Anti-reflection, low-radiation and easy-cleaning coated glass capable of roasting and bending and manufacture method thereof

A technology of low-radiation coating and coated glass, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve problems such as disturbing driving sight, not easy to clean, affecting driving safety, etc., to maintain Clean and bright, eliminate the effect of interfering with the driving line of sight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

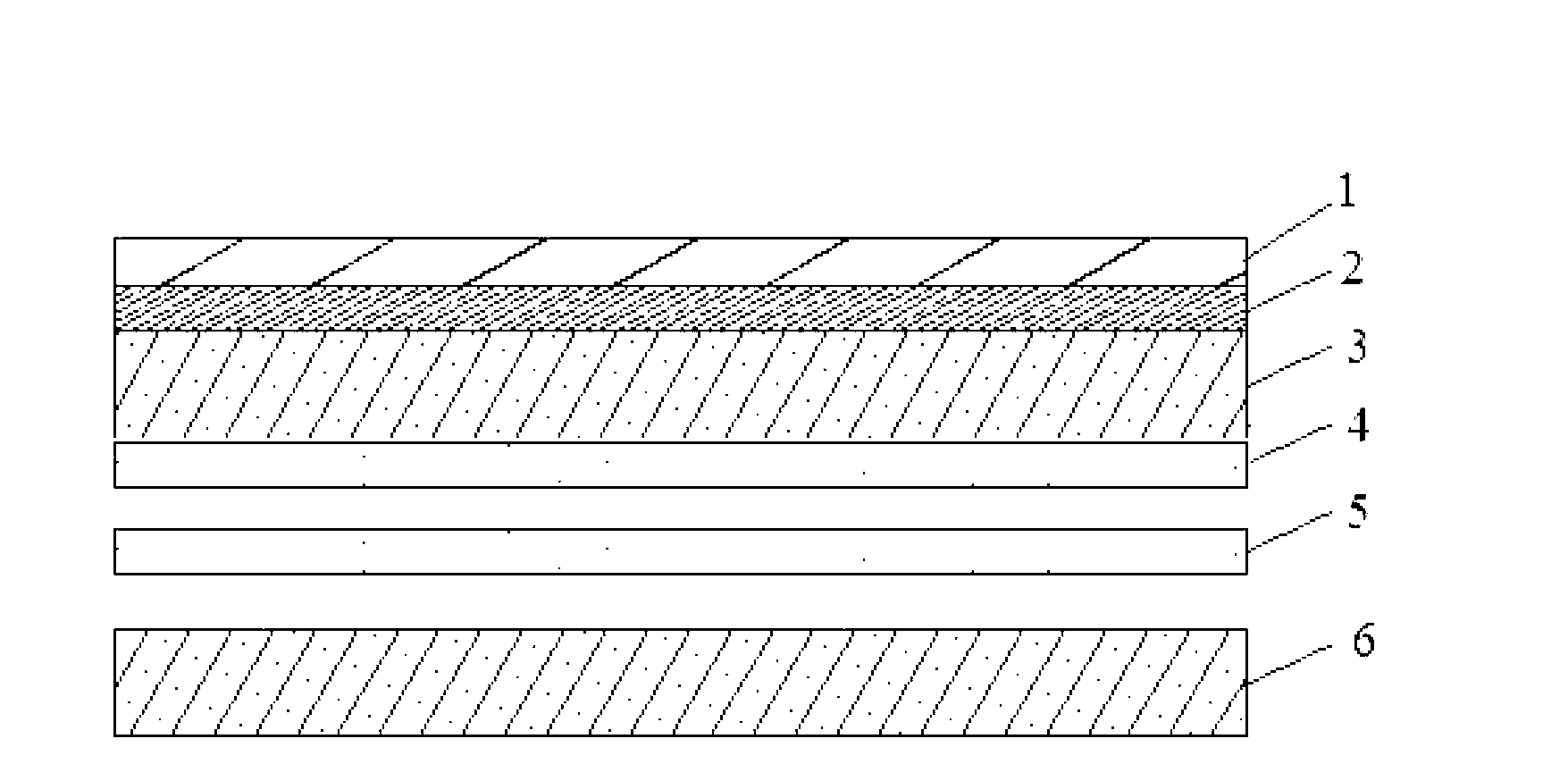

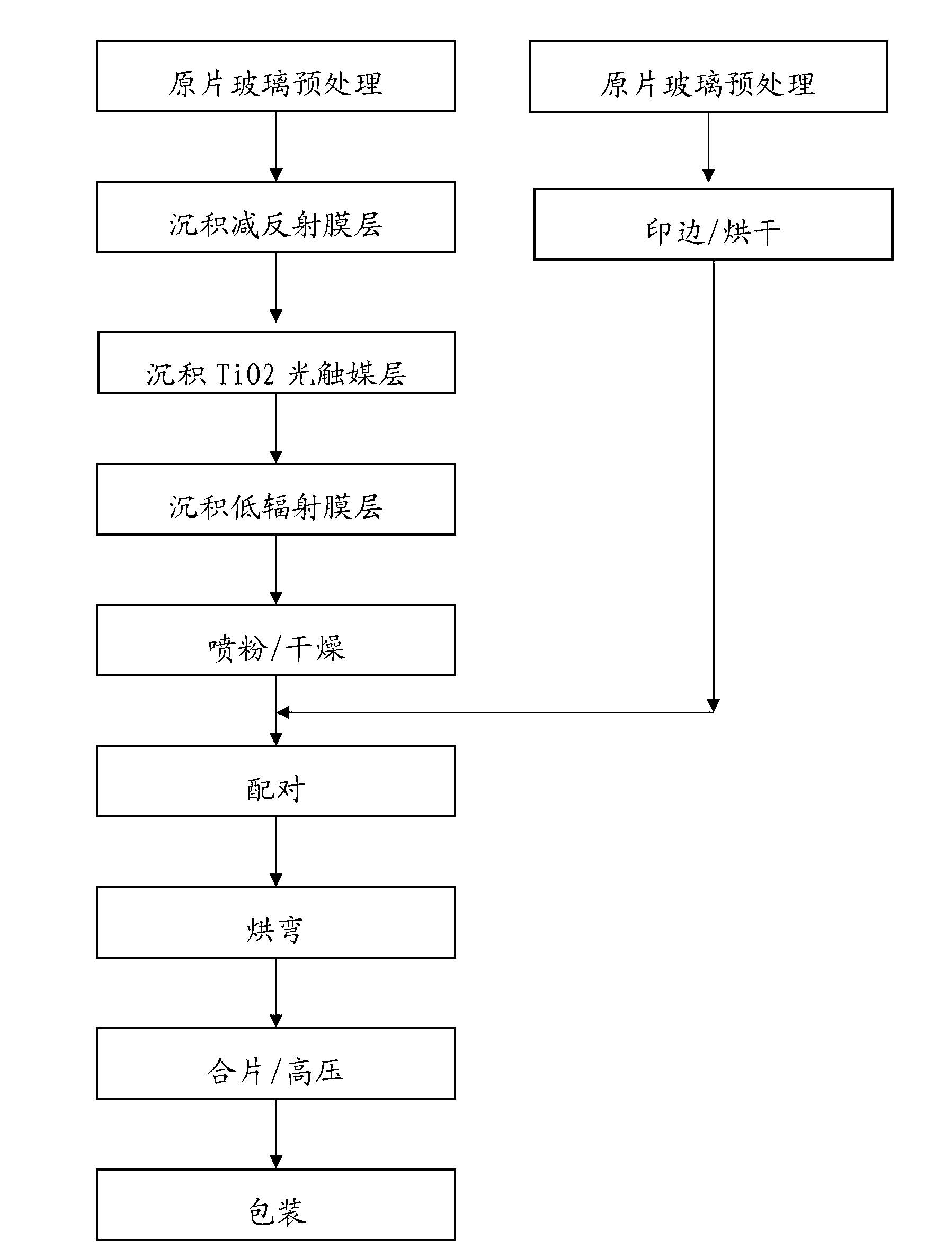

[0043] Such as figure 1 As shown, a kind of bakeable anti-reflection low-radiation and easy-to-clean coated glass is composed of anti-reflection and low-radiation coated glass, polyvinyl butyral (PVB) 5, and glass plate B6. Reflective low-radiation and easy-to-clean coated laminated glass, wherein the structure of the anti-reflective low-radiation coated glass is: TiO layered sequentially from top to bottom 2 The photocatalyst layer 1, the antireflection film layer 2, the glass plate A3 and the low radiation film layer 4 are composed.

[0044] The TiO 2 The thickness of photocatalyst layer 1 is 50-200nm; the thickness of anti-reflection film layer 2 is 219-230nm; the thickness of glass plate A3 is 1.6-2.5mm, the thickness of low-radiation film layer 4 is 80-130nm, and the thickness of PVB is 0.76mm , the thickness of the glass plate B is 1.6-2.5mm.

[0045] The anti-reflection film layer is composed of the first high refractive index film layer, the first low refractive ind...

Embodiment 2

[0066] A bendable, anti-reflection, low-radiation, and easy-to-clean coated glass. The glass is composed of anti-reflection, low-emission coated glass, polyvinyl butyral (PVB), and glass plate B in sequence. Clean coated laminated glass, wherein the structure of the anti-reflection and low-emissivity coated glass is: TiO layered sequentially from top to bottom 2 It consists of a photocatalyst layer, an anti-reflection film layer, a glass plate A and a low-radiation film layer.

[0067] The TiO 2 The thickness of the photocatalyst layer is 50nm; the thickness of the anti-reflection film layer is 219nm; the thickness of the glass plate A is 1.6mm, the thickness of the low-emissivity film layer is 92nm, the thickness of the PVB is 0.76mm, and the thickness of the glass plate B is 1.6mm.

[0068] The anti-reflection film layer is composed of a first high-refractive-index film layer, a first low-refractive-index film layer, a second high-refractive-index film layer and a second lo...

Embodiment 3

[0076] A bendable, anti-reflection, low-radiation, and easy-to-clean coated glass. The glass is composed of anti-reflection, low-emission coated glass, polyvinyl butyral (PVB), and glass plate B in sequence. Clean coated laminated glass, wherein the structure of the anti-reflection and low-emissivity coated glass is: TiO layered sequentially from top to bottom 2 It consists of a photocatalyst layer, an anti-reflection film layer, a glass plate A and a low-radiation film layer.

[0077] The TiO 2 The thickness of the photocatalyst layer is 200nm; the thickness of the anti-reflection film layer is 230nm; the thickness of the glass plate A is 2.5mm, the thickness of the low-emissivity film layer is 130nm, the thickness of the PVB is 0.76mm, and the thickness of the glass plate B is 2.5mm.

[0078] The anti-reflection film layer is composed of a first high-refractive-index film layer, a first low-refractive-index film layer, a second high-refractive-index film layer and a second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com