear modification method for reducing gear micro-pitting. Through the first stage of modification, the smooth transition of the initial modification area can be realized, and the formation of micro-pitting in the alternate meshing area of single and double teeth can be reduced; The two-stage modification can realize the smooth transition of tooth top meshing and reduce the formation of micropitting in the meshing and meshing areas. The present invention can realize the parametric control of the modification curve by changing different modification parameters, which not only retains the advantage of straight line modification to remove more material, but also can realize the transition area between the involute and the modification curve and the modification curve and the tooth top Smooth transitions in circular transition areas. Through the selection of appropriate modification parameters, the pressure distribution characteristics during the tooth contact process can be well improved, and the service life and reliability of the gear can be improved.

Owner:BEIHANG UNIV

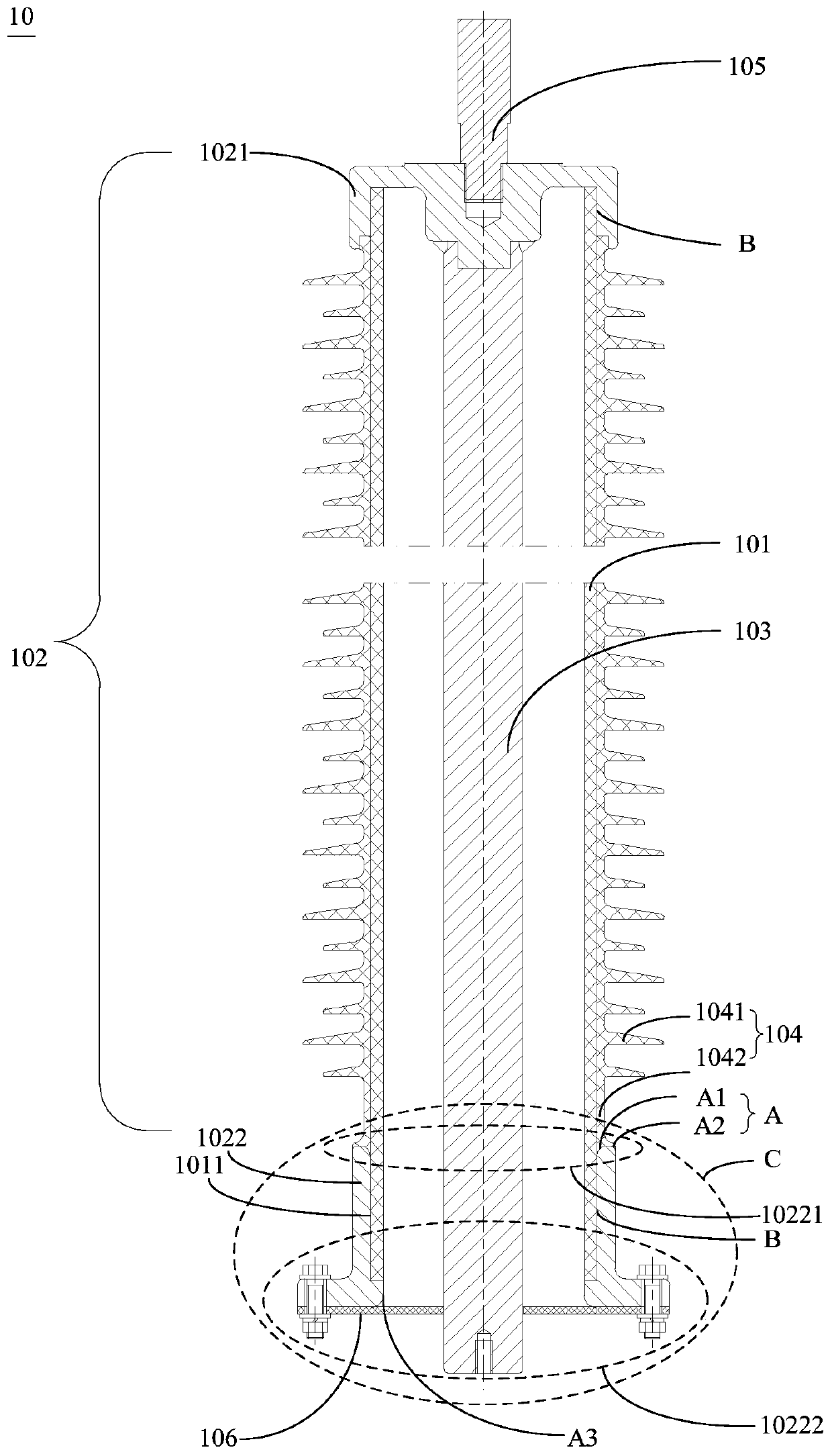

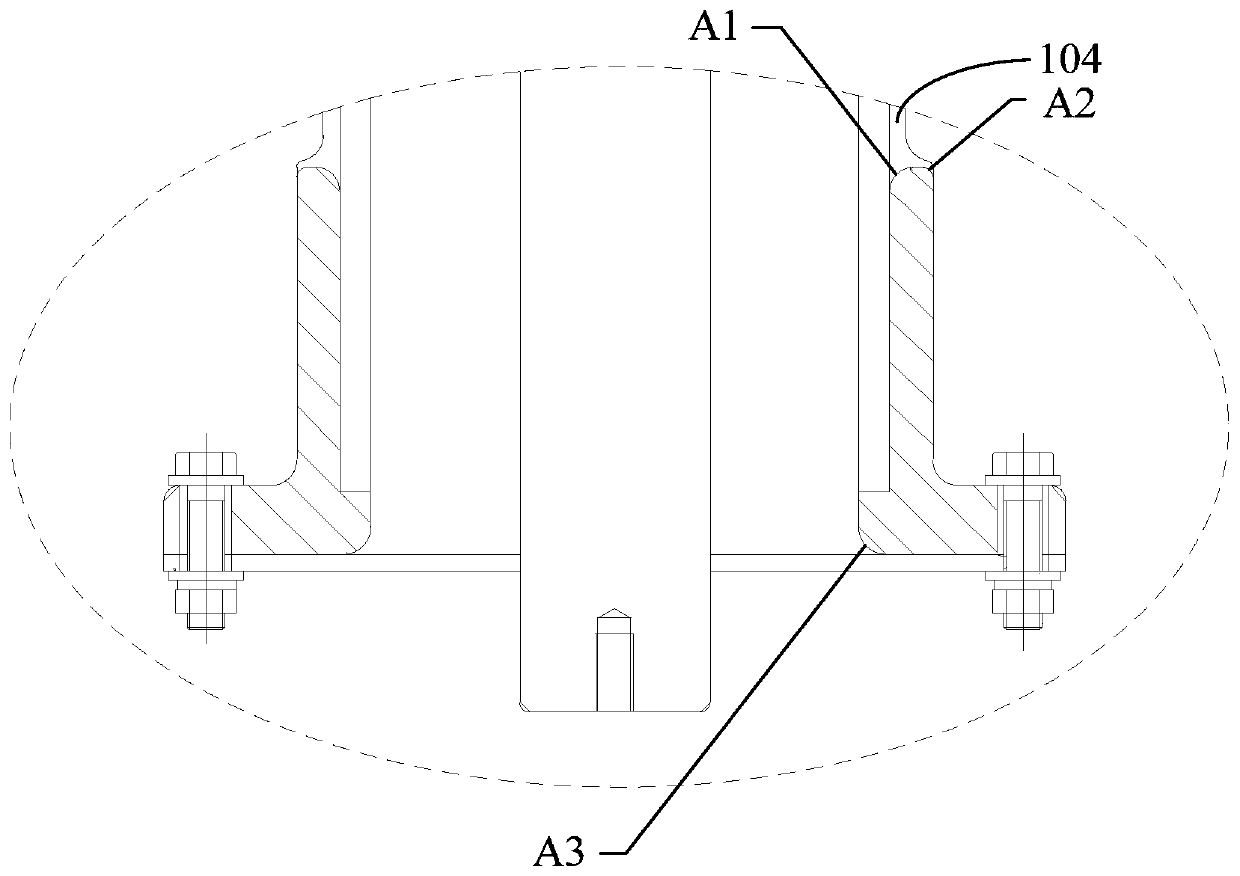

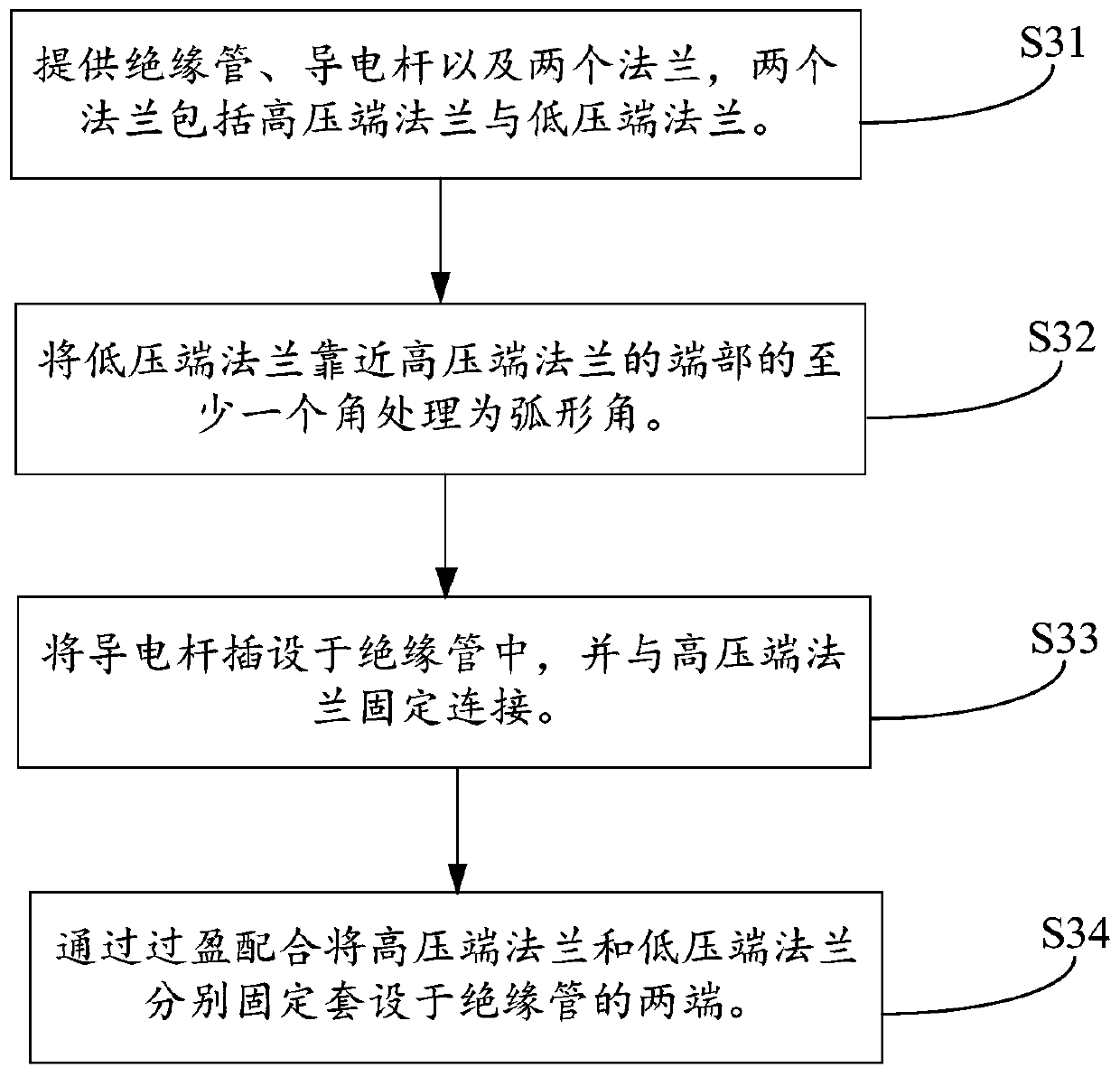

Insulating sleeve and manufacturing method thereof

InactiveCN109979695AEliminate sharp cornersUniform intensity distributionInsulating bodiesLow voltageEngineering

The invention discloses an insulating sleeve and a manufacturing method thereof. The insulating sleeve comprises an insulating tube, two flanges and a conducting rod, wherein the two flanges comprisea high-voltage end flange and a low-voltage end flange which respectively fixedly sleeve the two ends of the insulating tube; and the conducting rod is fixedly connected with the high-voltage end flange and is inserted into the insulating tube; and at least one angle, close to the end portion of the high-voltage end flange, of the low-voltage end flange is an arc angle. In this way, the low-voltage end flange is uniform in distribution of the intensity of an electric field with no need for arrangement of a metal shielding electrode to simplify the structure of the insulating sleeve, reduce thesize of the product and reduce the process difficulty.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

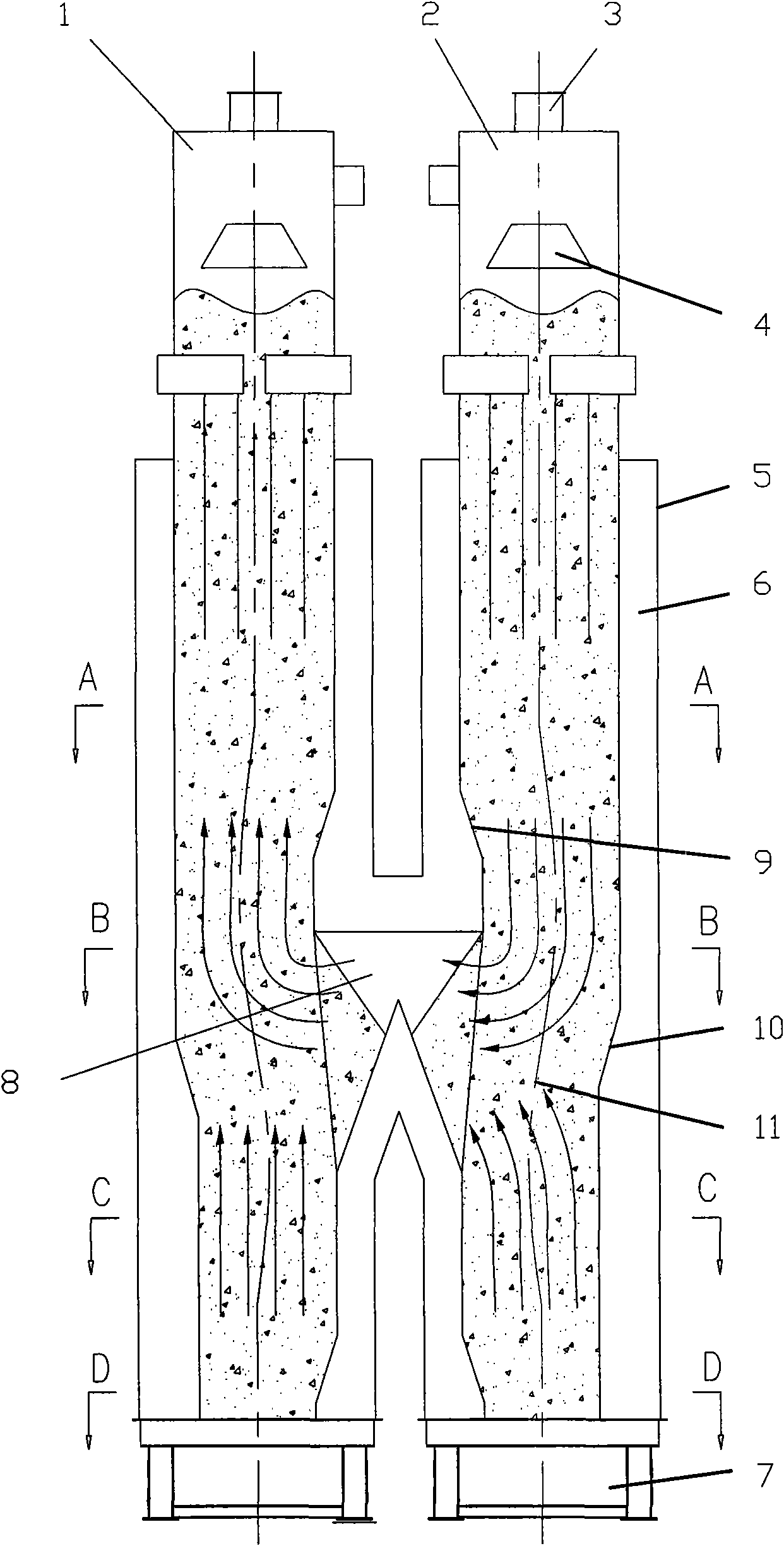

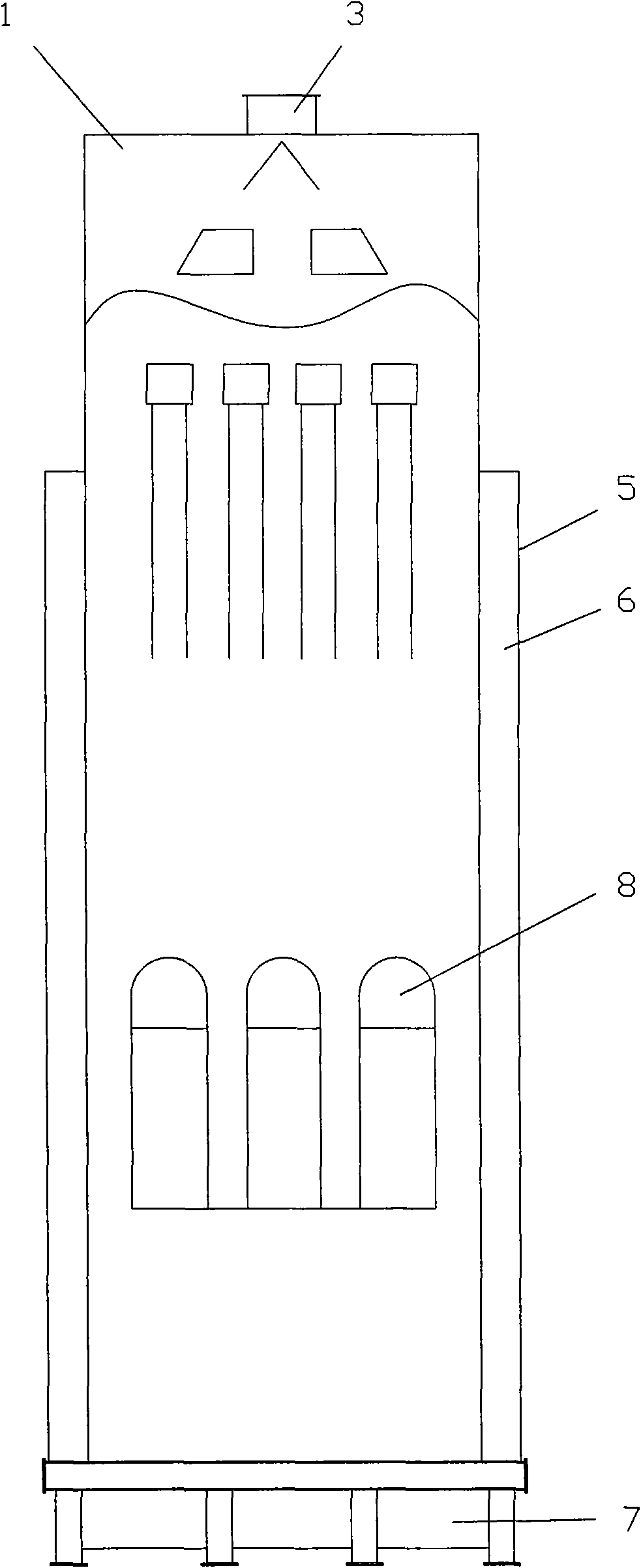

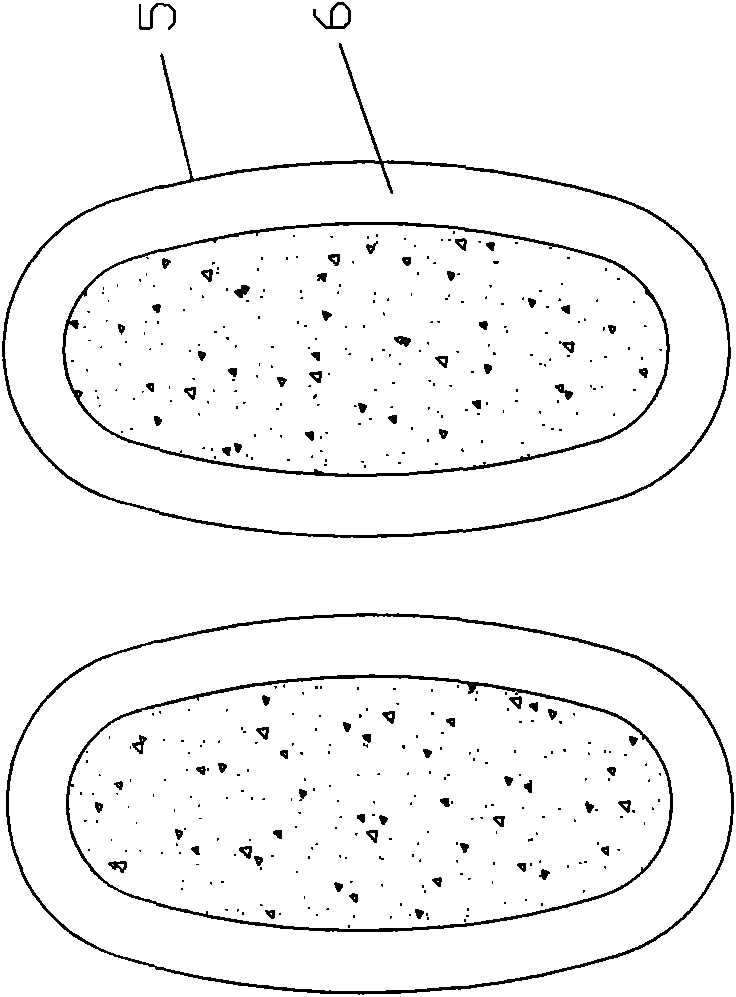

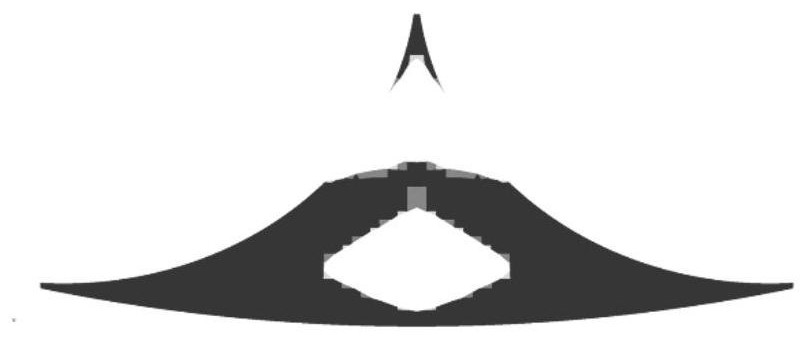

Curved-chamber kiln

The invention relates to a curved-chamber kiln, in particular to the curved-chamber kiln for calcining massive ore such as limestone, dolomite and the like. The curved-chamber kiln comprises two kilncylinders, each kiln cylinder comprises a feeding device, a fuel spraying gun, a kiln shell, a bricklaying layer and a discharging device from top to bottom, the two kiln cylinders are connected by asmoke channel, and the curved-chamber kiln is characterized in that the cross section of each bricklaying layer of each kiln cylinder is oblate; the upper insides of the smoke channel in the middle part of the kiln cylinders are respectively provided with an outward guiding wind slope, and the lower outsides of the smoke channel in the middle part of the kiln cylinders are respectively provided with an inward dragging wind slope; and the kiln cylinders between the guiding wind slopes and the dragging wind slopes become narrow in the left-right direction. The curved-chamber kiln has the advantages of small cavity width, good calcining quality and easy operation.

Owner:XINXING HEBEI ENG & RES INC

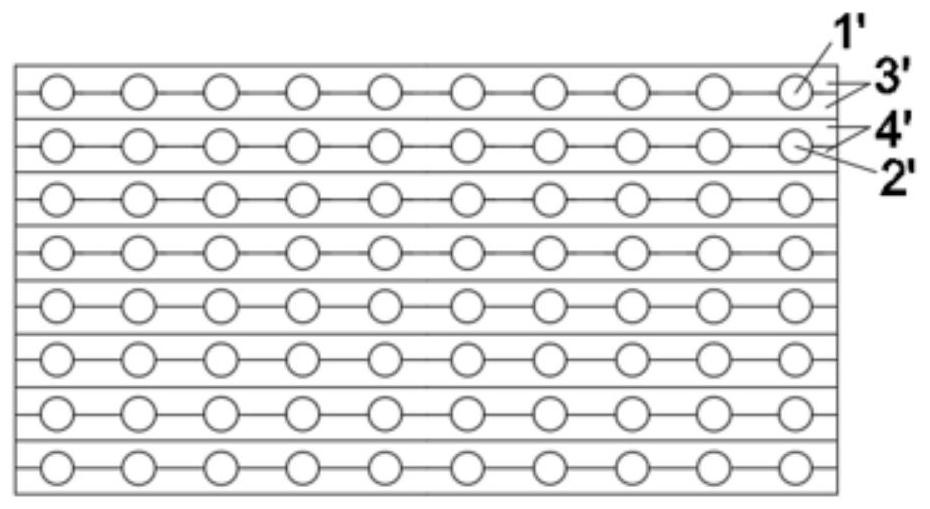

Umbilical cable filling structure optimization method

PendingCN111859588AUniform loadReduce weightGeometric CADDesign optimisation/simulationGeometric modelingEngineering

The invention discloses an umbilical cable filling structure optimization method. The method comprises: establishing a geometric model of an umbilical cable according to a filling shape of the umbilical cable, setting a pressure threshold value borne by each filling edge, simulating a stress characteristic of a filling component, and meanwhile, carrying out fixed constraint on each end point to limit translation and rotation in a model plane; carrying out topological optimization on the filling structure by adopting a variable density method; taking the density of each unit as a topological design variable, taking static flexibility minimization as a target function and a constraint function, selecting a volume fraction upper limit, setting an upper limit initial value, then carrying out optimization iterative calculation, adjusting the volume fraction upper limit according to a calculation result, and recalculating according to an adjusted numerical value to obtain an optimized structure; and carrying out curve fitting on the optimized structure, specifically, removing sharp corners and interrupted parts with small loads on the outer boundary according to the stress characteristics of the component, and fitting sawtooth-shaped boundaries in the structure to be smooth.

Owner:HARBIN ENG UNIV

Anti-glare processing method for glass display screen of electronic product

ActiveCN104829140BEliminate sharp cornersGood optical performanceFlexible article cleaningCleaning using toolsLiquid jetMegasonic cleaning

The invention provides an anti-glare processing method for a glass display screen of an electronic product, belonging to the technical field of display screen processing technology. It solves the technical problems of poor surface quality, bad hand feeling and weak anti-glare ability of the anti-glare glass manufactured by the anti-glare processing method of the existing display screen. In this anti-glare processing method, the glass display screen is put into a cleaning tank for cleaning and dust removal, and then put into an ultrasonic cleaning machine for ultrasonic cleaning; a corrosion-resistant plastic protective film is pasted on the four sides and the back of the glass display screen; Heat the frosting liquid to 20°C-26°C, put the glass display in the frosting liquid and soak for 60-120 seconds; remove the protective film on the glass display; put the polishing liquid into the jet machine, and put the glass display The screen is fixed, and the polishing liquid is sprayed to the front of the glass display screen through the nozzle of the jetting machine, and the spraying time is 180-300 seconds. The invention adopts a unique high-pressure jet polishing method to eliminate these microscopic sharp corners and improve the anti-glare ability.

Owner:ZHEJIANG XINGXING TECH CO LTD

A process integration method for improving flash memory cells

ActiveCN107887390BImproved Process Integration MethodsEliminate sharp cornersSolid-state devicesSemiconductor devicesEngineeringSilicon oxide

The invention proposes a method for improving the process integration of flash memory cells, including: device ion implantation to form a substrate structure; sequentially depositing a flash memory oxide layer, a floating gate polysilicon layer and a silicon nitride layer; forming a shallow trench isolation structure and depositing an oxide layer therein. Silicon layer: perform pre-cleaning treatment, etch to remove part of the silicon nitride layer and part of the silicon oxide layer in the shallow trench isolation structure, exposing the floating gate polysilicon sharp corner; oxidize the exposed floating gate polysilicon sharp corner to make the sharp corner smooth Carry out etching treatment to remove part of the silicon oxide layer in the shallow trench isolation structure, and simultaneously remove the silicon oxide used for rounding the corners of the floating gate polysilicon; etch and remove the silicon nitride layer until the floating gate polysilicon is exposed layer. The present invention utilizes the increased silicon oxide to advance the rounding of the sharp corners of the floating gates, and at the same time realizes the rounding of the sharp corners of the floating gates and the undamaged flash memory cells on the top of the floating gates of the flash memory cells, so as to provide continuous shrinkage of flash memory Cells provide another way to optimize.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

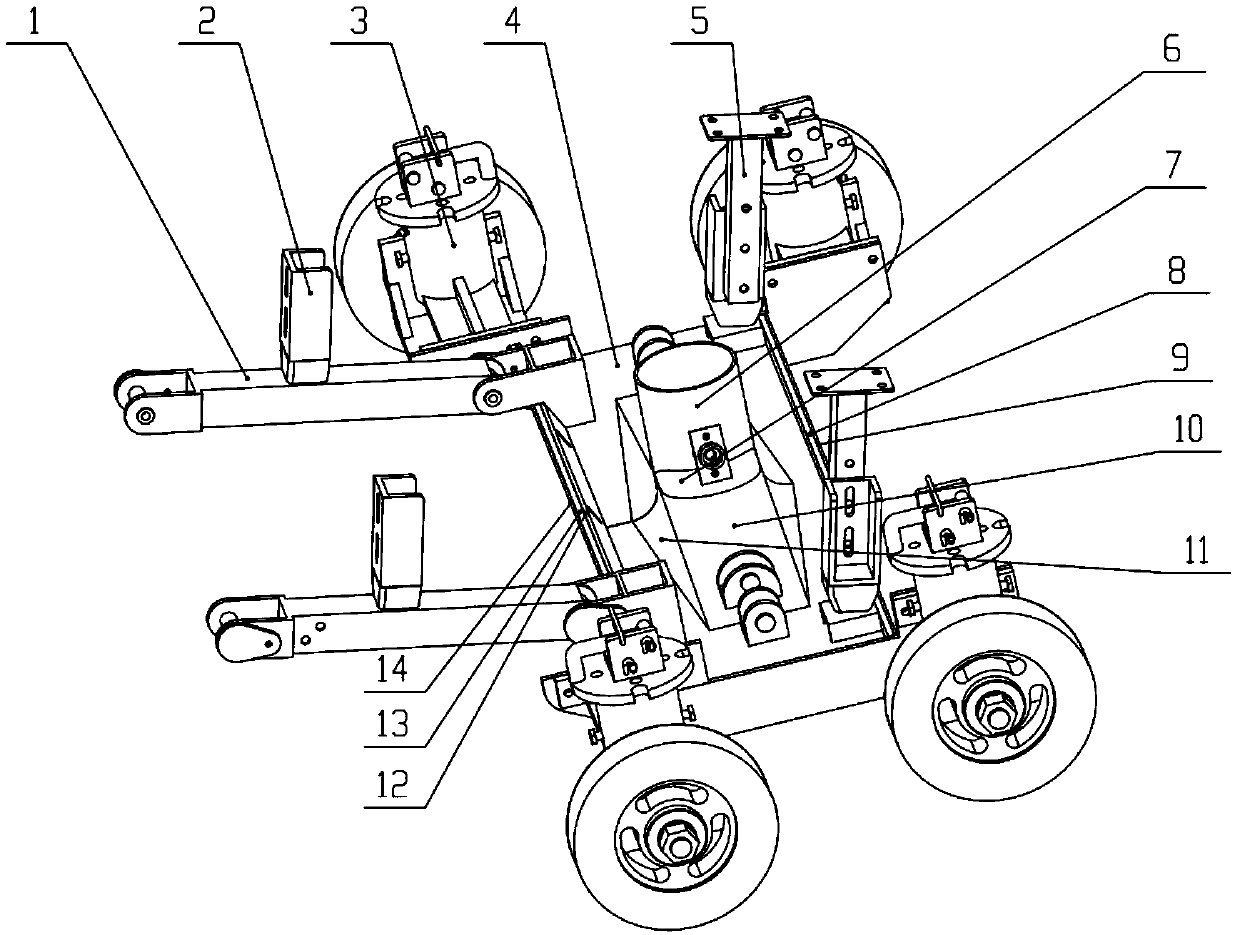

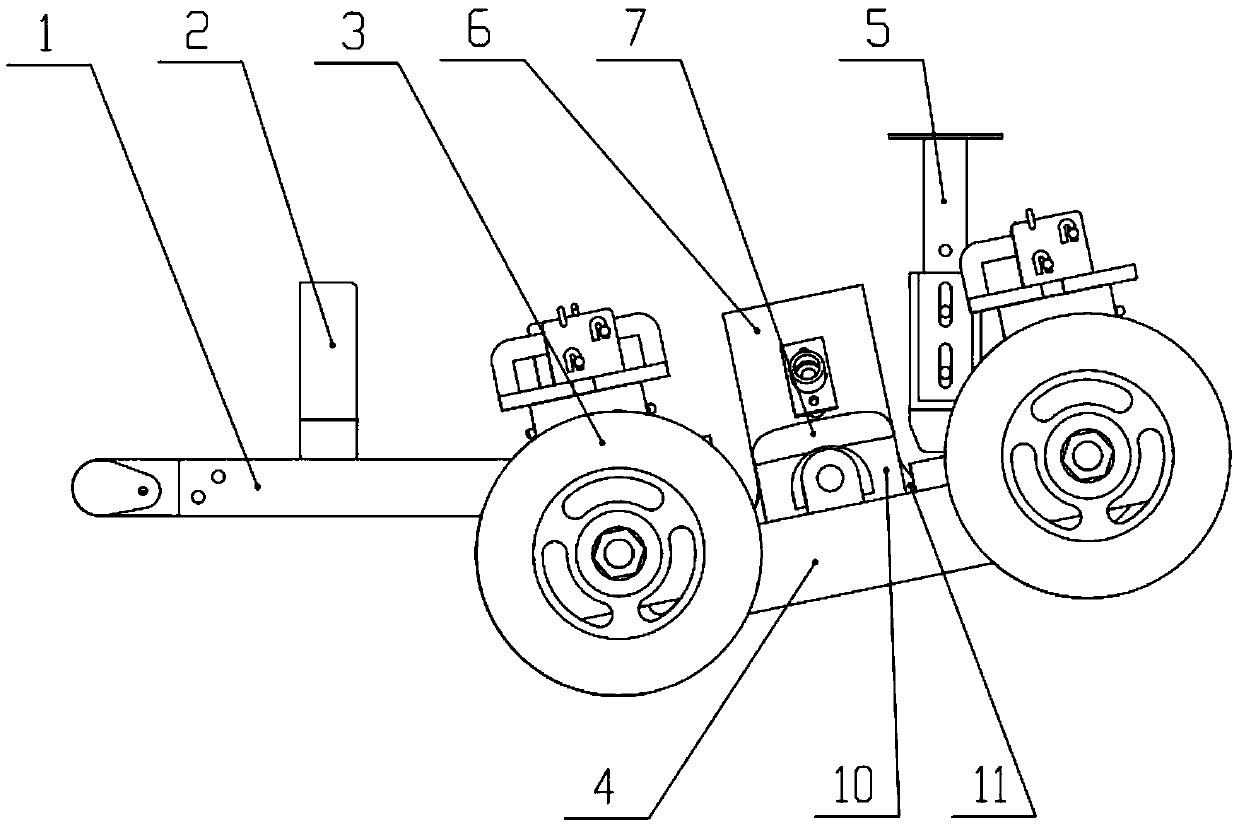

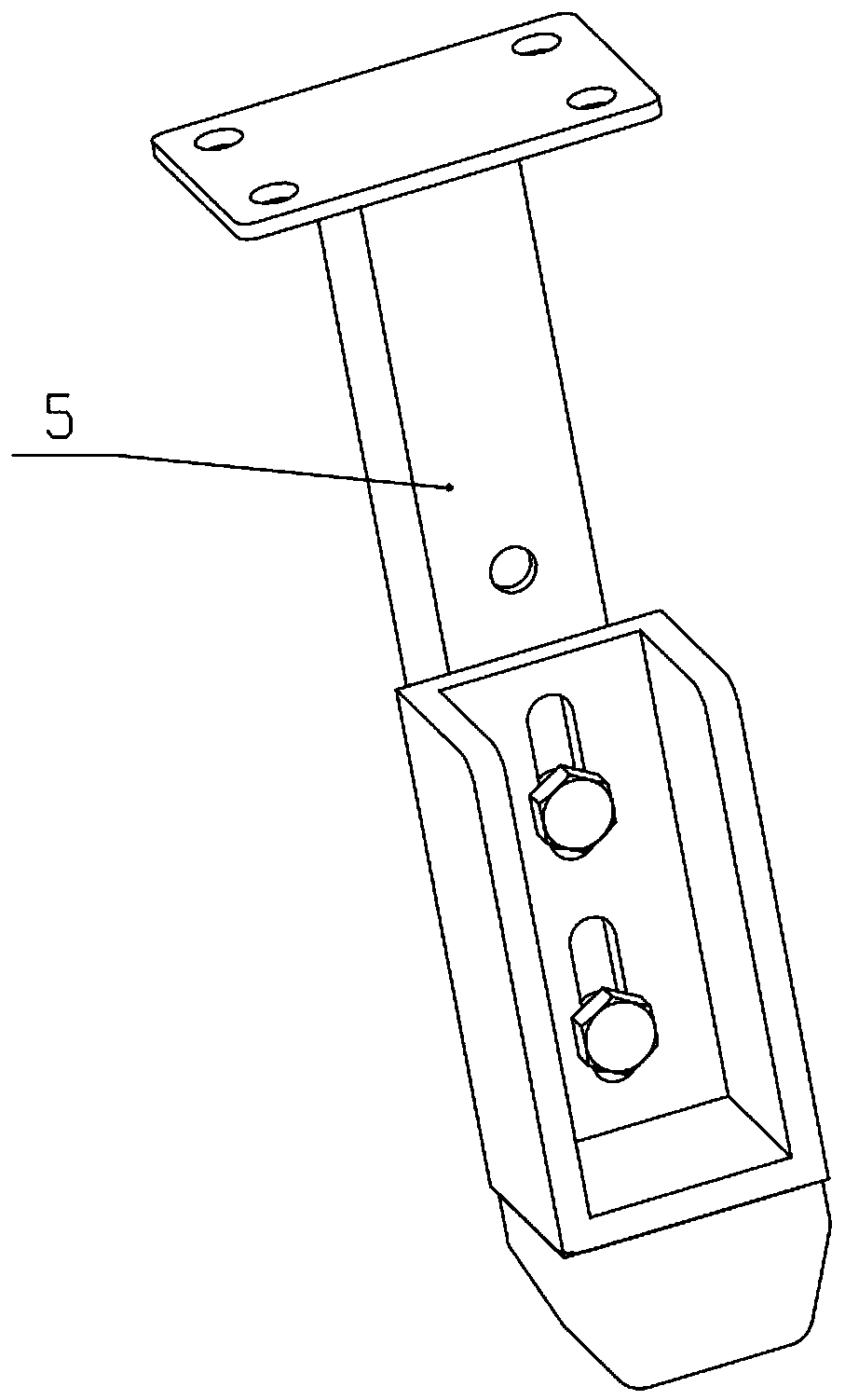

Suction sweeper nozzle

Owner:WUHAN UNIV OF TECH

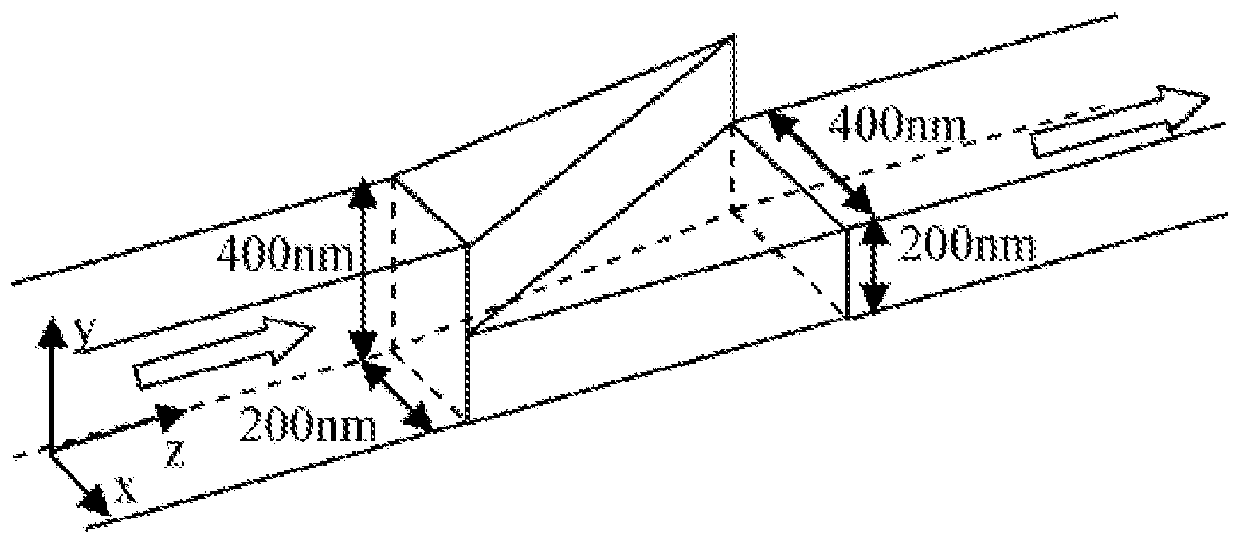

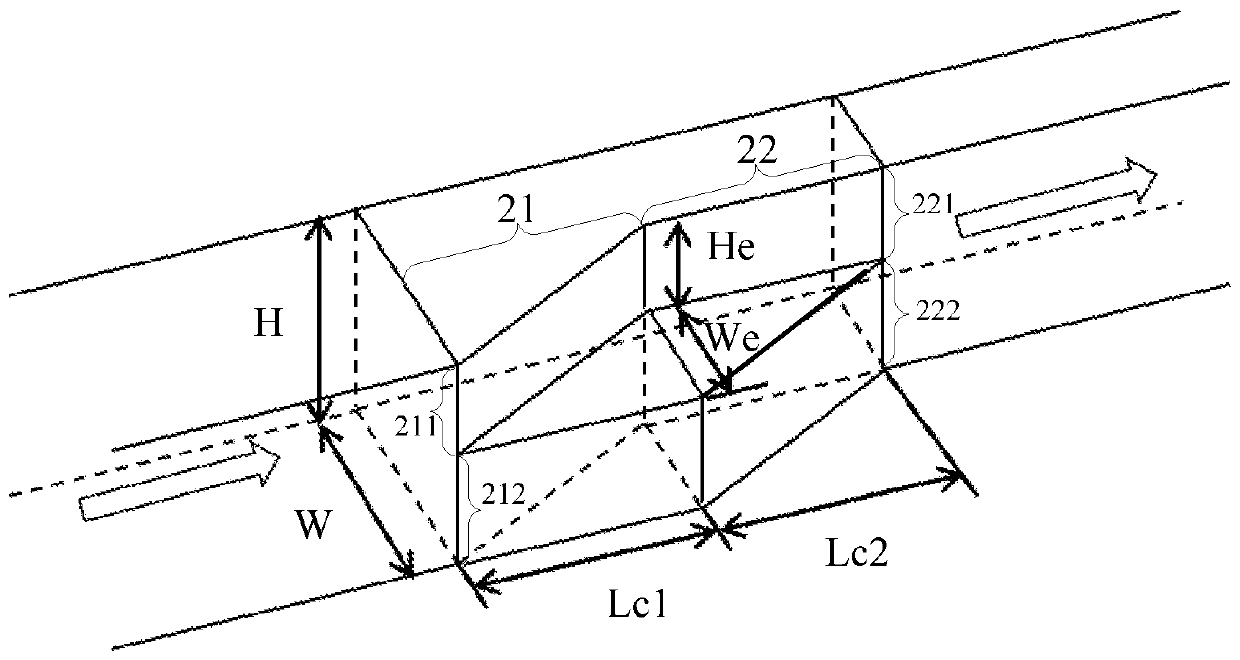

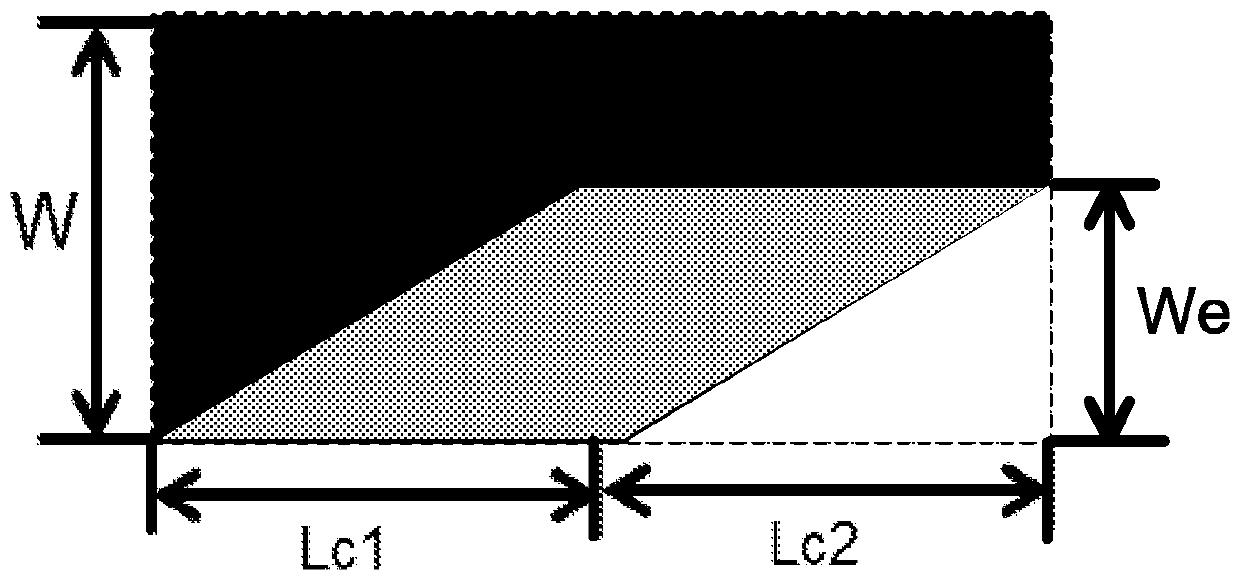

a polarization rotator

ActiveCN106461870BEliminate sharp cornersEasy to integrateCoupling light guidesWaveguidePolarization rotator

Disclosed is a polarization rotator (20), comprising a first stage waveguide (21) and a second stage waveguide (22). The second stage waveguide (22) and the first stage waveguide (21) are in cascade connection. The first stage waveguide (21) has the same thickness as the second stage waveguide (22). The first stage waveguide (21) comprises a first stage upper layer waveguide (211) and a first stage lower layer waveguide (212). In a direction from the first stage waveguide (21) to the second stage waveguide (22), the width of the first stage upper layer waveguide (211) gradually narrows from a first preset width (W) to a second preset width (W-We), while the first stage lower layer waveguide (212) keeps a consistent width. The second stage waveguide (22) comprises a second stage upper layer waveguide (221) and a second stage lower layer waveguide (222). The thickness of the second stage upper layer waveguide (221) is the same as that of the first stage upper layer waveguide (211), and in a direction from the first stage waveguide (21) to the second stage waveguide (22), the width of the second stage lower layer waveguide (221) gradually narrows from a first preset width (W) to a second preset width (W-We), while the second stage upper layer waveguide (221) keeps a consistent width. The structure of the polarization rotator (20) can be easily manufactured and implemented.

Owner:HUAWEI TECH CO LTD

Trapezoidal zone plate with quasi-single-stage focusing

InactiveCN105866870BSelf-supportingDoes not affect diffraction resultsDiffraction gratingsIsosceles trapezoidSingle stage

The invention discloses a trapezoidal wave zone plate with a quasi-single-stage focusing characteristic. The trapezoidal wave zone plate comprises a light-proof substrate and a plurality of ring-shaped wave zones which are sequentially arranged from inside to outside by taking the substrate as a center, wherein each ring-shaped wave zone comprises at least two spiral trapezoidal hole light transmission units which are formed by twisting isosceles-trapezoid-shaped hole light transmission units, and are sequentially connected; the radial light transmittance of the wave zone plate meets a formula shown in the description. Compared with a common Fresnel wave zone plate, the trapezoidal wave zone plate can restrain the diffraction efficiency of a senior focus very well, also can reduce the peak strength of the senior focus. Moreover, when a ratio of the top edge of the original trapezoid to the bottom edge of the original trapezoid is equal to 1 to 5, the trapezoidal wave zone plate further has the effect of eliminating a 3n-level focus, and also restrains the efficiency of a 5-level focus to 0.16% of a 1-level focus (insulating efficiency being 6.93%). Compared with a Gabor wave zone plate, the 1-level focus efficiency is higher than the focusing efficiency of the Gabor wave zone plate, and the trapezoidal wave zone plate is easier to manufacture in comparison with a plurality of binaryzation Gabor wave zone plates.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

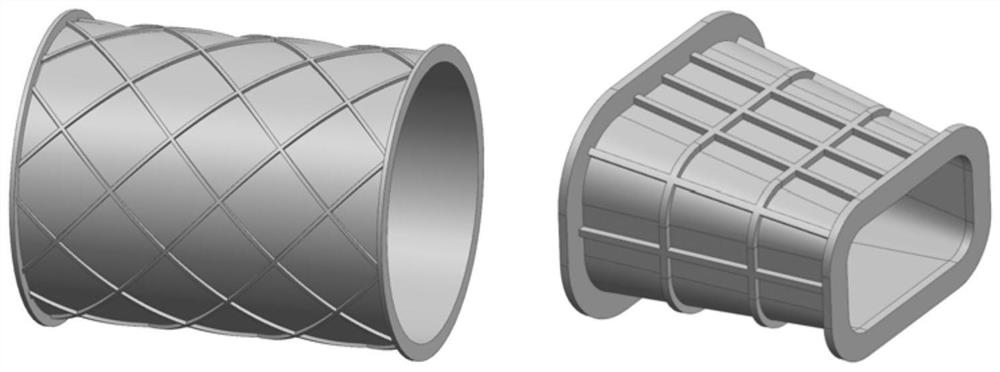

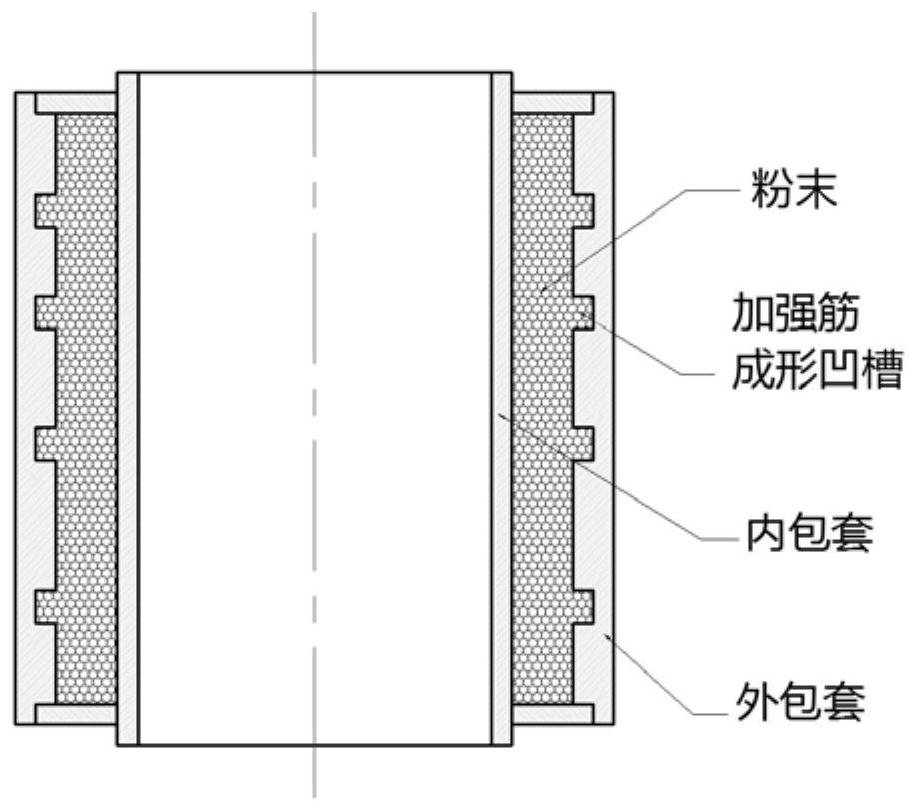

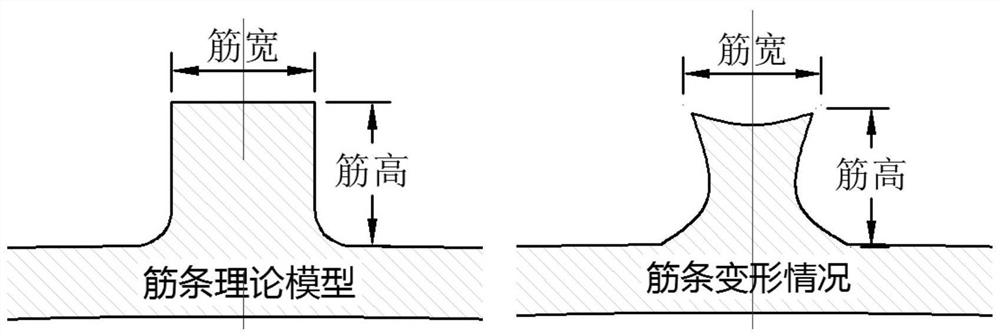

An Outer Cover and Method for Eliminating Dimension Deviation of Rib Structure in Powder Metallurgy Components

The invention discloses an outer sheath and method capable of removing size deviation of a rib structure in a powder metallurgical component. The outer sheath is of a groove structure containing ribs,the groove depth and the groove width are both larger than the theoretical height and the theoretical rib width of the ribs, the bottom plane and the side walls of the groove are in transition through an arc splicing structure, and the side walls of the groove incline outwards from the bottom. Through design of the reasonable outer sheath, a die groove is formed, and the problem that after the ribs are formed, secondary machining is needed is solved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Leakage current optimizing method for low-power-consumption product

ActiveCN106783583AEliminate sharp cornersAvoid leakage currentSemiconductor/solid-state device manufacturingAdhesivePoint change

The invention discloses a leakage current optimizing method for a low-power-consumption product. Photoresist is taken as a template to perform hard mask etching; adhesive removing is performed on a hard mask etching terminal point detection point; then the hard mask is used as a template, a low-bias-voltage-power, high-pressure and high-flow polymer gas is adopted; a smooth morphology on the top of a substrate base material is formed in a process of hard mask over etching, so that an etching switching point changed from the bottom of the hard mask to the top of the substrate base material in a transitional manner in a shallow trench etching process is changed; a sharp corner morphology caused by a conventional way of removing adhesive after hard mask is over-etched, and then etching the substrate base material is eliminated; and therefore, the smooth morphology is formed at the etching starting point on the top of the substrate, so that leakage current caused by a micro sharp corner morphology on the top of the shallow trench can be eliminated fundamentally.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

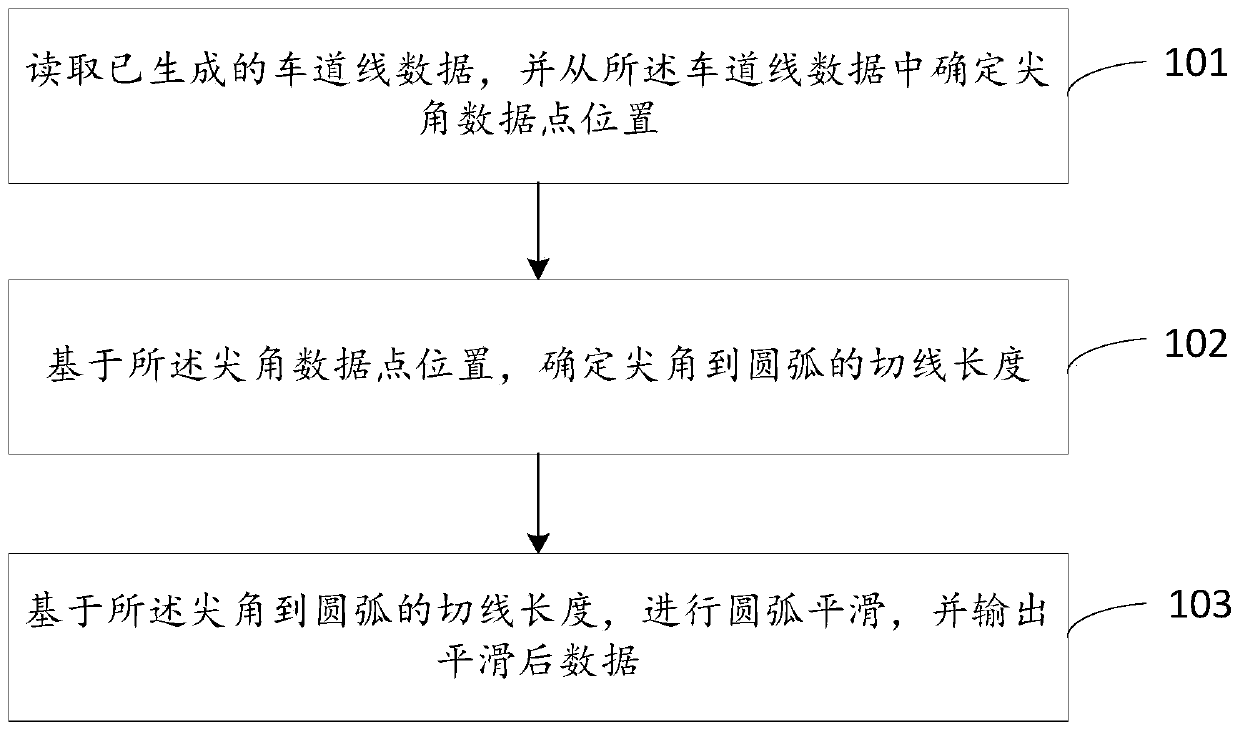

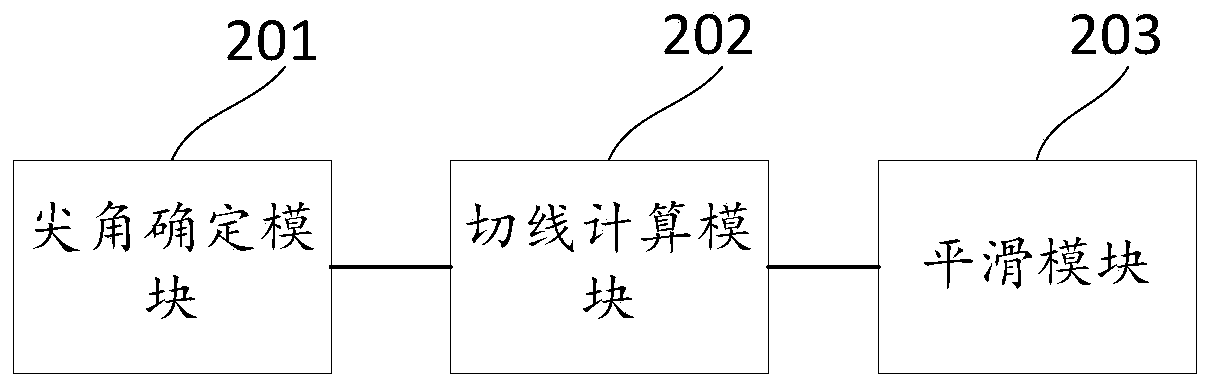

Lane line smoothing method and system

PendingCN111192216AEasy and fast to executeImprove robustnessImage enhancementImage analysisEngineeringPoint data

The embodiment of the invention provides a lane line smoothing method and system, and the method comprises the steps: reading generated lane line data, and determining the positions of sharp corner data points from the lane line data; determining the tangent length from the sharp corner to the arc based on the sharp corner data point position; and performing arc smoothing based on the tangent length from the sharp corner to the arc, and outputting the smoothed data. According to the lane line smoothing method and system, the sharp corner part in the lane line can be eliminated, the lane line feature shape points with good smoothness areobtained, better support is provided for subsequent vehicle guiding, and the method is easy, convenient and rapid to implement, high in robustness, capableof adapting to 2D and 3D lane line shape point data and capable of adapting to sharp corner scenes of various distances.

Owner:WUHAN ZHONGHAITING DATA TECH CO LTD

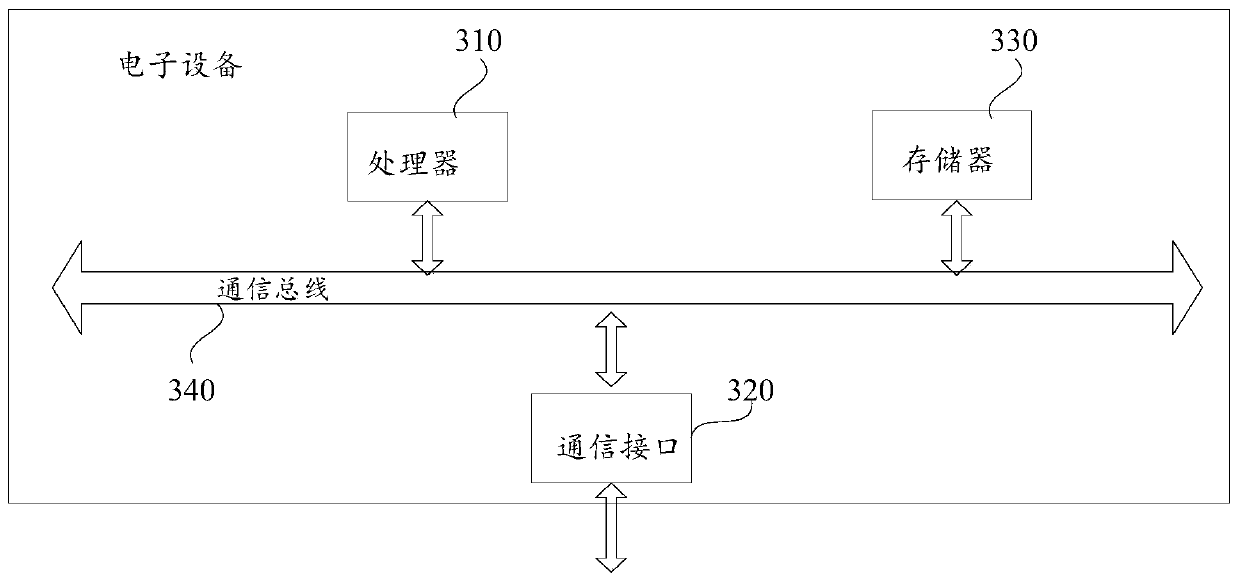

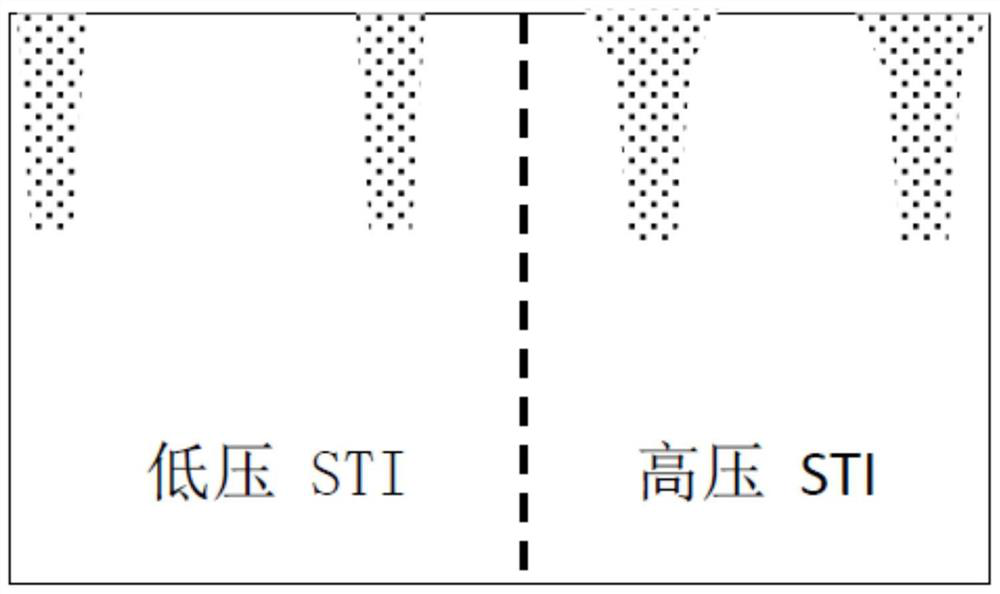

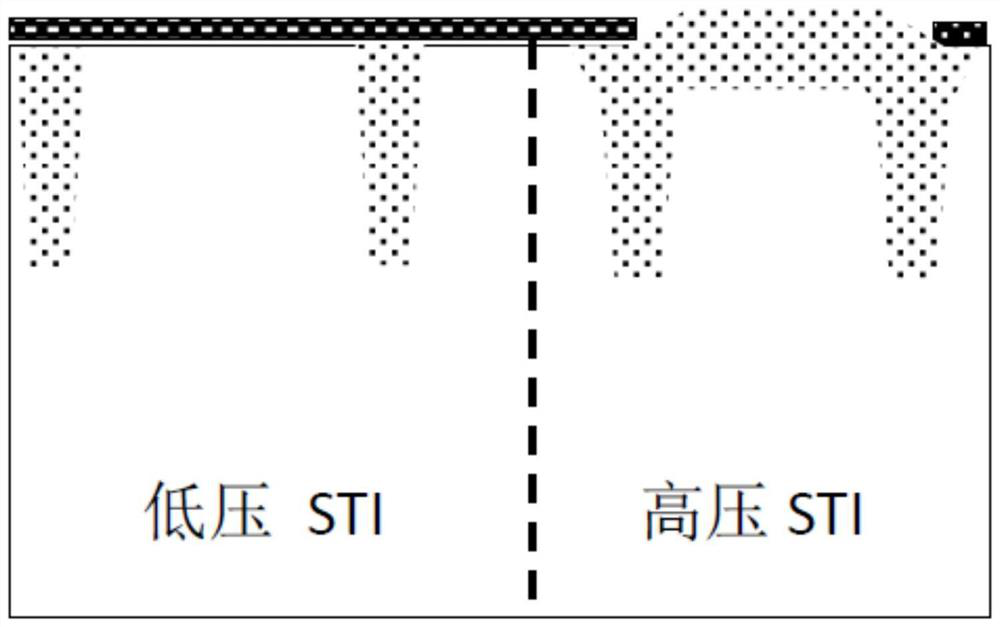

Manufacturing method of high-voltage thick gate oxide

ActiveCN112635316AImprove reliabilityImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesPhysical chemistryEngineering

The invention discloses a manufacturing method of a high-voltage thick gate oxide, and the method comprises the following steps of: depositing cushion silicon oxide on a silicon substrate, and depositing cushion silicon nitride on the cushion silicon oxide; carrying out shallow trench isolation photoetching, etching, silicon oxide filling and chemical mechanical grinding; sequentially depositing mask silicon nitride and mask silicon oxide on a silicon wafer; removing the mask silicon oxide and the mask silicon nitride in ae high-voltage thick gate oxide region through photoetching and etching processes, and reserving the cushion silicon nitride between the two shallow trench isolations in the high-voltage thick gate oxide region; carrying out first thermal oxidation growth to passivate the shallow trench isolation corner of the high-voltage gate oxide region; removing the cushion silicon nitride between the two shallow trench isolations of the high-voltage thick gate oxide region; and carrying out second thermal oxidation growth to generate the high-voltage thick gate oxide. The thick gate oxide and the STI corner gate oxide of the high-voltage device manufactured by the manufacturing method of the high-voltage thick gate oxide are thickened, passivated and smooth, the STI sharp corner problem can be eliminated, the reliability of the high-voltage thick gate oxide and the performance of the high-voltage device are improved, the process is simple, and the cost is low.

Owner:HUA HONG SEMICON WUXI LTD

A Method for Eliminating Sharp Angles at the Top of Groove

ActiveCN103137483BSpeed up etchingEliminate sharp cornersSemiconductor/solid-state device manufacturingHelix-destabilizing proteinsCompound (substance)

The invention discloses a method for eliminating a shaft corner at the top end of a groove. The method comprises the steps of 1, enabling oxide-nitride-oxide (ONO) to grow, 2, enabling the ONO to be etched, 3, enabling the groove to be etched, wherein the ONO serves as hard mask for dry etching, 4, enabling middle silicon nitride of the hard mask to be etched by a transverse wet method, wherein the sharp corner at the top end of the groove is required to be exposed completely, 5, enabling top layer oxidation film remained on the hard mask to be etched in a complete mode, and meanwhile enabling bottom oxidation film of the hard mask to be etched in transverse mode, 6, conducting homodromous etching at the bottom of the groove, and meanwhile conducting transverse etching and vertical etching for the sharp corner at the top end of the groove so as to reduce the sharp corner at the top end, 7, enabling a sacrificed oxide layer to grow inside the groove, enabling the sharp corner at the top end of the groove to be completely oxidized and to be disappeared, 8, enabling the sacrificed oxide layer to be etched in the wet method, enabling the silicon nitride to be etched in the wet manner, and keeping part of the silicon nitride serving as a barrier layer for helix destabilizing protein (HDP) chemical mechanical lapping. According to the method for eliminating the shaft corner at the top end of the groove, the sharp corner at the top end of the groove can be eliminated, and the fact that trailing HDP can fill the groove without holes is guaranteed.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

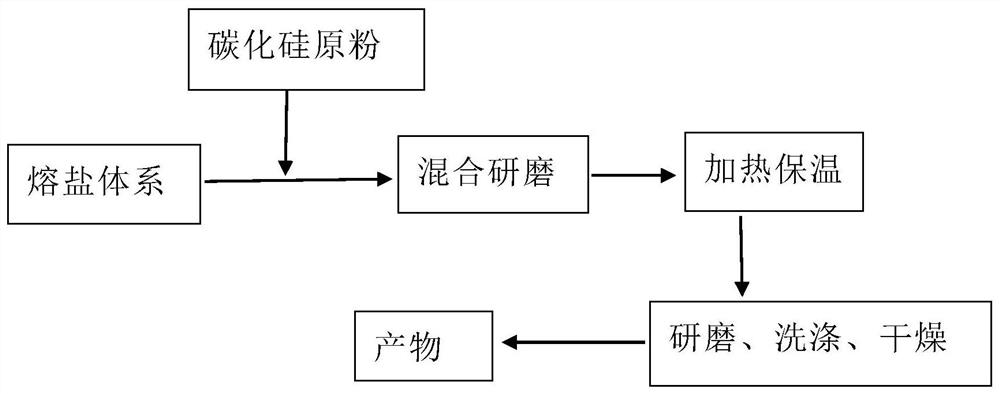

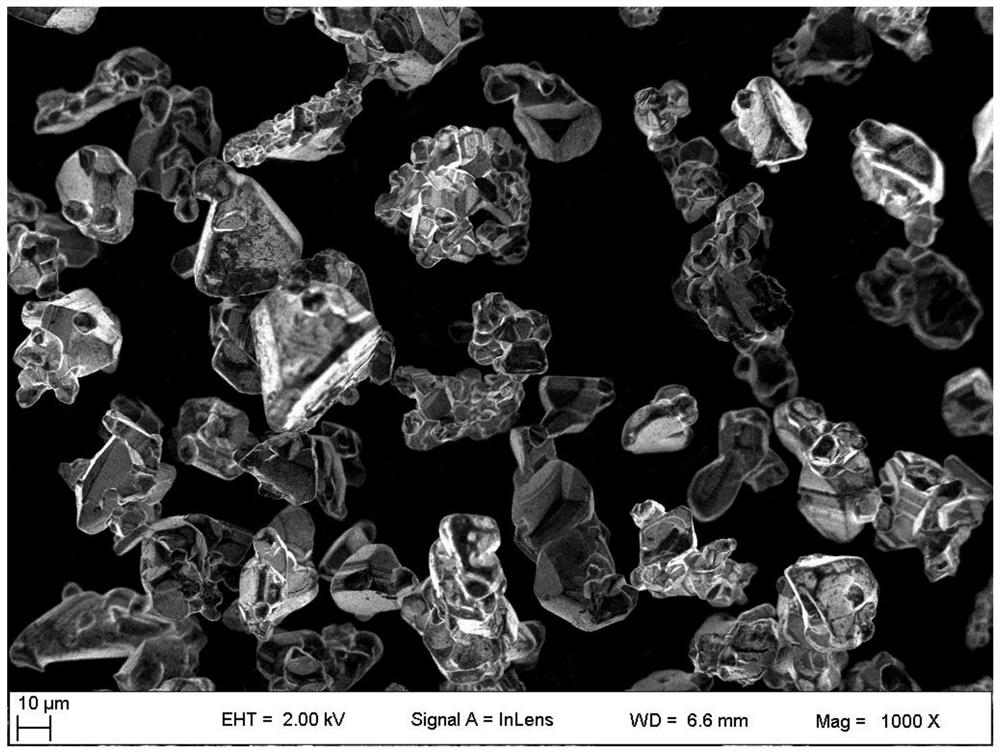

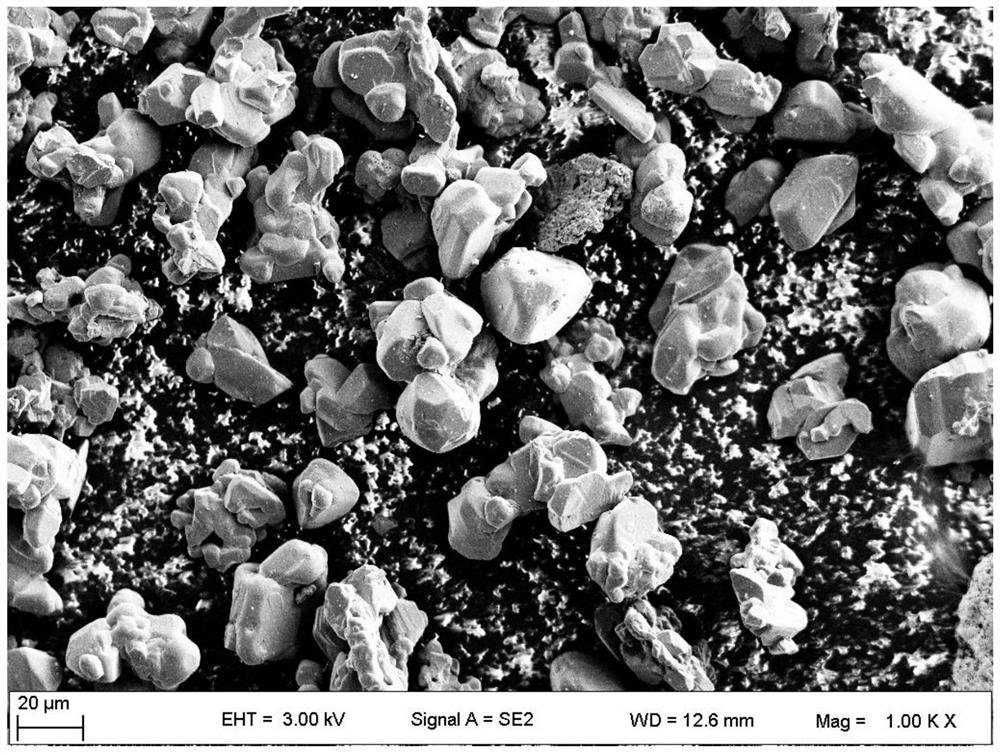

Shaping method of silicon carbide powder particles

PendingCN113264527AEliminate sharp cornersAvoid reunionSilicon carbideCarbide siliconInorganic salts

The invention discloses a shaping method of silicon carbide powder particles. The method comprises: 1, mixing a soluble inorganic salt and silicon carbide raw powder, grinding, and drying to obtain a mixture; 2, making the mixture heated to the temperature above the fused salt eutectic melting temperature to obtain a melt; and 3, cooling the melt to room temperature, grinding, washing and drying to obtain shaped silicon carbide powder particles. According to the method, soluble inorganic salt is heated and subjected to heat preservation to form liquid-phase molten salt, and the liquid-phase molten salt penetrates through powder particles of silicon carbide raw powder, so that agglomeration and accumulation of the silicon carbide powder particles are prevented, sharp corners of the powder are eliminated, the silicon carbide particles gradually become spheroidized in shape, shaping of the silicon carbide powder particles is achieved, powder crushing and reunion and the introduction of impurities are avoided, the shaping effect is improved, and the product quality is ensured; the process is simple and relatively easy to control; and the shaped silicon carbide powder is regular in particle structure, smooth in surface, uniform in size and good in shaping effect.

Owner:XIAN BOER NEW MATERIAL CO LTD

A three-screw screw with circular arc correction tooth shape

ActiveCN106122005BExtend working lifeStable Volumetric EfficiencyRotary piston pumpsRotary piston liquid enginesCircular discWorking life

Owner:黄山工业泵制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com