Negative part structure of magnetron

A magnetron and cathode technology, applied in the field of magnetron, can solve the problems of shortening the service life of magnetron, damage of magnetron, low radiation rate, etc., to prolong the normal working life, avoid high voltage breakdown, eliminate sharp corner effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

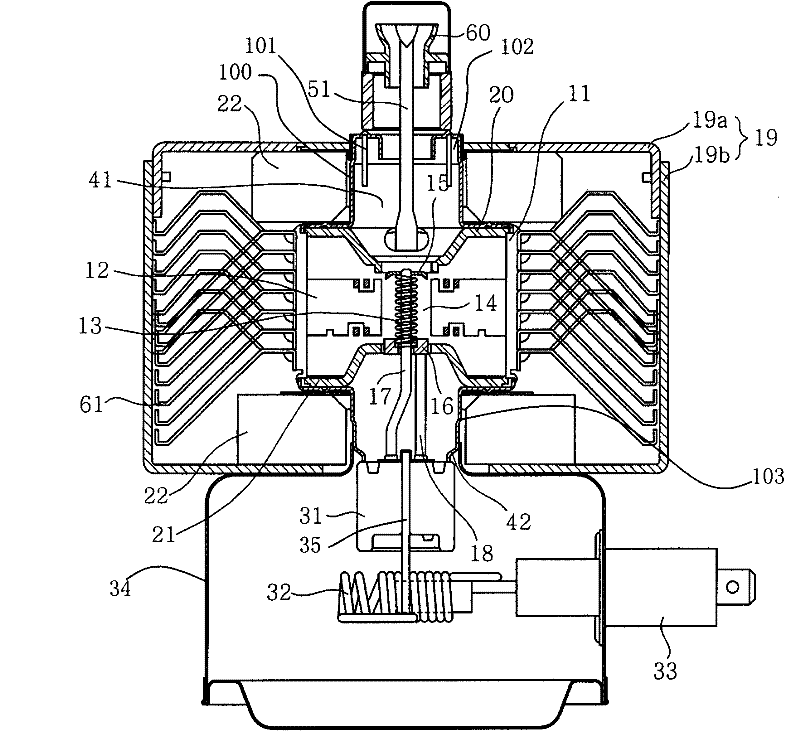

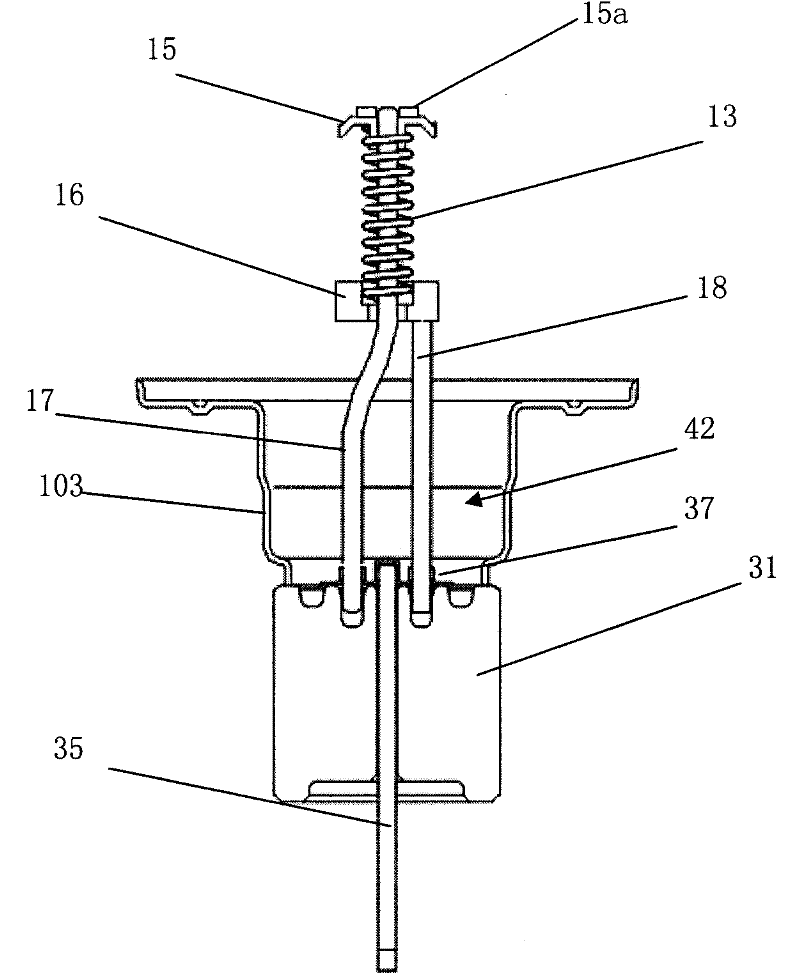

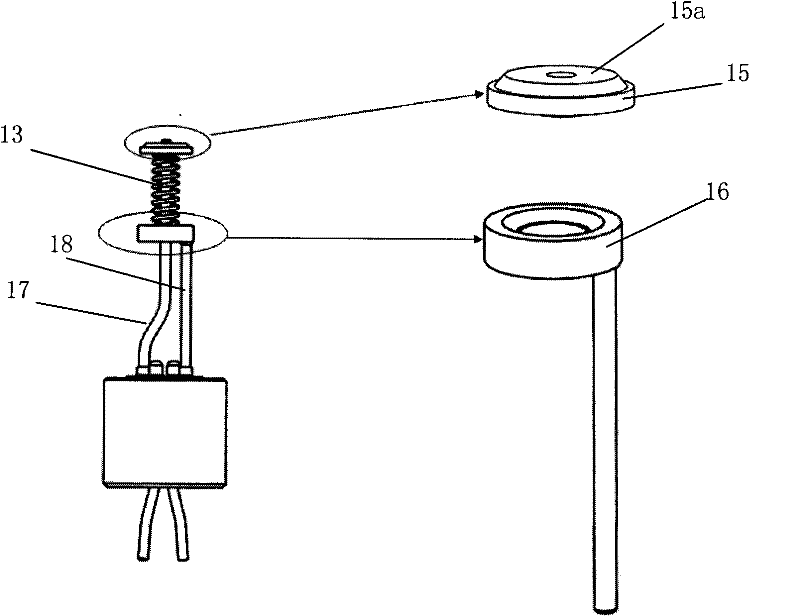

[0034] Figure 4 It is a schematic diagram of the structure of the cathode part of the magnetron of this invention.

[0035] Such as Figure 4As shown, the cathode cover of the magnetron is arranged at the lower part of the lower magnetic pole of the magnetron, and is sealed and connected with the anode shell of the magnetron to form a lower sealed chamber. The metal cathode cover and the anode shell are tightly connected by welding, and the cathode seal The middle position of the lower part of the cover is provided with an opening for the lead-out wire of the cathode to pass through. A ceramic component is arranged at the lower end of the magnetron corresponding to the lower sealing chamber of the lower magnetic pole, and the ceramic component is tightly combined with the cathode cover forming the lower sealing chamber; two cathode lead-out lines p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com