Triple screw for correcting tooth profiles through arcs

A three-screw and screw technology, used in rotary piston/swing piston pump components, rotary piston machinery, machines/engines, etc., can solve the problem of increased processing difficulty, increased leakage of screw pumps, and tool life. Shortening and other problems to achieve the effect of reducing processing difficulty, stabilizing volumetric efficiency, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

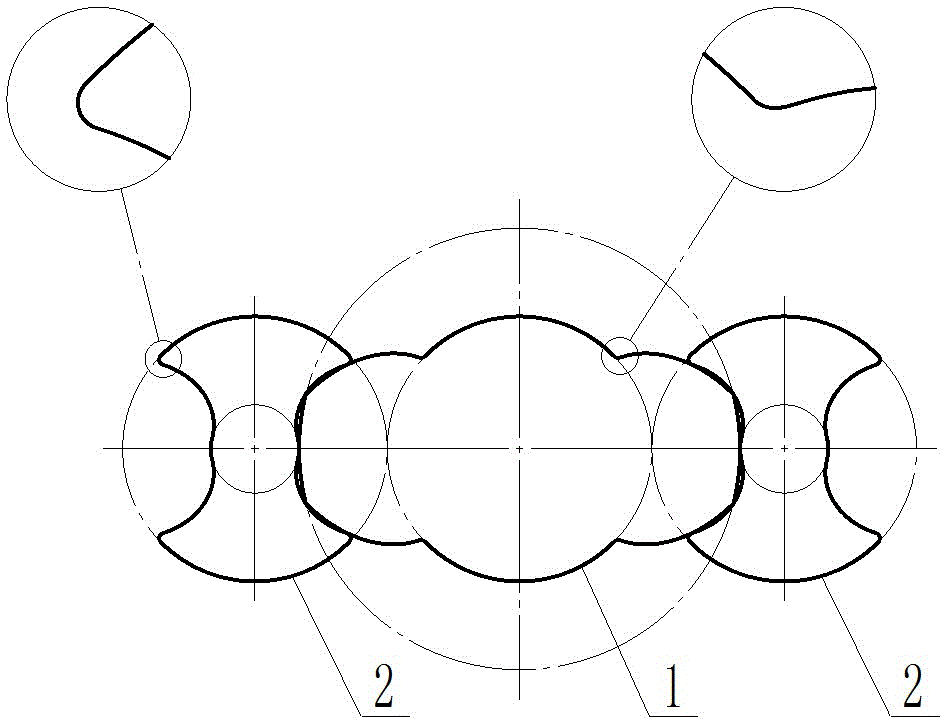

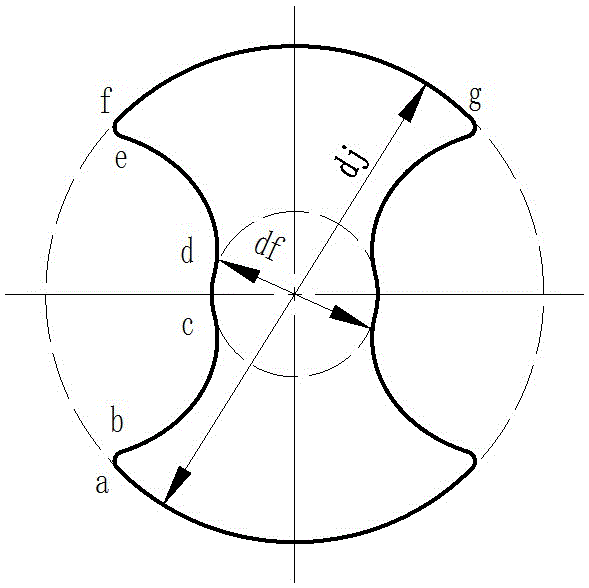

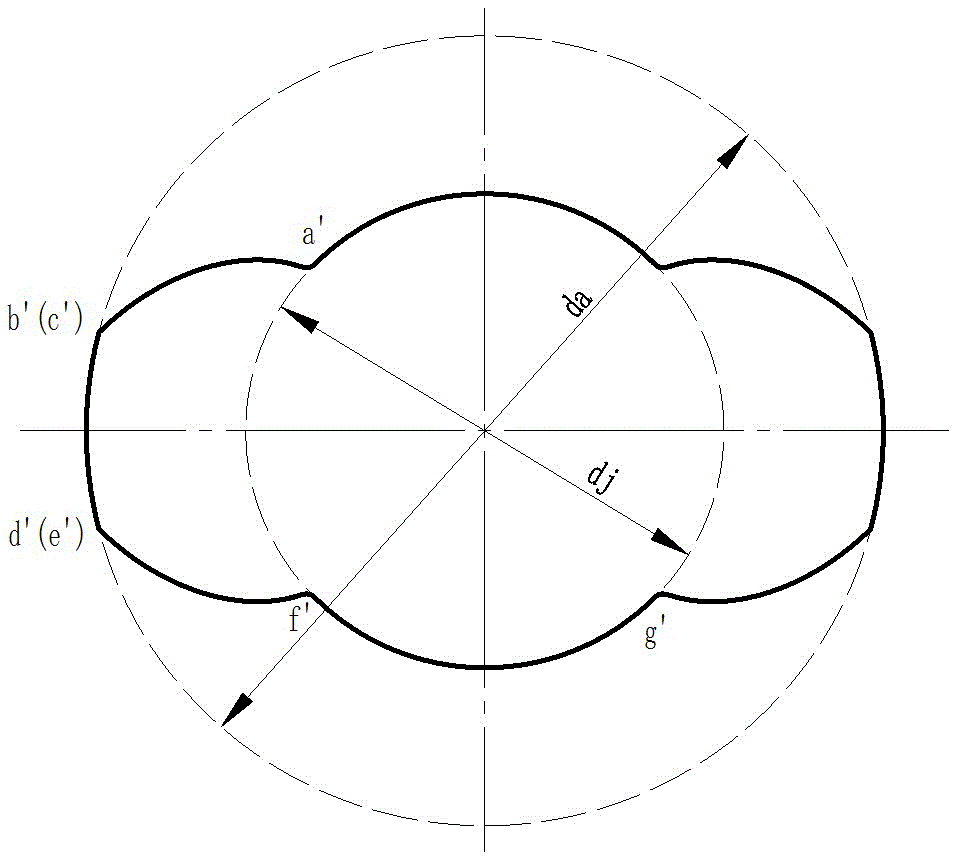

[0024] See Figure 7 , Figure 8 with Picture 9 , The original three-screw pump tooth profile adopts a radial straight line correction three-screw tooth profile, the original driven screw 4 has the same tooth profile on each screw end face, one of which is formed by a radial straight line a 1 b 1 , Long outer cycloid b 1 c 1 , Root circle c 1 d 1 , Long outer cycloid d 1 e 1 , Radial line e 1 f 1 And addendum circle f 1 g 1 Composition; the original driving screw 3 has the same tooth profile on each end of the screw, one of which is formed by the outer cycloid a 1 ˊB 1 ˊ, short epicycloid b 1 ˊC 1 ˊ, addendum circle c 1 ˊD 1 ˊ, short epicycloid d 1 ˊE 1 ˊ, epicycloid e 1 ˊF 1 ˊAnd root circle f 1 ˊG 1 composition. Due to the radial straight line in the 4 tooth profile of the original driven screw a 1 b 1 And e 1 f 1 There are sharp corners at the two ends of the screw, which are easy to wear when meshing with the original active screw 3, causing leakage to increase, causing the ...

Embodiment 1

[0031] Example one, diameter d of the tip circle of the driving screw 1 a =100mm, the following table lists the design dimensions of the driving screw 1 and driven screw 2 of this specification, unit: mm. In this embodiment, in order to reduce the leakage area and maintain a high volumetric efficiency, the excessive arc radius r of the driven screw 2 o =0.9mm.

[0032]

Embodiment 2

[0033] The second embodiment, the diameter d of the tip circle of the driving screw 1 a =40mm, the following table lists the design dimensions of the driving screw 1 and driven screw 2 of this specification, unit: mm. In this embodiment, in order to increase the wear resistance of the driven screw 2, the excessive arc radius r of the driven screw 2 o =0.6mm.

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com