Printed circuit board heat exchanger core for reducing stress

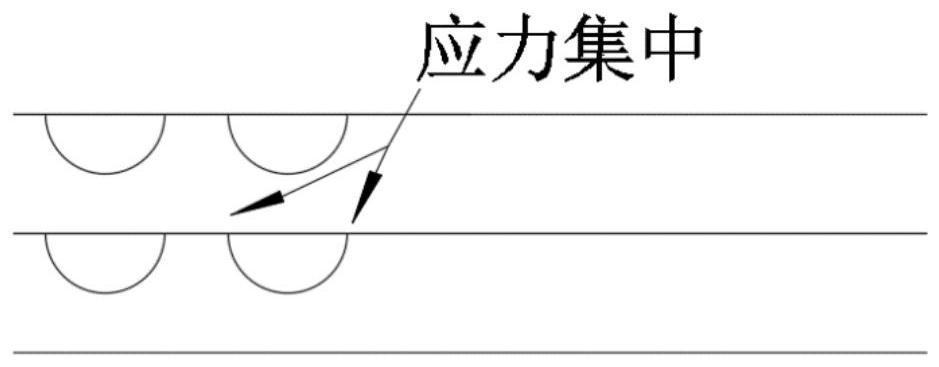

A technology for printed circuit boards and heat exchangers, applied in printed circuits, printed circuit components, circuit thermal devices, etc., can solve the problems of core scrap, excessive plastic deformation, material failure, etc., to eliminate sharp corners, reduce Thermal and mechanical stress, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with embodiment.

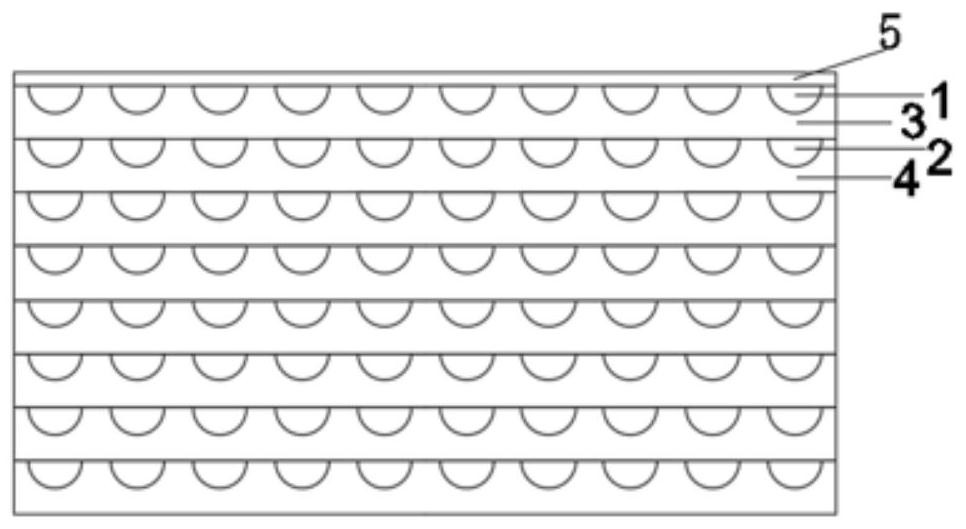

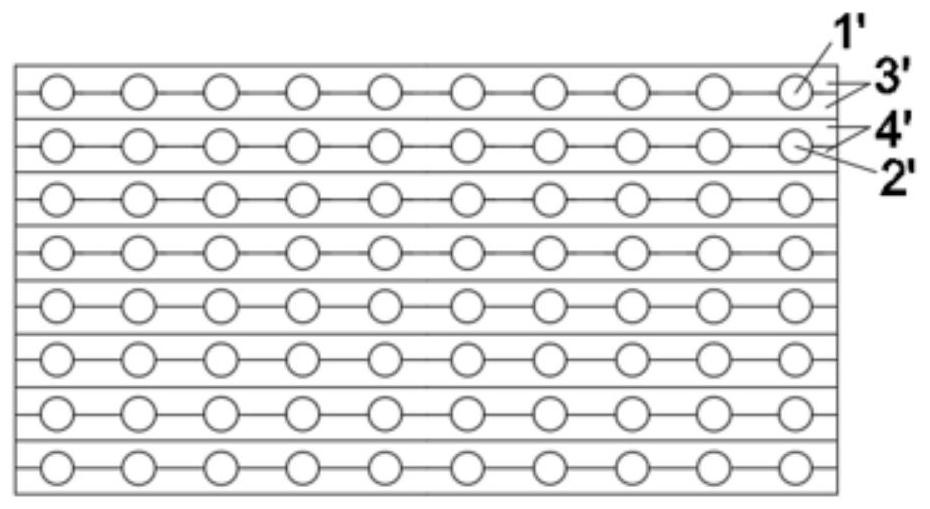

[0028] Such as Figure 2a and Figure 2b As shown, the present invention provides a printed circuit board heat exchanger core for stress reduction, said core comprising several hot plates 3' with hot fluid (high temperature fluid) passages 1' and cold fluid The cold plate 4' of the (cryogenic fluid) channel 2'. Described hot fluid (high-temperature fluid) passage 1 ' and cold fluid (low-temperature fluid) passage 2 ' adopt the photochemical etching method to etch the microchannel of semicircular cross-section on the metal sheet, and the shape of passage along flow direction can be straight line, positive (remainder) ) chord, Z (zigzag) or other combination forms, the etched metal sheets constitute the hot sheet 3' and the cold sheet 4'.

[0029] Such as image 3 As shown, the hot plate 3' and the cold plate 4' all have a surface A and a plane B with a semicircular arc, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com