Chopper structure

A chopping knife and arc-shaped technology, which is applied in the field of semiconductor packaging, can solve problems such as scratches on welding wires and affect the welding quality of semiconductor products, and achieve the effects of not being easy to detach, improving welding force, and avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

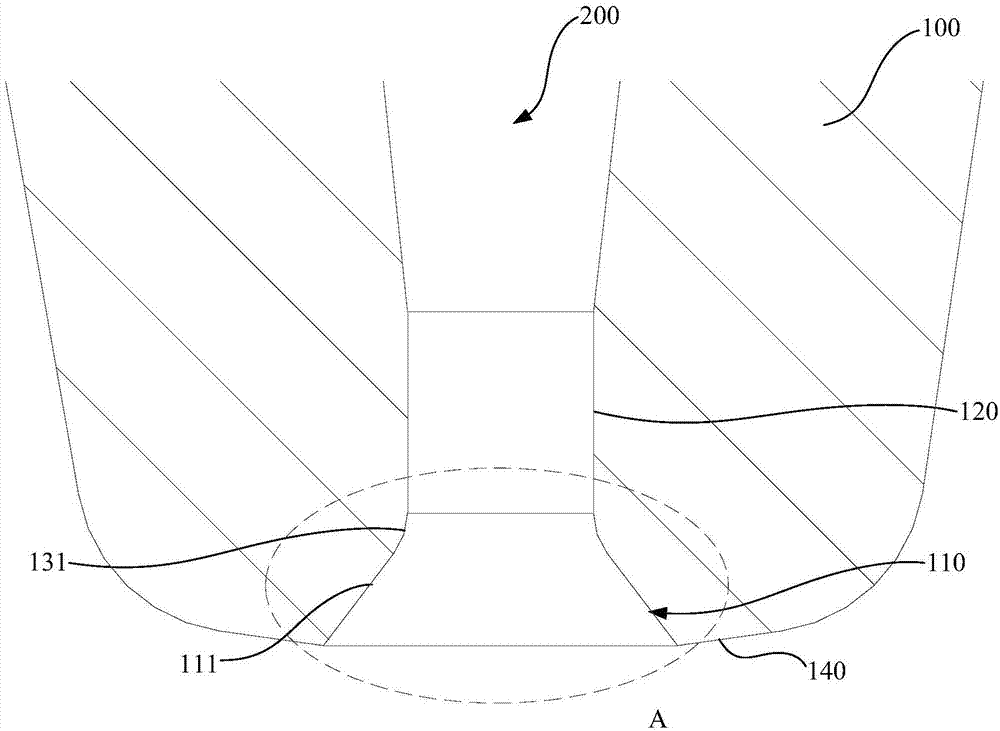

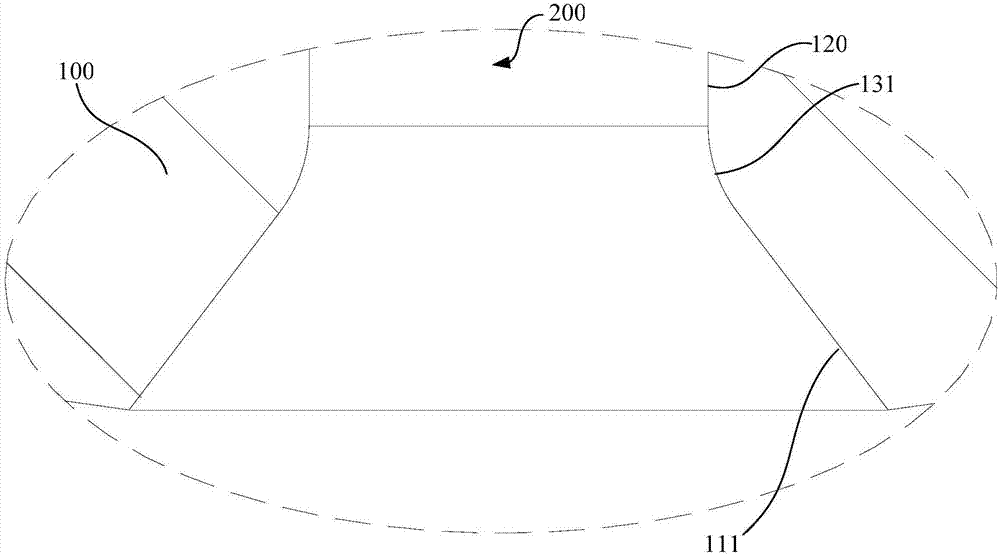

[0028] see also figure 1 with figure 2 , the tapered wall 110 includes a first tapered wall 111, the first tapered wall 111 is close to the end of the rivier body 100, the top end of the first arc transition wall 131 is connected with the bottom end of the inner cavity wall 120, and the first arc transition The bottom end of the wall 131 is connected with the top end of the first tapered wall 111 . The first cone wall 111 is surrounded by an inner chamfer (that is, a single inner chamfer). The inner cavity wall 120 defines the inner hole, and the first arc-shaped transition wall 131 defines the transition hole between the inner chamfer and the inner hole.

[0029] The first arc-shaped transition wall 131 is arc-shaped, and its radius is R, wherein the value range of R is: 2 μm ≤ R ≤ 60 μm. In this embodiment, the value of the radius R of the first arc-shaped transition wall 131 is 30 μm. Certainly, there are other value points, for example, the value of the radius R of th...

Embodiment 2

[0033] refer to Figure 5 , the tapered wall 110 includes a second tapered wall 112 and a third tapered wall 113 . The second cone wall 112 is close to the end of the riving tool body 100, the third cone wall 113 is coaxially arranged with the second cone wall 112 and the inner cavity wall 120, and the third cone wall 113 is located between the second cone wall 112 and the inner cavity wall 120 between. Specifically, the bottom end of the inner cavity wall 120 is connected to the top end of the first arc-shaped transition wall 131, the bottom end of the first arc-shaped transition wall 131 is connected to the top end of the third cone wall 113, and the bottom end of the third cone wall 113 It is connected with the top end of the second cone wall 112 .

[0034] In fact, the second cone wall 112 and the third cone wall 113 are respectively surrounded by an inner chamfer, that is, a double inner chamfer. Due to the existence of the double inner chamfer, the scratching of the ou...

Embodiment 3

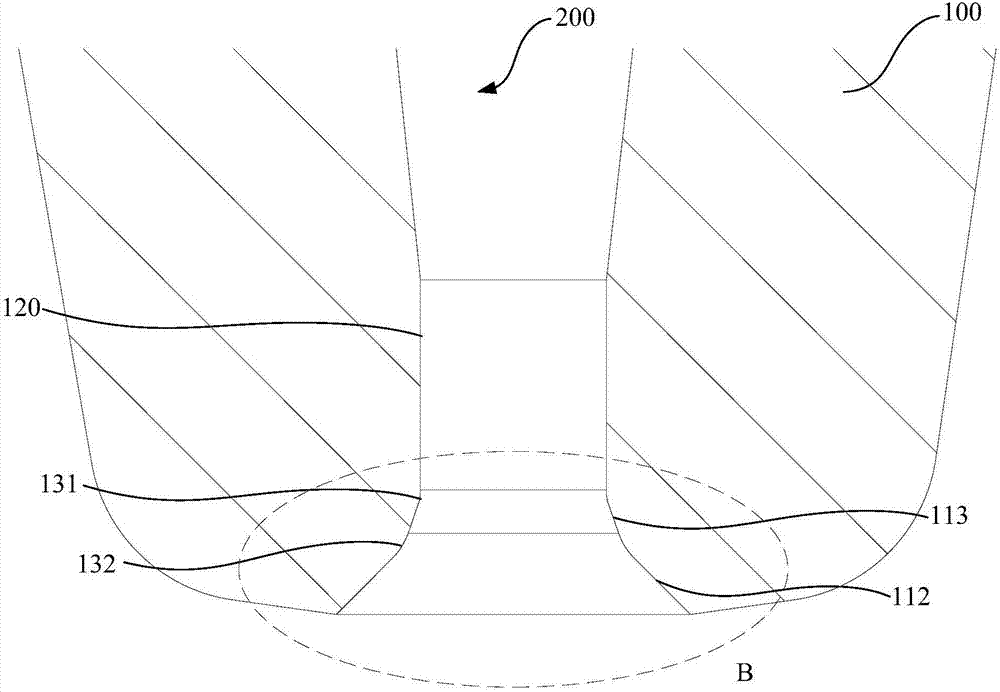

[0038] see also image 3 and Figure 4 , the tapered wall 110 includes a second tapered wall 112 , a third tapered wall 113 and a second arc-shaped transition wall 132 . The second cone wall 112 is close to the end of the riving tool body 100, the third cone wall 113 is coaxially arranged with the second cone wall 112 and the inner cavity wall 120, and the third cone wall 113 is located between the second cone wall 112 and the inner cavity wall 120 between. Specifically, the bottom end of the inner cavity wall 120 is connected to the top end of the first arc-shaped transition wall 131, the bottom end of the first arc-shaped transition wall 131 is connected to the top end of the third cone wall 113, and the bottom end of the third cone wall 113 It is connected with the top end of the second arc-shaped transition wall 132 , and the bottom end of the second arc-shaped transition wall 132 is connected with the top end of the second tapered wall 112 .

[0039] Since the second a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com