Shaping method of silicon carbide powder particles

A silicon carbide powder and silicon carbide technology, applied in the direction of silicon carbide, carbide, etc., can solve the problems of low powder purity, increased environmental protection pressure, and complex shaping equipment, so as to avoid the introduction of impurities, increase the diffusion rate, and shape the effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

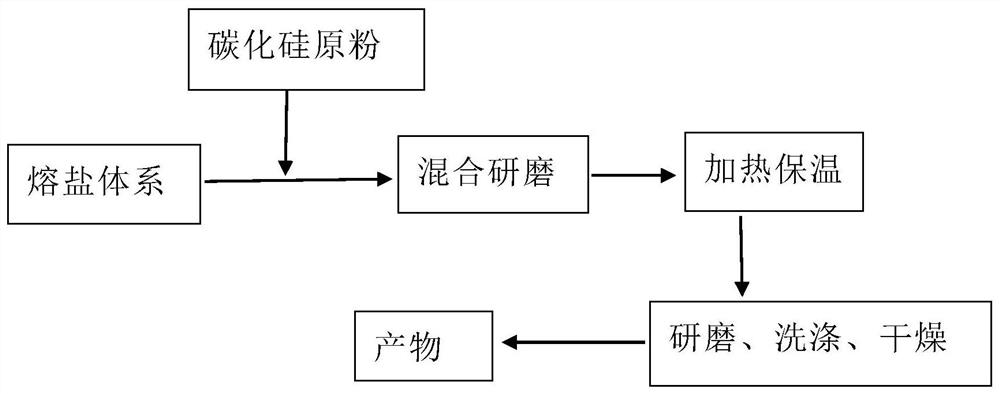

[0031] This embodiment includes the following steps:

[0032] Step 1. Mixing ratio: mix the soluble inorganic salt and silicon carbide raw powder according to the mass ratio of 1:1, grind them evenly, and then dry them at 105°C to obtain the mixture; the soluble inorganic salt is prepared by sodium nitrate and potassium nitrate according to 1:1 mass ratio composition; the silicon carbide raw powder is D50=37.6μm, and the tapped bulk density is 1.70g / cm 3 β-SiC powder;

[0033] Step 2, high-temperature melting treatment: place the mixture obtained in step 1 in a high-temperature furnace, heat it to 300°C and keep it for 24 hours to obtain a melt;

[0034] Step 3, product treatment: Cool the molten material obtained in step 3 to room temperature, take it out and grind it to obtain abrasive particles, and then stir and wash it with distilled water in a constant temperature water bath at 60°C for several times until the pH of the washing liquid is neutral. Incubate in a constant...

Embodiment 2

[0040] This embodiment includes the following steps:

[0041] Step 1. Mixing ratio: mix the soluble inorganic salt and silicon carbide raw powder according to the mass ratio of 1:0.8, grind them evenly, and then dry them at 105°C to obtain the mixture; the soluble inorganic salt is prepared by sodium nitrate and potassium nitrate according to 1:1.5 mass ratio composition; the silicon carbide raw powder is D50=37.6μm, and the tapped bulk density is 1.70g / cm 3 β-SiC powder;

[0042] Step 2, high-temperature melting treatment: the mixture obtained in step 1 is placed in a high-temperature furnace, heated to 390°C and kept for 10 hours to obtain a melt;

[0043] Step 3, product treatment: Cool the molten material obtained in step 3 to room temperature, take it out and grind it to obtain abrasive particles, and then stir and wash it with distilled water in a constant temperature water bath at 60°C for several times until the pH of the washing liquid is neutral. Keep warm in a con...

Embodiment 3

[0046] This embodiment includes the following steps:

[0047] Step 1. Mixing ratio: mix the soluble inorganic salt and silicon carbide raw powder according to the mass ratio of 1:0.5, grind them evenly, and then dry them at 105°C to obtain the mixture; the soluble inorganic salt is prepared by sodium nitrate and potassium nitrate according to Composition with a mass ratio of 1:2; the raw silicon carbide powder is D50=37.6μm, and the tapped bulk density is 1.70g / cm 3 β-SiC powder;

[0048] Step 2, high-temperature melting treatment: place the mixture obtained in step 1 in a high-temperature furnace, heat it to 420° C. and keep it for 4 hours to obtain a melt;

[0049] Step 3, product treatment: Cool the molten material obtained in step 3 to room temperature, take it out and grind it to obtain abrasive particles, and then stir and wash it with distilled water in a constant temperature water bath at 60°C for several times until the pH of the washing liquid is neutral. Keep warm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com