Umbilical cable filling structure optimization method

An optimization method and umbilical cable technology, applied in the field of umbilical cables, can solve the problems of not being able to achieve the mechanical properties of lightweight umbilical cables, and achieve the effects of uniform loading of filling structures, obvious economic benefits, and material reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

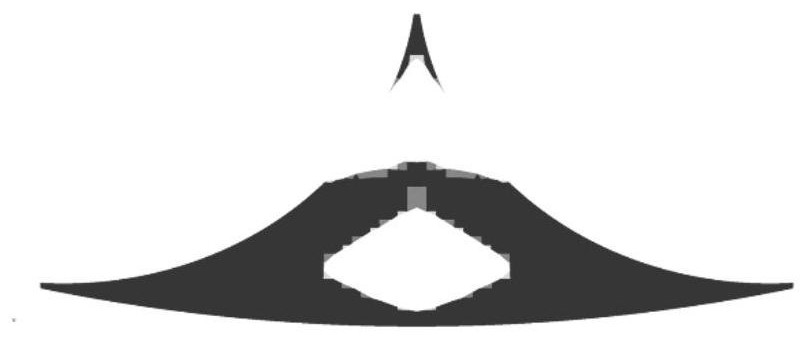

[0064] [1] Figure 3-Figure 6 Cross-sectional views of four typical infill structures shown, two of which are three-boundary types and the other two are four-boundary types. Create a two-dimensional plane model through SolidWorks software and import it into HyperMesh software;

[0065] [2] Mesh division in HyperMesh. Some shapes are divided into symmetrical meshes by means of mapping, and due to the irregularities of geometric shapes, some models choose triangular meshes with high geometric adaptability. Because the included angle of the corner part of the finite element model is too small, the generated unit software will cause singular calculation and analysis results, and the actual processing is inconvenient, so the outermost narrow corner unit is deleted.

[0066] [3] There are a variety of materials to choose from for the filling structure, common ones are high-density polyethylene (HDPE), polyvinylidene fluoride (PVDF), polyethylene (PE) and polyamide (PA). In the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com